Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The steel casting market attained a value of USD 35.29 Billion in 2025. The market is expected to grow at a CAGR of 5.50% during the forecast period of 2026-2035. By 2035, the market is expected to reach USD 60.28 Billion.

Infrastructure development worldwide fuels demand for steel castings used in heavy machinery, structural components, and building equipment. Large-scale projects like bridges, tunnels, and commercial buildings require reliable, durable parts capable of withstanding harsh environments. Steel castings provide strength and versatility needed for pumps, valves, cranes, and other construction machinery. Urbanization and government initiatives promoting smart cities and industrial growth amplify this trend.

Technological progress is significantly influencing the steel casting market outlook. Innovations, such as 3D printing for mold design, improved computer-aided casting simulations, and automation increase precision, reduce waste, and shorten lead times. In September 2022, ExOne introduced the X1 Tooling range, the world's largest offering of industrial-grade 3D printed tooling, including products for metal castings. These advancements enhance product quality and allow manufacturers to meet complex specifications across industries.

Base Year

Historical Period

Forecast Period

Compound Annual Growth Rate

5.5%

Value in USD Billion

2026-2035

*this image is indicative*

The accelerating EV market demands steel castings tailored for battery enclosures, electric motor components, and lightweight structural parts. As per International Energy Agency (IEA), electric car sales exceeded 3 million in the first quarter of 2024. Steel castings support the weight reduction goals critical for EV range and efficiency. Manufacturers focus on developing heat-resistant and corrosion-resistant alloys suitable for battery safety and longevity. This trend compels foundries to innovate in alloy composition and precision casting techniques.

Environmental concerns and regulations are pushing steel casting industry players toward greener production methods. Energy-efficient furnaces, waste recycling, and reduction of emissions are becoming industry standards. Companies are adopting cleaner raw materials and optimizing processes to minimize environmental impact. For instance, Wear Steels implemented green casting techniques, resulting in up to 30% energy savings, a 25% reduction in grid electricity consumption through renewable energy sources.

Automation in steel casting facilities enhances productivity, quality control, and safety. Robotics and automated handling reduce human error and improve consistency in mold preparation, pouring, and finishing. Advanced sensors and IoT integration enable real-time monitoring of casting processes, minimizing defects and downtime. Automated systems also reduce labor costs and support scalability. As manufacturers seek to meet growing demand efficiently, investments in Industry 4.0 technologies become a major driver.

Digital transformation is reshaping the steel casting market trends with data-driven decision-making and automation. Industry 4.0 tools like AI, machine learning, and digital twins optimize casting design, production, and quality control. Real-time monitoring enables rapid defect detection and process adjustments. In 2022, ExOne introduced the S-Max® Flex, a cost-effective, large-format binder jetting system designed for foundries. These innovations are helping to improve productivity, reduce waste, and enable mass customization.

Aftermarket support, including repair, refurbishment, and maintenance of steel cast components, is gaining importance. Industries prefer vendors offering comprehensive services that extend product life and reduce downtime. Predictive maintenance and condition monitoring using IoT technologies help in proactive service delivery. This trend encourages manufacturers to develop service capabilities alongside production, providing integrated solutions to improve operational efficiency and reduce total cost of ownership.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The EMR’s report titled “Steel Casting Market Report and Forecast 2026-2035” offers a detailed analysis of the market based on the following segments:

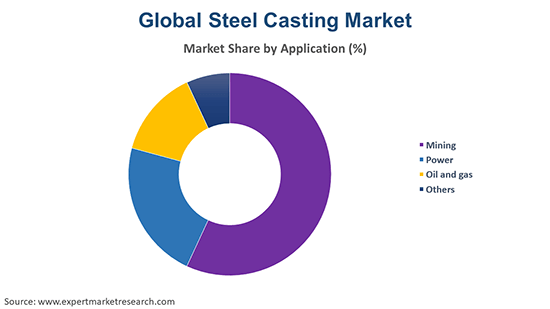

Market Breakup by Application

Key Insight: The mining industry is a leading segment due to its heavy reliance on robust and wear-resistant components. Steel castings are essential in equipment like rock crushers, grinding mills, draglines, and excavators, which operate under extreme conditions. The constant demand for mineral extraction and processing, especially in countries rich in natural resources, ensures steady growth in casting requirements. For instance, in January 2025, Gainwell's mining machines deployed steel castings in breaker bodies, cutter heads, and linings for durability, strength, and wear resistance underground.

Market Breakup by Region

Key Insight: The steel casting market is most dominant in Asia Pacific, fueled by rapid industrialization, mining expansion, and large-scale infrastructure projects, particularly in China and India. China’s massive demand for construction equipment, mining machinery, and infrastructure development has made it the world’s largest consumer of steel castings. For instance, Beijing’s Daxing International airport and high-speed rail expansions require steel-intensive components. Steel cast components are also essential for applications like crushers, excavators, and heavy transport systems, where strength and durability are critical.

Huge Steel Casting Demand in Power & Oil and Gas

The power generation sector holds a significant share of the steel casting market, particularly in thermal, hydro, and nuclear plants. Steel castings are used in turbine housings, valves, boiler components, and pressure vessels due to their strength and heat resistance. In May 2025, AEM Special Steels in Saint Petersburg cast a 205 tonne special alloy steel ingot to be used for the planned small modular reactor in the Jizzakh region of Uzbekistan. In developing countries like India and Vietnam, rising energy demand has spurred infrastructure investments, boosting casting requirements.

