Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

Trending Now

The global industrial mixers market value reached around USD 2.65 Billion in 2024. Sectors such as food and beverage, pharmaceuticals, and chemicals rely heavily on industrial mixers for consistent product quality and operational efficiency. As these industries expand, the need for advanced mixing solutions becomes important, contributing to market growth. Stricter health and safety regulations in the food and pharmaceutical sectors also necessitate high-sanitisation mixers. As a result, the industry is expected to grow at a CAGR of 5.20% during the forecast period of 2025-2034 to attain a value of USD 4.40 Billion by 2034. Innovations in automation and smart mixing systems are making industrial mixers more appealing to manufacturers.

Base Year

Historical Year

Forecast Year

Value in USD Billion

2025-2034

Industrial Mixers Market Outlook

*this image is indicative*

| Global Industrial Mixers Market Report Summary | Description | Value |

| Base Year | USD Billion | 2023 |

| Historical Period | USD Billion | 2018-2024 |

| Forecast Period | USD Billion | 2025-2034 |

| Market Size 2024 | USD Billion | 2.65 |

| Market Size 2034 | USD Billion | 4.4 |

| CAGR 2018-2024 | Percentage | XX% |

| CAGR 2025-2034 | Percentage | 5.2% |

| CAGR 2025-2034 - Market by Region | Asia Pacific | 6.7% |

| CAGR 2025-2034 - Market by Country | India | 7.1% |

| CAGR 2025-2034 - Market by Country | Brazil | 5.7% |

| CAGR 2025-2034 - Market by Type | Liquid-Liquid | 5.5% |

| CAGR 2025-2034 - Market by End Use | Pharmaceuticals | 5.6% |

| Market Share by Country 2023 | Saudi Arabia | 0.8% |

Industrial mixers are used for various applications in manufacturing industries to mix two or more distinct materials to generate a homogenous product. For instance, coal ash and cement are mixed in a precise ratio to produce pozzocrete cement. Industrial mixers help manufacturers to achieve desired weight/volume with accurate particle sizing and allows the enhancement of colour, texture, and other essential characteristics of the final product.

The growing demand for high-performance mixing devices to enhance manufacturing performance is aiding the industry's growth. This is being supported by the increasing demand for energy-efficient devices and the growing focus on flow maximisation, rapid mixing and high processing speed, lower power consumption, and equipment flexibility. Moreover, the increasing utilisation of industrial mixers by small and medium-sized manufacturers, owing to their low operating cost, advancements in design technology, and increasing government support for advanced technology, is significantly contributing to the growth of the industrial mixers market.

Over the forecast period, the growing adoption of automation in industries to reduce error rates and provide consistent quality is expected to drive the demand for PLC-based mixers. The use of PLCs in industrial mixers will allow the manufacturers to monitor the entire process and minimise variations to achieve batch-to-batch consistency.

Rising demand for energy-efficient devices, adoption of industry 4.0, and increased emphasis on cleanliness in the food and beverage industries are the key trends propelling the market growth.

The eco-friendly mixers are gaining prominence in the market due to the growing awareness regarding environmental concerns. Innovations in mixers are aimed at reducing energy usage while maintaining the performance standards. Some of these innovations include computational fluid dynamics (CFD) simulation, variable speed drives and optimised impeller designs that can boost aid the industrial mixers demand. The Energy Efficiency Directive (EU) emphasises the importance of energy efficiency and conservation across multiple sectors, including the food and beverage manufacturing industry. It promotes the use of renewable energy sources, the reduction of greenhouse gas emissions, and the implementation of advanced technologies for improved efficiency. Countries that have signed the Paris Agreement are also required to reduce carbon emissions. Many food and beverage companies are modifying their operations to meet these goals by reducing greenhouse gas emissions and adopting carbon-neutral practices. Furthermore, regions such as Canada and the European Union have introduced carbon taxes or cap-and-trade systems that impact the food and beverage sector, leading to the adoption of more sustainable practices, which boosts the demand of energy-efficient mixers.

