Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

Trending Now

The global scrap metal shredder market is expected to grow at a CAGR of 2.00% in the forecast period of 2025-2034.

Base Year

Historical Period

Forecast Period

In 2021, over 250 metal recycling facilities in the U.S. were operating with shredders.

The United States imported 5.262 million tons of steel scrap in 2021, with a 17.1% increase from 2020.

As per industry reports, the United States recycles approximately 150 million metric tonnes of scrap metal each year.

Value in USD Million

2025-2034

Scrap Metal Shredder Market Outlook

*this image is indicative*

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

| Global Scrap Metal Shredder Market Report Summary | Description | Value |

| Base Year | USD Million | 2024 |

| Historical Period | USD Million | 2018-2024 |

| Forecast Period | USD Million | 2025-2034 |

| Market Size 2024 | USD Million | XX |

| Market Size 2034 | USD Million | XX |

| CAGR 2018-2024 | Percentage | XX% |

| CAGR 2025-2034 | Percentage | 2.00% |

| CAGR 2025-2034 - Market by Region | Asia Pacific | 2.6% |

| CAGR 2025-2034 - Market by Country | India | 3.0% |

| CAGR 2025-2034 - Market by Country | China | 2.5% |

| CAGR 2025-2034 - Market by Design | Low-Speed High-Torque Shredder | 2.2% |

| CAGR 2025-2034 - Market by Application | E-Scrap | 3.1% |

| Market Share by Country 2024 | Japan | 5.7% |

Scrap metal shredder is a kind of machine used for shredding the waste metal and reducing its volume to convert it into small and reusable pieces. These metal shredders are available in different capacities to produce required output sizes for processing various metals. The blades of the machine are made from special steel to enhance its life expectancy and reduce its maintenance cost on such parts.

The rising industrialisation activities in developing countries have supported scrap metal shredder market expansion. For instance, the Indian government's "Make in India" initiative has led to a significant increase in industrial activities, resulting in a substantial amount of scrap metal generation. Additionally, the increasing demand for recovering metal from slag residue and the need for environmentally friendly scrap recycling processes are driving the market.

Introduction of electric shredders, rise of steel prices, and increasing demand for shredders in automotive industries are key trends augmenting the scrap metal shredder market growth

Government's efforts to promote sustainable practices and reduce pollution are creating opportunities for manufacturers in scrap metal shredder market. The European Union's Circular Economy Package aims to reduce waste and increase recycling rates, which can drive the demand for scrap metal shredders.

Scrap metal shredder manufacturers are focusing on technological advancements to enhance efficiency and reduce costs. This includes the development of electric shredders, which are more environmentally friendly and offer lower operating costs.

The growth is also fuelled by the focus of manufacturers on acquiring producers of recycled metal goods and the implementation of new tariffs that positively impact the scrap metal shredder market outlook. For instance, the United States' tariffs on imported steel have led to an increase in domestic scrap metal recycling.

Scrap metal shredders are the key equipment for manufacturers engaged in the recycling of metals, automotive, and steel manufacturing industries. The high prices of metal are pushing the companies to be more efficient and invest in machinery like scrap metal shredders.

In the EU, recycling scrap metals saves around 200 million tonnes of CO2 emissions annually, which has prompted the government to implement regulations to encourage metal recycling. This is driving steel mills to invest in scrap metal shredding equipment to increase their use of recycled materials. In the coming years, the implementation of new tariffs and regulations by governments to clean up heavy manufacturing industries is expected to further aid in scrap metal shredder market development.