The oil and gas sector is another dominant segment in the market. It relies on steel castings for offshore drilling rigs, valves, pumps, blowout preventers, and subsea equipment. These components must resist corrosion, extreme pressure, and temperature fluctuations. As exploration pushes into deeper waters and harsher environments, the demand for highly durable and precise cast components grows. For example, high-alloy steel castings are used in subsea Christmas trees and manifolds to maintain structural integrity under high pressure. Additionally, the expansion of LNG infrastructure in countries like China and Malaysia has further increased the need for corrosion-resistant castings in cryogenic applications.

Thriving Steel Casting Adoption in Europe & North America

Europe holds a significant steel casting market share, particularly in high-precision industrial sectors like automotive, power, and rail. Germany, Italy, and France rely on steel castings for wind turbines, rail systems, and energy infrastructure. In January 2025, Enercon, Salzgitter AG, and TMGROUP cooperated to produce one of Germany’s first lower emissions steel towers for an onshore wind turbine, for the Diepholzer Bruch wind farm in Lower Saxony. Europe is also a hub for sustainable and precision casting, often using advanced technologies. The region’s strong regulatory frameworks and emphasis on low-carbon production also drive innovation in high-quality, durable, and environmentally friendly steel casting solutions.

North America plays an important, role in the global steel casting market. The United States and Canada rely heavily on cast steel parts in defense, oil and gas, and construction equipment. However, market dominance is limited by outsourcing to lower-cost manufacturing regions. Despite this, major players like Wabtec and Bradken operate foundries supplying high-spec castings for rail and mining. Recent infrastructure initiatives have boosted demand for domestic castings in bridges, pipelines, and transport networks. Still, higher production costs and reliance on imports position North America as a less dominant player globally.

Major players in the steel casting market are employing several key strategies to strengthen their market presence, enhance product quality, and meet evolving industry demands. Product innovation remains a core focus, with companies investing in advanced metallurgy, precision casting techniques, and new alloy development to improve strength, corrosion resistance, and performance. Customization is another major strategy, with manufacturers tailoring cast components for specific applications in automotive, construction, energy, and heavy machinery sectors.

Strategic partnerships and mergers help expand global reach and optimize production capabilities. Many firms also focus on capacity expansion and automation to increase efficiency, reduce lead times, and meet growing demand. Sustainability is becoming a priority, prompting investments in cleaner production processes, energy-efficient furnaces, and recycling of scrap metal to lower environmental impact. In response to price volatility and supply chain disruptions, companies are further adopting diversified sourcing strategies and build resilient logistics networks.

Founded in 1953 and headquartered in Portland, the United States, Precision Castparts Corp. is a world leader in complex metal components. A Berkshire Hathaway company since 2016, it excels in aerospace and industrial casting, known for innovations in investment casting, forged products, and high-performance alloys for demanding environments.

Established in 1956 and headquartered in Tokyo, Japan, Hitachi Metals Ltd. is renowned for its high-grade specialty steel and cast products. The company has pioneered innovations in magnetic materials and high-performance castings, serving sectors like automotive, aerospace, and electronics with advanced metallurgy and precision engineering solutions.

Japan Casting & Forging Corp., founded in 2003 and based in Hiroshima, Japan, specializes in large-scale steel castings and forgings. Known for supplying critical components for nuclear, thermal, and hydroelectric power plants, it has built a reputation for delivering high-integrity, custom-engineered cast products under strict quality standards.

Founded in 1905 and headquartered in Kobe, Japan, Kobe Steel Ltd. (Kobelco) is a leading producer of steel and machinery. Its achievements include innovations in low-carbon steel casting and high-strength materials for construction, shipbuilding, and automotive industries, supported by ongoing R&D and a strong global supply network.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

Other players in the steel casting market are Peekay Steel Castings Pvt. Ltd., amongst others.

Explore the future of manufacturing with our steel casting market trends 2026 report. Get free access to expert forecasts, emerging technologies, and growth strategies shaping the industry. Download your sample report now to gain a competitive edge and make informed decisions in this evolving and vital global market.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

The market is projected to grow at a CAGR of 5.50% between 2026 and 2035.

Key strategies driving the market include investment in advanced casting technologies, expansion into emerging markets, and product customization for end-use industries. Companies focus on sustainability, digital integration, and strategic partnerships to improve efficiency, reduce costs, and meet growing demand in automotive, construction, energy, and heavy machinery sectors.

The introduction of automation in the die-casting method is expected to be a key trend guiding the growth of the market.

The major regions in the market are North America, Latin America, the Middle East and Africa, Europe, and the Asia Pacific.

Steel casting finds applications in mining, power, and oil and gas, among others.

The key players in the market report include Precision Castparts Corp. (Berkshire Hathaway Inc.), Hitachi Metals Ltd., Japan Casting & Forging Corp., Kobe Steel Ltd., and Peekay Steel Castings Pvt. Ltd., amongst others.

In 2025, the market reached an approximate value of USD 35.29 Billion.

Asia Pacific dominates the market, driven by rapid industrialization, mining expansion, and large-scale infrastructure projects.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2025 |

| Historical Period | 2019-2025 |

| Forecast Period | 2026-2035 |

| Scope of the Report |

Historical and Forecast Trends, Industry Drivers and Constraints, Historical and Forecast Market Analysis by Segment:

|

| Breakup by Application |

|

| Breakup by Region |

|

| Market Dynamics |

|

| Competitive Landscape |

|

| Companies Covered |

|

| Report Price and Purchase Option | Explore our purchase options that are best suited to your resources and industry needs. |

| Delivery Format | Delivered as an attached PDF and Excel through email, with an option of receiving an editable PPT, according to the purchase option. |

Datasheet

One User

USD 2,499

USD 2,249

tax inclusive*

Single User License

One User

USD 3,999

USD 3,599

tax inclusive*

Five User License

Five User

USD 4,999

USD 4,249

tax inclusive*

Corporate License

Unlimited Users

USD 5,999

USD 5,099

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share