Manufacturers are readily relying on automation to develop intelligent mixing solutions that can enhance industrial mixers market value. They are relying on sensors and data analytics for fine-tuning the mixing parameters to offer consistent product quality with minimal human error and low energy. Several market players are launching smart industrial mixers to gain competitive edge over other players. For instance, in 2023 GEA Group launched a new range of smart mixers designed for the food and beverage sector, with advanced IoT capabilities. These mixers allow for real-time performance monitoring, which boosts productivity and reduces waste. Similarly, SPX FLOW has upgraded its Lightnin Series mixers to include IoT-enabled sensors for remote monitoring and improved energy efficiency. This new feature provides users with real-time data insights, helping them optimise processes and lower energy consumption. Additionally, Alfa Laval launched IoT-driven industrial mixers, specifically for the chemical and pharmaceutical sectors, in 2023, allowing users to oversee and optimise mixing parameters with the aid of the centralised system, and offers energy savings of up to 30%.

The adoption of Variable Frequency Drive (VFD)-enabled mixers is gaining momentum in the industrial mixers market due to their ability to enhance energy efficiency and operational performance. VFDs allow for precise control of motor speed and torque, enabling mixers to adjust their operation according to specific process requirements. This capability not only reduces energy consumption but also reduces wear and tear on equipment, leading to lower maintenance costs and extended equipment lifespan. As industries increasingly focus on cost reduction, the integration of VFD technology in mixing processes becomes essential. The growing demand for energy-efficient solutions across various sectors, including food processing, pharmaceuticals, and chemicals, is driving the widespread implementation of VFD-enabled mixers. Furthermore, advancements in VFD technology, such as real-time monitoring and predictive maintenance capabilities, are expected to further enhance their appeal in the market by improving operational efficiency and reducing downtime.

The increasing prominence of ultra-high-shear mixers reflects a significant trend within the industrial mixers market, driven by the need for superior mixing performance and product quality. These mixers are designed to produce intense shear forces that can effectively blend materials with varying viscosities and particle sizes. Their ability to create homogeneous mixtures rapidly makes them particularly valuable in industries such as cosmetics, pharmaceuticals, and food processing, where consistency and quality are paramount. Additionally, ultra-high-shear mixers facilitate the dispersion of difficult-to-mix ingredients, such as powders in liquids or emulsions, which is critical for developing innovative products. As manufacturers strive to meet stringent quality standards and consumer demands for high-performance products, the adoption of ultra-high-shear mixers is expected to rise.

There is an increased emphasis on cleanliness in the food and beverages as well as the pharmaceuticals sector and recent developments in the market are aimed at simplifying the maintenance of the equipment to prevent contamination and contributing to the demand of industrial mixers market. Stringent regulations and standards can also enhance the demand for cleanliness in these sectors. For instance, the FDA's Food Safety Modernization Act (FSMA) aims to prevent contamination in the food supply chain by establishing stringent cleanliness standards, requiring food facilities to adopt comprehensive prevention-focused measures throughout the supply chain. Furthermore, the act requires regular cleaning and sanitisation of surfaces, equipment and utensils, among others, that encounter food to reduce the risk of contamination.

Increased breakthroughs in material science have further led to the development of resilient and corrosion-resistant components in mixing equipment. For instance, novel materials can enhance the lifespan of mixers and agitators and reduce overall maintenance costs and downtime.

One of the primary challenges faced by manufacturers is the increased cost of the installation and maintenance of industrial mixers. These machines can be quite costly, particularly the ones which are designed for specialised functions such as high shear mixing as well as submersible applications. Furthermore, the ongoing demand for repairs and maintenance due to wear and tear contributes significantly to the operational expenses of the manufacturers.

Additionally, the fluctuating and unpredictable prices of raw materials such as stainless steel and various metals, used in the production of industrial mixers can also pose a significant challenge for industrial mixers demand forecast. For instance, Stainless steel is mainly manufactured using 80%-90% scrap material and around 10% Class 1 nickel, with prices of both expected to rise along with the energy costs. The instability in commodity prices also has a direct impact on the profit margins of manufacturers.

