Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The global robotic welding market size reached nearly USD 4861.19 Million in 2025. The market is projected to grow at a CAGR of 8.00% between 2026 and 2035 around USD 10494.94 Million by 2035.

Base Year

Historical Period

Forecast Period

The shortage of skilled welders, in countries, such as the UK, Germany, the USA, etc. is compelling automotive and electronics manufacturers to invest in robotic welding.

Fanuc Corporation, Yaskawa Electric Corporation, and Kuka AG are a few of the major companies in the market.

The global robotic welding market is driven by the increasing adoption of Industry 4.0.

Compound Annual Growth Rate

8%

Value in USD Million

2026-2035

*this image is indicative*

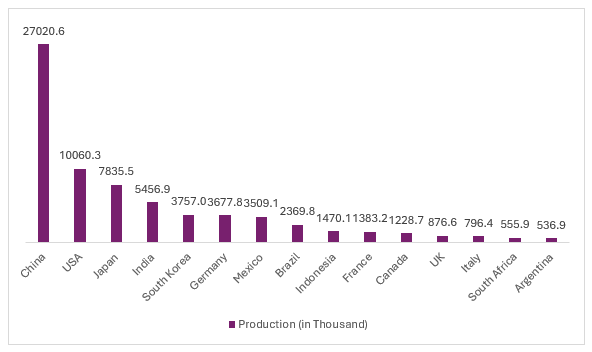

The rising industrialisation and surging manufacturing activities are supporting the demand for robotic welding from several end-use sectors, such as automotive, fabrication, electronics, and aerospace. About 3% of the global GDP is contributed by the automobile sector, with rising nations like China and India having the highest percentage at 7%. In the automotive sector, large robots conduct spot welding on heavy car body panels owing to their long arms and high payload capabilities.

Figure: Automotive Production in Leading Economies, 2022

Some of the factors driving the robotic welding market growth are the integration of advanced technologies and the ongoing shortage of welders, which is straining the manufacturing processes. The integration of advanced technology like artificial intelligence (AI) and the Internet of things (IoT) boosts the productivity and accuracy of these robots. Robotic welding cells with IoT connectivity inform operators when maintenance is required, allowing timely repairs, and reducing expensive downtime.

Rapid industrialisation; rising demand for personal mobility solutions; integration of advanced technologies; and the robustly growing military and logistics sectors are aiding the robotic welding market growth

Rapid industrialisation and the robustly growing manufacturing sector support the demand for robotic welding from several end-use sectors, such as the automotive, fabrication, electronics, and aerospace.

Artificial intelligence (AI) and the Internet of things (IoT) boost the productivity and accuracy of robots while improving weld quality and enabling real-time analysis.

The rising demand for vehicles is prompting manufacturers to increase their production. Since welding robots can perform welding continuously while providing reliable and durable welds, their demand is rising in the automotive sector.

Robotic welding provides safety against flashes, fumes, sparks, and heat produced from welding, which is hazardous to human health.

Shipbuilders are increasing investments in robotic welding technology to cater to rising demand from the commercial, logistics, and military sectors.

The market is being driven by the increasing adoption of Industry 4.0. The initiative calls for the digitisation of the manufacturing sector by the adoption of trends such as data and connectivity, analytics, human-machine interaction, and improvements in robotics. Welding plays a pivotal role in automotive production to join metal car parts, such as the body, chassis, and car panels, among others. This drives the deployment of robotic welding that helps in precise and mass production. Approximately 60 million vehicles are manufactured worldwide annually.

Furthermore, by enhancing the energy efficiency of welding robots, manufacturers can help end users perform green manufacturing. Electrical and electronics manufacturing often involves intricate components and connections. Robotic welding ensures precise and consistent welds, critical for maintaining product quality and reliability. These robots can achieve accuracy levels difficult to match with manual welding. The electronics manufacturing sector plays a vital role in the U.S. economy, accounting for 1.6% of GDP.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

"Global Robotic Welding Market Report and Forecast 2026-2035" offers a detailed analysis of the market based on the following segments:

Market Breakup By Type

Market Breakup By Payload

Market Breakup By End User

Market Breakup By Region

Spot welding robots are expected to hold significant market share as they are widely adopted by the automotive industry

Spot welding robots dominate the robotic welding market share as they are used to manufacture car parts cost-efficiently, reliably, and quickly. Robots efficiently perform spot welding and add automation to the welding process.

Their dexterity helps them reach the workpiece from any orientation, which is crucial to orient the tool to the exact location where the welding needs to be performed. Spot welding using articulated robots finds use in automobile manufacturing to weld components, such as car chassis.