Moreover, there is an increasing demand for scrap metal recycling to conserve natural resources and reduce the environmental impact of mining. Scrap metal shredders are crucial equipment for efficiently recycling scrap metals from various sources like automobiles, e-waste, and heavy industrial scrap. As per industry reports, recycling 1 tonne of scrap steel saves 2,500 lbs of iron ore, 1,400 lbs of coal, and 120 lbs of limestone.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The EMR’s report titled “Scrap Metal Shredder Market Report and Forecast 2025-2034” offers a detailed analysis of the market based on the following segments:

Market Breakup by Type

Market Breakup by Design

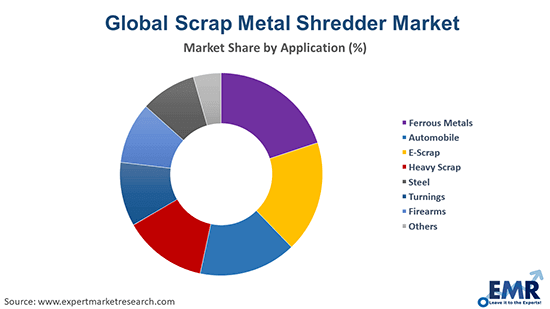

Market Breakup by Application

Market Breakup by Region

| CAGR 2025-2034 - Market by | Design |

| Low-Speed High-Torque Shredder | 2.2% |

| Single-Shafted Shredder | 2.1% |

| Pre-Shredder | XX% |

| Others | XX% |

| CAGR 2025-2034 - Market by | Application |

| E-Scrap | 3.1% |

| Ferrous Metals | 2.3% |

| Steel | 1.8% |

| Firearms | 2.1% |

| Automobile | XX% |

| Heavy Scrap | XX% |

| Turnings | XX% |

| CAGR 2025-2034 - Market by | Region |

| Asia Pacific | 2.6% |

| Middle East and Africa | 2.2% |

| Latin America | 1.9% |

| North America | 1.6% |

| Europe | 1.5% |

| CAGR 2025-2034 - Market by | Country |

| India | 3.0% |

| China | 2.5% |

| Australia | 1.8% |

| UK | 1.6% |

| USA | 1.5% |

| Canada | XX% |

| Germany | XX% |

| France | XX% |

| Italy | 1.3% |

| Japan | XX% |

| Saudi Arabia | XX% |

| Brazil | XX% |

| Mexico | XX% |

Diesel scrap metal shredders leads due to their extensive use in many industries

Diesel scrap metal shredders are powered by diesel engines and are commonly used in industrial settings due to their high power output and durability. On the other hand, electric scrap metal shredders are powered by electricity and are becoming increasingly popular due to their lower emissions and quieter operation.

| 2024 Market Share by | Country |

| Japan | 5.7% |

| USA | XX% |

| Canada | XX% |

| UK | XX% |

As per scrap metal shredder market analysis, diesel scrap metal shredders currently dominate the market share due to their widespread use in steel manufacturing and automotive recycling. However, the market for electric scrap metal shredders is expected to grow at a faster rate in the coming years due to increasing environmental regulations and emission standards that are restricting the use of diesel-powered equipment.

Ferrous metals hold a significant market share due to rising demand for recycled steel and iron

Ferrous metals are the most recycled materials and are among the simplest to recycle because they can be magnetically separated from trash. The demand for ferrous metal shredders is driven by the need to recycle steel and iron, which are essential components in various industries such as construction, automotive, and manufacturing.

The automobile segment is also significant in scrap metal shredder market report. The demand for automobile shredders is driven by the need to recycle end-of-life vehicles (ELVs). Automobile shredders are designed to handle the complex and diverse materials found in vehicles, such as plastics, glass, and metal.

E-scrap, or electronic waste, is a growing segment and the demand for e-scrap shredders is driven by the increasing need to recycle electronic components such as circuit boards, wires, and other electronic materials. E-scrap shredders are designed to handle the complex and hazardous materials found in electronic waste.

North American market to remain the largest, while the Asia Pacific market is expected to grow at a faster rate due to rapid economic development.

North America is expected to be the largest market for scrap metal shredders due to its strong industrial and building activity, environmental sustainability measures, and regional metal demand. The region is home to major steel mills and automotive manufacturing facilities, which require significant amounts of scrap metal for their operations. The demand for scrap metal shredders in North America is further driven by the need to recycle metal waste efficiently.