There is a rising demand for industrial mixers that can address the specific needs of different industry verticals. Manufacturers are increasingly investing in mixing equipment which offers great flexibility for usage in different end-use sectors. Major companies such as MIXACO and UTG Mixing Group are offering fully customisable industrial mixers which can meet different process needs and contribute to the industrial mixers market revenue. For instance, these mixers offer the flexibility for regular recipe modifications and incorporate user-friendly cleaning features, which are important for sectors such as food processing, chemicals, and pharmaceuticals. The CM i4 fleX mixer from MIXACO is suitable for different container sizes and is gaining popularity in businesses which may require frequent changes in their production workflows.

Volumetric mixers are also become more popular in the construction sector in recent years as they offer versatility and the capability to produce concrete as needed. These mixers allow companies to prepare customised concrete mixtures at the job site itself, reducing waste and lowering labour costs.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

“Industrial Mixers Market Report and Forecast 2025-2034” offers a detailed analysis of the market based on the following segments:

Based on technology, the market is divided into:

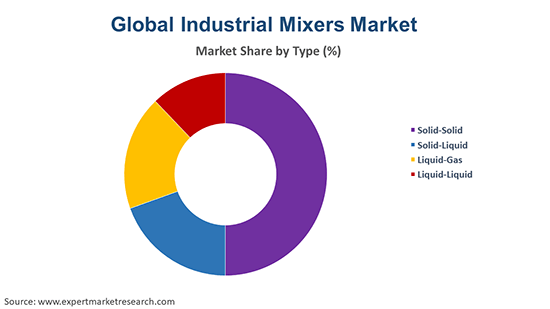

The various types of industrial mixers in industrial mixers market include:

Based on end use, the industrial mixers market can be segmented into:

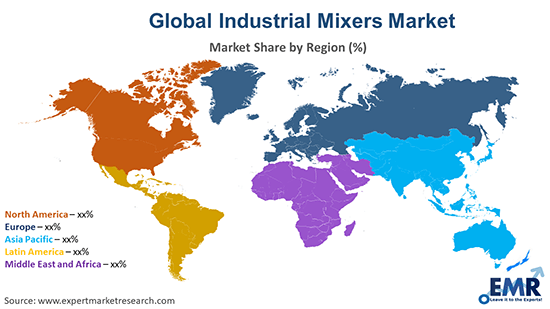

Based on region, the industrial mixers market is divided into:

| CAGR 2025-2034 - Market by | Type |

| Liquid-Liquid | 5.5% |

| Liquid-Gas | 4.7% |

| Solid-Solid | XX% |

| Solid-Liquid | XX% |

| CAGR 2025-2034 - Market by | End Use |

| Pharmaceuticals | 5.6% |

| Plastic Industry | 4.7% |

| Food and Beverages | XX% |

| Mineral Industry | XX% |

| Chemicals | XX% |

| Others | XX% |

| CAGR 2025-2034 - Market by | Region |

| Asia Pacific | 6.7% |

| Europe | 4.0% |

| North America | XX% |

| Latin America | XX% |

| Middle East and Africa | XX% |

Market Analysis by Technology

Ribbon mixers occupy a major industrial mixers market share due to their growing use in the handling of bulk solids such as powders, granules, and pellets, among others, in end-use sectors such as food production and pharmaceuticals. Their ability to efficiently mix large volumes makes them perfect for solutions that demand thorough blending of bulk materials with similar particle sizes and densities.

By technology, the market includes other categories such as agitators, which mix liquids or slurries to promote uniformity; paddle mixers, which use flat blades to blend solids and liquids gently, commonly found in the food and pharmaceutical industries; static mixers, which consist of fixed elements that create turbulence for thorough mixing without moving parts, often used in chemical processing; emulsifiers, specialised for combining immiscible liquids like oil and water to create stable emulsions, essential in food production; drum mixers, designed for mixing bulk materials in large containers, commonly used in construction and manufacturing; and homogenizers, which reduce particle size and create uniform mixtures by applying high pressure, widely used in dairy production and pharmaceuticals.

