Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The global stud welding machine market was valued to reach a market size of USD 1.29 Billion in 2025. The industry is expected to grow at a CAGR of 4.23% during the forecast period of 2026-2035. The market is driven by a growing construction sector, automotive sector, expanding demand for renewable energy sources and shipbuilding industry. These sectors are the key drivers of the stud welding machine market, thus aiding the market to attain a valuation of USD 1.95 Billion by 2035.

Base Year

Historical Period

Forecast Period

The superior strength and reliability of stud welds make this welding process highly suitable for the construction sector. Stud welding is applied in areas such as highway barriers, guardrails, and road signs for durability and to withstand traffic. In 2024, highway and bridge construction activity in the USA was up 9.2%, reaching record levels of USD 108 billion, aiding the demand for stud welding machines.

By 2030, the volume of global construction output is expected to grow by 85% to USD 15.5 trillion. Stud welding machines are energy efficient, making them an ideal choice for industry welding solutions. These machines provide fast, efficient, and versatile permanent bond between materials.

In the shipbuilding industry, stud welding is a widely used joining process. Shipbuilding companies use stud welding machines for various applications including wire and cable management, fluid lines, control panels and electrical systems and insulation. In 2023, China, South Korea, and Japan accounted for 92% of total shipbuilding globally. In the same year, the United States had 11 million electric recreational boats, and the Europe accounted for 6.5 million electric recreational boats.

Compound Annual Growth Rate

4.23%

Value in USD Billion

2026-2035

*this image is indicative*

The global stud welding market continues to grow with increasing demand for construction in economies such as China, the United States and India. In the automotive manufacturing, the no-hole fastening method is gaining popularity to minimise the risk of corrosion and leaking. In 2025, the convergence of AI-driven production systems and the scaling of EV capabilities are expected to drive the growth of the automotive sector, further supporting the demand for stud welding machines.

Further, stud welding system market is evolving with the increasing use of lightweight materials. Hyconnect’s FAUSST technology, launched in September 2024, enables high-strength, adhesive-free metal-composite connections by integrating weldable inserts, supporting the stud welding machine market growth.

Manufacturers are investing in automation to enhance efficiency and quality. Studs are fixed onto the parent material without perforation using this equipment. Leading manufacturing companies use stud welding machines for attaching machinery guards, fixing cover plates and maintenance hatches, and mounting handles. In 2023, the global manufacturing sector accounted for 15% of the global GDP.

Additionally, machine manufacturers are offering an online demo of stud welding equipment and equipment sales and rental services to gain consumer attention, bolstering the stud welding machine adoption.

The global stud welding machine market development is supported by the expansion in electronics manufacturing and its growing application in the shipbuilding industry.

In the electronics sector, stud welding is employed for its versatility and precision. Stud welding enables precise PCB mounting in automation, data transmission, and test equipment, ensuring stability, reducing vibration risks, and enhancing system performance. In 2023, with a 33% share of worldwide electronics manufacturing and a USD 1,368 billion total value, China was the leading electronics producer in the world, followed by Taiwan with a 12% share of world production and a total value of USD 507 billion.

Stud welded joints offer great durability and weather resistance, making them particularly well-suited for the harsh conditions, especially moisture, of the open sea. As it can securely affix components to sensitive materials and uneven surfaces without sacrificing strength, this welding technology offers a dependable fastening solution for shipbuilding. Furthermore, stud welding ensures structural integrity in crucial regions by precisely joining delicate features. It is the best option for establishing durable, waterproof connections in shipbuilding due to its adaptability and strong performance in maritime settings.

Technological advances, extensive application in end use sectors, and regulatory compliance drive stud welding machine market expansion.

Automated stud welding machines are gaining popularity over traditional machines due to efficiency. These machines are increasingly being adopted in industries due to their efficiencies. These machines can boast up to 5 welding heads and dual controllers to increase speed. They have fast welding rates of up to 60 studs per minute.

Stud welding machines are used for grounding, electrical connections and attaching studs to mount fragile components without damaging sensitive surfaces. In 2023, with a 33% share of worldwide electronics manufacturing and a USD 1,368 billion total value, China was the leading electronics producer globally.