The Asia Pacific region is expected to have the second-largest scrap metal shredder market share, driven by supportive government policies for waste management and environmental protection and rising economic development. The region is home to major factories and manufacturing facilities, which generate significant amounts of scrap metal waste.

Market players are focused on expanding their manufacturing facilities, R&D investments, and infrastructural developments to maintain their competitiveness

Granutech-Saturn Systems was founded in 1971 and is headquartered in Dallas, Texas. It offers industrial equipment, including shredders, hammermills, crushers, loggers, grinders, granulators, refiner mills, and mobile auto crushers. The company also provides equipment installation, repair, spare parts, on-site support, and technical support services.

Komar Industries, Inc. was founded in 1977 and is headquartered in Ohio, United States. It specialises in the design and manufacturing of waste handling equipment and industrial waste and recycling processing systems. It also offers installation and maintenance support.

Forrec srl was founded in 2007 and is based in Italy, Europe. The company produces machines and customised solutions for the recycling of urban and industrial waste. Their products include shredding systems, grinders, and granulators. It also provides services related to waste treatment.

SSI Shredding Systems, Inc. was founded in 1980 and is headquartered in Oregon, United States. It is a trusted provider of high-quality shredding solutions and reliable support services. Its product line includes industrial shredders, primary reducers, transfer station compactors, and balers capable of processing tires, wood, and industrial waste.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

Other key players in the global scrap metal shredder market include Williams Patent Crusher and Pulverizer Co., Inc. and Fornax Technology Pvt Ltd, among others.

Scrap Metal Shredder Market Size

Scrap Metal Shredder Market Growth

Scrap Metal Shredder Market Trends

Scrap Metal Shredder Market Share

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

The scrap metal shredder market is expected to grow at a CAGR of 2.00% between 2025 and 2034.

The major drivers of the market include the increasing recycling of metal, the high prices of metal, and the introduction of favourable government initiatives aimed at boosting the judicious utilisation of resources.

The growing environmental concerns, rapid industrialisation, the growing adoption of sustainable development plans, the increasing investments in scrap metal shredders by steel mills, and the rising demand for recycled metal in sectors like automotive and construction are the key trends guiding the market growth.

Regions considered in the market are North America, Europe, the Asia Pacific, Latin America, and the Middle East and Africa.

The leading types of scrap metal shredders in the market are diesel and electric.

The main scrap metal shredder designs in the market are low-speed high-torque shredder, pre-shredder, and single-shafted shredder, among others.

The significant applications of scrap metal shredder are ferrous metals, automobile, e-scrap, heavy scrap, steel, turnings, and firearms, among others.

Key players in the market are Granutech-Saturn Systems, Komar Industries, Inc, Forrec srl, Williams Patent Crusher and Pulverizer Co., Inc., SSI Shredding Systems, Inc., and Fornax Technology Pvt Ltd, among others.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2024 |

| Historical Period | 2018-2024 |

| Forecast Period | 2025-2034 |

| Scope of the Report |

Historical and Forecast Trends, Industry Drivers and Constraints, Historical and Forecast Market Analysis by Segment:

|

| Breakup by Type |

|

| Breakup by Design |

|

| Breakup by Application |

|

| Breakup by Region |

|

| Market Dynamics |

|

| Competitive Landscape |

|

| Companies Covered |

|

| Report Price and Purchase Option | Explore our purchase options that are best suited to your resources and industry needs. |

| Delivery Format | Delivered as an attached PDF and Excel through email, with an option of receiving an editable PPT, according to the purchase option. |

Datasheet

One User

USD 2,499

USD 2,249

tax inclusive*

Single User License

One User

USD 3,999

USD 3,599

tax inclusive*

Five User License

Five User

USD 4,999

USD 4,249

tax inclusive*

Corporate License

Unlimited Users

USD 5,999

USD 5,099

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Our step-by-step guide will help you select, purchase, and access your reports swiftly, ensuring you get the information that drives your decisions, right when you need it.

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City,1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

United States

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

United States (Head Office)

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City, 1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

Share