Market Analysis by Type

Liquid-liquid accounts for a significant share of the market and is expected to grow at a CAGR of 5.5%. Liquid-liquid mixers are widely used in the processes of emulsion formation and phase separation that can boost the industrial mixers market demand growth. They are also used in oil refineries as they are essential for removing impurities and the blending of fuels. Additionally, they are finding rising usage in the production of sauces, dressings, and beverages, which require uniformity.

| 2023 Market Share by | Country |

| Saudi Arabia | 0.8% |

| USA | XX% |

| Canada | XX% |

By type of industrial mixer, the market also categorises into solid-solid mixers for blending dry powders or granules, crucial in pharmaceuticals and food processing; solid-liquid mixers, which combine solids with liquids to create suspensions or slurries, commonly used in wastewater treatment and chemical processing; and liquid-gas mixers, facilitating the interaction between liquids and gases, often employed in aeration processes or carbonation in beverages.

Market Analysis by End Use

Based on end use sectors, the chemical industry significantly contributes to the growth of the market. Within the chemical industry, these mixers are used for a wide range of applications, including the blending of solid and liquid and precise mixing to produce speciality chemicals, fertilisers, and different types of rubber compounds, among others.

In the food and beverage sector, industrial mixers are used in the preparation of a variety of products like cake mixes, spices, and functional ingredients, which can boost industrial mixers market expansion. The pharmaceutical sector is expected to witness a CAGR of 5.6% in the forecast period as they are used to blend active or functional ingredients of a drug with recipients such as cellulose, lactose, and starch. Over the forecast period, the product is expected to witness an increased demand for wastewater treatment, which will aid the industry growth.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

North America Industrial Mixers Market Drivers

North America boosts the growth of the industrial mixers industry due to its advanced manufacturing sector, particularly in the pharmaceuticals and food and beverage sectors. In 2022, the manufacturing sector contributed around USD 2.3 trillion to the GDP, which accounted for around 11.4% of the country’s GDP. Industrial mixers are also essential for ensuring compliance with sanitary standards in these sectors and benefit greatly from significant investments in automated mixing technologies with the manufacturing sector being one of the top investors in automation technology in the region.

| CAGR 2025-2034 - Market by | Country |

| India | 7.1% |

| Brazil | 5.7% |

| Saudi Arabia | 5.2% |

| Australia | 5.0% |

| Canada | 4.9% |

| USA | XX% |

| UK | XX% |

| Germany | XX% |

| France | 4.5% |

| Italy | XX% |

| China | XX% |

| Japan | XX% |

| Mexico | XX% |

Asia Pacific Industrial Mixers Market Growth

Region-wise, the Asia Pacific is expected to be one of the leading markets for industrial mixers in the forecast period owing to the rapid urbanisation and industrialisation in the region. India and Australia are expected to grow at a CAGR of 7.1% and 5% respectively in the forecast period due to the rising chemical and pharmaceutical sectors, offering lucrative industrial mixers market opportunities. The regional market is driven by rapid industrialisation and increasing demand for speciality chemicals. Increased production and export activities within the chemical sector further boost the regional market growth.

Europe Industrial Mixers Market Dynamics

The European region is expected to grow at a CAGR of 4.0% with countries like the UK and Germany leading the market share. Germany is increasing the industrial mixers industry revenue as it is known as a prominent industrial area in the region. The expansion of industrial sectors such as chemicals, pharmaceuticals, and wastewater management, among others, boosts the market growth. There is also a rising demand for PLC-based control systems for industrial mixers which can improve efficiency and product quality.

Latin America Industrial Mixers Market Trends

The rising demand from emerging nations such as Brazil and Mexico is fuelling the growth of the regional industry. The expansion of the various end-use sectors like pharmaceuticals, chemicals, and food and beverages is also aiding the industrial mixers market development. Increased investments in energy and mining industries as well as wastewater management are also contributing to the market share. As per the industry reports, in 2022, Latin America and the Caribbean region produced around 8 million barrels of oil per day and constituted around 15% of the world's oil and gas reserves, indicating a positive trend in the energy sector.

Several startups are investing in the trend of sustainability by developing mixers which minimise waste, energy consumption, and environmental effects. They are also developing hybrid mixers which contain features from various mixer types and are known for their adaptability and energy efficiency. Numerous startups are establishing partnership with academic institutions or technology firms to enhance research and development initiatives. As per the industrial mixers market dynamics and trends, partnerships focused on developing innovative materials and designs for more efficient mixing processes are significant in the market.

Admix Inc.