In the ship building industry, stud welded joints provide durable and corrosion-resistant and capabilities to secure irregular surfaces, delicate materials, and intricate details. In 2023, China boasted the world’s largest shipbuilding industry, and China’s marine economy exceeded USD 1.3 trillion (9 trillion yuan).

To guarantee constant quality control, stud welding machine manufacturers follow industry standards established by organisations such as the American Welding Society (AWS) and ISO. These standards regulate several areas, including as safety measures, welding techniques, and equipment design. By adhering to these rules, manufacturers ensure that their stud welding machines function securely and satisfy strict performance standards, guaranteeing dependability and efficiency in welding applications across many sectors.

The latest trend in the stud welding machine market includes the growing popularity of automated stud welding machines. These machines range from semi to full automation depending on buyers’ requirements. Automated stud welding machines can boast up to 5 welding heads and dual controllers to increase speed. They have fast welding rates of up to 60 studs per minute. These machines are ideal for long and short production runs. These effortlessly programmable computer numerical control (CNC) machines have a high accuracy level; they can also weld several components simultaneously to increase operational efficiency and cost effectiveness.

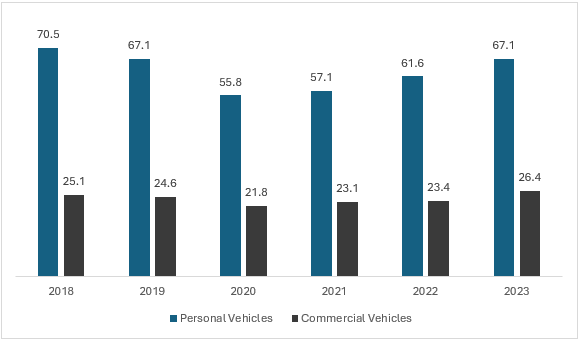

Increased automotive manufacturing is another essential driver in this market. Automotive manufacturers can use stud weld equipment for diverse automotive applications such as Power Steering and insulation. Stud welding contributes to the stable attachment of brackets and support structures, ensuring smooth and reliable steering performance. In 2023, China was the largest automotive producer, producing about 30.2 million units, of which passenger vehicles accounted for 26 million and commercial vehicles about 4 million units.

Figure: Global Automotive Manufacturing (in Million Units), 2018-2023

In the structural applications, including bridges, and high-rise buildings, stud welding machines provide precise way to attach metal studs or anchors to large steel structures or concrete, offering the most efficient stud joining system. Stud welding is used in a variety of construction tasks, such as building and bridge construction, among others. For safer roads and structures, strong welding is also necessary for underground systems like sewer pipes and other subsurface utilities. Asia Pacific is a key region for construction market, especially driven by China and India, contributing to the stud welding machine market revenue.

Stud welding is a widely used fastening process in the renewable energy industry, particularly in the construction and maintenance of wind farms and solar panel mounting structures. The fabrication of wind turbine blades also uses stud welding. The blades must be able to survive severe weather conditions and have high aerodynamic efficiency. Brackets, root sections, and reinforcements are fixed to the blade structure through stud welding, which produces a seamless, smooth surface that improves aerodynamic performance. In 2023, global new investment in renewable power and fuels reached a record high of an estimated USD 622.5 billion, an 8.1% increase compared to 2022, primarily driven by the global rise in solar photovoltaic (PV) installations.

Global stud welding machine market challenges include shortage of welding labours and lack of maintenance. The operation of stud welding machine requires skilled operators. The shortage in skilled labour could result in inefficient operations. Furthermore, regular maintenance is usually needed for parts like short guns, cabling, and power sources. The efficiency of the machine might be significantly decreased by dust and filth, which can cause serious issues for power supplies.

“Global Stud Welding Machine Market Report and Forecast 2026-2035” offers a detailed analysis of the market based on the following segments:

On the basis of type of arc ignition, the market can be divided into the following:

Based on material, the market can be segmented into the following:

On the basis of stud diameter, the market can be divided into the following:

By operation, the market can be bifurcated into the following:

On the basis of distribution channel, the market can be divided into the following:

Based on application, the market can be divided into:

Based on region, the market can be segregated into:

Market Analysis by Arc Ignition

Drawn arc stud welding is expected to hold a significant share in the global stud welding machine industry due to its energy efficiency and cost effectiveness. Manufacturers are introducing stud welding machines to increase productivity and save energy in order to take advantage of the expanding need for environmentally friendly welding solutions across a range of industries. In order to address this, Taylor Studwelding Systems Ltd. introduced the SPi-10 drawn arc stud welder in late 2024. Its single-phase electricity and inverter technology ensure accuracy for welding that is horizontal, overhead, and short-cycle.