Arc welding robots featuring a slimmer profile and internalised cabling result in more efficient and optimised welding. Gas tungsten arc welding (GTAW) is a common application of robotic arc welding. Robotic GTAW is a precision welding method to weld thin metals and produce detailed and clean welds.

Major market players are increasing their collaboration, partnership, and research and development activities to gain a competitive edge

Fanuc Corporation is headquartered in Japan and founded in 1956. The company provides a diverse portfolio of welding and cutting solutions, available under the well-established brands of FANUC Robot ARC Mate, FANUC Robot M, and FANUC Robot R.

ABB Ltd., headquartered in Switzerland and founded in 1988, offers diverse robot models, such as the robust IRB 7600 with a hefty 630 Kg handling capacity, ideal for heavy-duty tasks.

Yaskawa Electric Corporation, headquartered in Japan and founded in 1915, offers AR-Series welding robot models, HC10 series welding cobot, and HC20 series welding cobot.

KUKA AG, headquartered in Germany and founded in 1898, offers specialised ARC welding solutions through its KUKA arc welding robots. These robots come with payload capacities ranging from 6 to 22 kg and offer impressive reaches of up to 3,100 mm.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

Other key players in the robotic welding market include EVS TECH CO., LTD, Estun Automation Co., Ltd., NACHI-FUJIKOSHI CORP., and Panasonic Corporation.

The Asia Pacific is anticipated to hold a dominant position in the robotic welding market in the forecast period. According to industry reports, Asia continues to maintain its position as the globe's most extensive industrial robot market, with 73% of all new robots being installed in the region in 2021. Countries like Japan, China and India are significant automotive producers globally. Under the Chinese government’s 14th Five-Year Plan, the government identifies industrial robots as crucial to the country’s economy and announced that China will play a key role in global robotics innovation by 2025.

The Europe robotic welding market is being driven by the expansion of the automotive sector. The automotive sector is crucial for the European economy and contributes around 7% to its GDP. In the automotive sector, high-tech robotic welding systems are used to develop new parts, such as chassis as well as for automotive component repair. According to the International Federation of Robotics (IFR) report ‘World Robotics 2022’, the German industries with the highest volumes of industrial robots include automotive with 49% and metal with 13%. Further, welding is included among the most popular applications of new industrial robots in these industries.

North America also holds a significant share of the robotic welding market and is driven by the rapid adoption of industrial automation. According to the National Automobile Dealers Association (NADA), the North American automotive sector produces around 17 million vehicles annually. As a result, the sector supports the use of robotic welding for spot and arc welding. According to the American Welding Society, the welding sector in the USA is expected to face a shortage of about 360,000 welders by 2027. This creates an opportunity for the integration of robotic welding systems.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

In 2025, the market value was approximately USD 4861.19 Million.

The market is projected to grow at a CAGR of 8.00% between 2026 and 2035.

The market is estimated to witness a healthy growth in the forecast period of 2026-2035 to reach USD 10494.94 Million by 2035.

The major drivers include rising industrialisation and manufacturing activities, rising need for mobility solutions, and rising investments from the logistics and military sectors.

The key trends aiding the market include the integration of advanced technologies in robotic welding systems, increasing adoption of Industry 4.0, and improvements in the energy efficiency of welding robots.

The different types of welding robots include spot welding robots and arc welding robots, among others.

The major applications of robotic welding include automotive and transportation, electrical and electronics, metals and machinery, and aerospace and defence, among others.

The major players in the market include Fanuc Corporation, ABB Ltd., Yaskawa Electric Corporation, Kuka AG, EVS TECH CO., LTD, Estun Automation Co., Ltd., NACHI-FUJIKOSHI CORP., and Panasonic Corporation.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2025 |

| Historical Period | 2019-2025 |

| Forecast Period | 2026-2035 |

| Scope of the Report |

Historical and Forecast Trends, Industry Drivers and Constraints, Historical and Forecast Market Analysis by Segment:

|

| Breakup by Type |

|

| Breakup by Payload |

|

| Breakup by End User |

|

| Breakup by Region |

|

| Market Dynamics |

|

| Competitive Landscape |

|

| Companies Covered |

|

Single User License

One User

USD 3,999

USD 3,599

tax inclusive*

Datasheet

One User

USD 2,499

USD 2,249

tax inclusive*

Five User License

Five User

USD 4,999

USD 4,249

tax inclusive*

Corporate License

Unlimited Users

USD 5,999

USD 5,099

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share