The company has over 30 years of experience but its focus on innovative strategies and startup-like approach has established its position as startup in the industrial mixing sector. The company offers its services to the food, beverage, pharmaceutical, and chemical sectors and is especially known for its high shear mixing technology. It is also focused on research and development along with focus on customised mixing solutions.

Silverson Machines Ltd.

Silverson Machines also have a rich industry heritage, but they have a startup-like focus on innovation and readily launch new products and solutions for high-shear mixing applications. Their products are widely used in biotechnology, cosmetics, pharmaceuticals, and chemicals, among other sectors.

The report gives a detailed analysis of the following key players in the global industrial mixers market, covering their competitive landscape, capacity, and latest developments like mergers, acquisitions, and investments, expansions of capacity, and plant turnarounds. As per the industrial mixers industry analysis, many companies in market are integrating IoT and automation technologies into their mixing equipment to improve process management and data monitoring. They offer smart mixers which are equipped with sensors for real-time performance tracking, enabling predictive maintenance and improving operational efficiency.

Established in 1933, the company has emerged as a prominent leader in industrial mixing technology. The company focuses on offering innovative solutions for mixing, blending, and processing in various sectors such as pharmaceuticals, chemicals, cosmetics, and food production.

Philadelphia Mixing Solutions, Ltd., a company based in the United States, specialises in offering tailored mixing solutions for sectors such as oil and gas, water and wastewater, chemical processing, and power generation, among others.

The Statiflo Group, based in the United Kingdom, is known for its static mixers that facilitate the mixing of liquids, gases, and solids without the demand for moving parts. It offers its services in water treatment, oil and gas, chemicals, and food processing sectors.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

Other major players in the industrial mixers market report are Mixer Systems, Inc., Silverson, and Sulzer Ltd, among others.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

The market is assessed to grow at a CAGR of 5.20% between 2025 and 2034.

The major drivers of the industry, such as the growing demand for high-performance industrial mixers, rising demand from the developing regions, rapid industrialisation and urbanisation, expanding applications in various industries, and growing technological advancements, are expected to aid the market growth.

The key market trends guiding the growth of the market include the growing shift towards automation and the rising demand for PLC based industrial mixers.

The major regions in the industry are North America, Latin America, the Middle East and Africa, Europe, and the Asia Pacific.

The leading technologies of industrial mixers in the market are agitators, paddle mixers, static mixers, ribbon blenders, emulsifiers, drum mixers, and homogenizers, among others.

The significant types of industrial mixers in the industry are solid-solid, solid-liquid, liquid-gas, and liquid-liquid.

The major end use sectors in the market are food and beverages, mineral industry, chemicals, pharmaceuticals, plastic industry, and wastewater, among others.

The major players in the industry are Ekato Group, Philadelphia Mixing Solutions, Ltd., Statiflo Group, Mixer Systems, Inc., Silverson, and Sulzer Ltd, among others.

In 2024, the market reached an approximate value of USD 2.65 Billion.

The market is estimated to witness healthy growth in the forecast period of 2025-2034 to reach a value of around USD 4.40 Billion by 2034.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2024 |

| Historical Period | 2018-2024 |

| Forecast Period | 2025-2034 |

| Scope of the Report |

Historical and Forecast Trends, Industry Drivers and Constraints, Historical and Forecast Market Analysis by Segment:

|

| Breakup by Technology |

|

| Breakup by Type |

|

| Breakup by End Use |

|

| Breakup by Region |

|

| Market Dynamics |

|

| Competitive Landscape |

|

| Companies Covered |

|

| Report Price and Purchase Option | Explore our purchase options that are best suited to your resources and industry needs. |

| Delivery Format | Delivered as an attached PDF and Excel through email, with an option of receiving an editable PPT, according to the purchase option. |

Datasheet

One User

USD 2,499

USD 2,249

tax inclusive*

Single User License

One User

USD 3,999

USD 3,599

tax inclusive*

Five User License

Five User

USD 4,999

USD 4,249

tax inclusive*

Corporate License

Unlimited Users

USD 5,999

USD 5,099

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Our step-by-step guide will help you select, purchase, and access your reports swiftly, ensuring you get the information that drives your decisions, right when you need it.

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City,1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

United States

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

United States (Head Office)

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City, 1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

Share