Market Analysis by Material

Welding technology selection is critical for welding advanced steels, aluminium, and magnesium alloys that are widely used in modern vehicles. The expanding application of steel in sectors such as automotive, shipbuilding and construction supports the demand for steel welding, aiding stud welding machines demand. Stud welding demand is rising in shipbuilding and oil and gas for high-strength, durable joints, ensuring reliability in marine and offshore structures.

Market Analysis by Stud Diameter

Electronics and micro-welding drive demand for small-diameter stud welding, essential for PCB components and precision instruments requiring high accuracy and reliability. In November 2024, Graphco introduced Automatic Stud Welding (ASW) technology on the Augusta F150R Pro CNC Cutting & Routing Table. Supporting studs from 2mm to 10mm wide and 6mm to 50mm long, ASW enhances precision and labour reduction.

Market Analysis by Operation

The semi-automated process for high-speed welding of bulk studs is gaining traction in automated manufacturing environments focused on efficiency and productivity. Semi-automated welding machines, commonly used in infrastructure projects, offer fast and efficient performance, enabling the welding of up to 2,000 studs per day. Their ability to require less skill from operators further enhances their widespread adoption. The growth of the infrastructure sector further supports the stud welding machine market.

Market Analysis by Distribution Channel

Businesses can increase their revenue share by cutting out intermediaries through direct distribution. Companies can keep more of the sales price by avoiding intermediaries, which greatly increases profit margins on each transaction and raises total profitability. Financial success is further enhanced by this direct strategy, which also gives you more control over pricing, client connections, and brand positioning.

Market Analysis by Application

Shipbuilding is a significant segment in the stud welding machines market due to its efficiency. Stud welding is widely used in shipbuilding as it makes it possible to avoid overlapping components, which speeds up and simplifies the construction process. This approach is favoured by shipbuilders because it improves the general agility and efficiency of vessels. A growing need for energy-efficient vessels and greater international trade are driving the shipbuilding industry's growth and propelling the market's rise. Stud welding is essential to satisfying these changing industrial demands as performance and sustainability rise to the top of the priority list.

North America Stud Welding Machine Market Dynamics

Automatic stud welding technology is gaining traction in the North American stud welding machine market as it provides customers ease-of-use and maximum productivity. The automated setup allows operators to achieve flawless welds without the need for manual intervention, allowing them to focus on other critical tasks. In August 2023, Hilti North America, used this as an opportunity to launch the FX 3-A Cordless stud fusion system which is 75% faster than traditional welding methods.

Europe Stud Welding Machine Market Dynamics

The Europe stud welding machine market is expanding due to the growth in construction, shipbuilding and automotive sectors. In 2024, Germany was home to around 130 shipyards that provide services for commercial, inland, recreational craft building, naval shipbuilding, and general repairs and conversions. In 2024, the construction sector was a cornerstone of the EU economy, contributing around 9% of the EU’s GDP, and supporting 24.2 million jobs. This robust economic foundation enhances the demand for stud welding technologies, essential for the high-quality, efficient production processes in these industries.

Asia Pacific Stud Welding Machine Market Opportunities

The Asia Pacific stud welding machine market is expanding due to the growth in construction, shipbuilding and automotive sectors. The region is home to some of the largest automotive manufacturers such as China, Japan, India and South Korea, expanding stud welding machine applications. In 2024, China, South Korea, and Japan accounted for over 85% of the global shipbuilding industry. Furthermore, global production by Japanese electronics and IT companies is expected to lift 4% year-on-year in 2025 to USD 284.55 billion driven by a rising demand for electronic components, semiconductors, and solution services.

Latin America Stud Welding Machine Market Insights

The Latin America stud welding machine market is gaining traction due to rapid urbanisation and government investments in infrastructure projects. 2030, Latin America and the Caribbean need to invest over USD 2.2 trillion in sectors like energy, transportation, and telecommunications to meet SDG goals. The growth in Brazil and Mexico’s automotive manufacturing and Argentina’s construction boom further expands the demand for stud welding machine.

Middle East and Africa Stud Welding Machine Market Drivers

The Middle East and Africa stud welding machine market is driven by rising demand for energy from renewable sources. In the renewable energy sector, stud welding is a common attachment technique, especially for building and maintaining wind farms and solar panel mounting systems. Furthermore, Saudi Arabia's Vision 2030 is driving investments in infrastructure, tourism, and industrial projects like NEOM and The Red Sea Project, increasing the demand for stud welding machines in large-scale construction.

The global stud welding machine market players are concentrating in developing automated stud welding machines, offering services and technical support to gain competitive edge.

Founded in 1984, the company is headquartered in the United Kingdom. The company is recognised as the UK's sole designer and manufacturer of stud welding machines and accessories. Renowned for its expertise, the company has established itself as the leading supplier, designer, and manufacturer of stud welding equipment in the UK.

Köster & Co. GmbH specialises in advanced stud welding technologies, including stud welding with ceramic rings, short-time stud welding, stud welding with protective gas, and stud welding with capacitance ignition, delivering innovative and reliable solutions for diverse industrial applications.

Founded in 1970 and headquartered in Germany, the company is recognised for providing high-quality, high-performance stud welding products from a single source, supported by numerous awards and certifications. Its product portfolio includes drawn arc, capacitor discharge, magnetic field stud welding, and others.

Founded in 2018, and located in Germany, Bolte GmbH, emerged as an independent company after spinning off the Stud Welding Systems division of AS Schöler + Bolte GmbH. The company offers stud welding units under three categories namely Drawn arc stud welding units, Inverter drawn arc stud welding units and Capacitor discharge stud welding units.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

Other key players in the global stud welding machine market are HBS Bolzenschweiss-Systeme GmbH & Co. KG, Image Industries Inc., TFP Corporation, China IKING Industrial Group Co., Ltd, STUDMASTER, and STANLEY Engineered Fastening, among others.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

In 2025, the global stud welding machine market reached an approximate value of USD 1.29 Billion.

The global stud welding machine market is assessed to grow at a CAGR of 4.23% between 2026 and 2035.

The global stud welding machine market is estimated to witness healthy growth in the forecast period of 2026-2035 to reach a value of around USD 1.95 Billion by 2035.

The major drivers of the market include the growing automotive and construction sectors, rising technological advancements, and the transition towards automatic welding systems.

The key trends aiding the growth of the market include increasing use of heavy machinery, the rising use of stud welding machines in producing and installing automotive components, and versatile applications of the machine.

The major regional markets include North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa.

The various distribution channels include direct and indirect.

The key players in the market include STANLEY Engineered Fastening, Taylor Studwelding Systems Limited, Köster & Co. GmbH, Heinz Soyer Bolzenschweißtechnik, Bolte GmbH, TFP Corporation, Image Industries, Inc, China IKING Industrial Group Co., Ltd., STUDMASTER, and HBS Bolzenschweiss-Systeme GmbH & Co. KG, among others.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2025 |

| Historical Period | 2019-2025 |

| Forecast Period | 2026-2035 |

| Scope of the Report |

Historical and Forecast Trends, Industry Drivers and Constraints, Historical and Forecast Market Analysis by Segment:

|

| Breakup by Type of Arc Ignition |

|

| Breakup by Material |

|

| Breakup by Stud Diameter |

|

| Breakup by Operation |

|

| Breakup by Distribution Channel |

|

| Breakup by Application |

|

| Breakup by Region |

|

| Market Dynamics |

|

| Competitive Landscape |

|

| Companies Covered |

|

Datasheet

One User

USD 2,499

USD 2,249

tax inclusive*

Single User License

One User

USD 3,999

USD 3,599

tax inclusive*

Five User License

Five User

USD 4,999

USD 4,249

tax inclusive*

Corporate License

Unlimited Users

USD 5,999

USD 5,099

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share