Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The global hexamine market attained a volume of 659.46 KMT in 2025 and is projected to expand at a CAGR of 3.40% through 2035. The market is further expected to achieve a volume of 921.28 KMT by 2035. A rising shift toward low-VOC phenolic resin applications is accelerating hexamine consumption as insulation, automotive, and engineered wood manufacturers demand cleaner, higher-performance curing agents tailored for advanced material systems.

Leading producers in the global industry are redefining their product portfolios to meet rising specialty chemical demand from resin, pharma, and defense industries. In September 2025, Mitsubishi Gas Chemical Company, Inc. launched a new line of eco-friendly hexamine products designed for the resin industry. The market is also expanding its reach in the automotive industry where OEMs are tightening material specifications for durability and high-temperature resistance, boosting the overall chances of hexamine market expansion. This specific expansion illustrates how suppliers are gradually moving away from undifferentiated commodity output.

Moreover, as downstream industries become more quality-sensitive, manufacturers are refining process controls, purity levels, and supply chain integration to cater to the pharmaceutical sector, where consistency is non-negotiable. Key players like INOLAB Chemicals and Simalin Chemicals are investing in automated nitration and formaldehyde handling systems, which improve both throughput and safety compliance. Considering the demand in the hexamine market, Kanoria Chemicals in February 2024 invested INR 12.70 crore to increase production capacity of hexamine in India. Several buyers in the resin and rubber curing markets have started prioritizing suppliers capable of offering “certified consistency,” making production reliability almost as important as pricing negotiations.

Base Year

Historical Period

Forecast Period

Compound Annual Growth Rate

3.4%

Value in KMT

2026-2035

*this image is indicative*

| Global Hexamine Market Report Summary | Description | Value |

| Base Year | KMT | 2025 |

| Historical Period | KMT | 2019-2025 |

| Forecast Period | KMT | 2026-2035 |

| Market Size 2025 | KMT | 659.46 |

| Market Size 2035 | KMT | 921.28 |

| CAGR 2019-2025 | Percentage | XX% |

| CAGR 2026-2035 | Percentage | 3.40% |

| CAGR 2026-2035 - Market by Region | Asia Pacific | 3.8% |

| CAGR 2026-2035 - Market by Country | India | 4.4% |

| CAGR 2026-2035 - Market by Country | Australia | 4.0% |

| CAGR 2026-2035 - Market by Grade | Unstabilized | 3.6% |

| CAGR 2026-2035 - Market by End Use | Pharmaceuticals | 4.0% |

| Market Share by Country 2025 | USA | 11.6% |

The growing phenolic resin category is a primary contributor to the hexamine market growth, with manufacturers supplying curing agents tailored to high-temperature automotive and construction composites. Producers are launching branded high-purity grades and engineered particle sizes to meet molding compound specifications demanded by OEMs. Recent market studies report sustained resin demand supporting hexamine consumption across laminates, molded parts, and insulation boards, encouraging capacity optimization. In April 2021, Mayzo Inc. announced that it has expanded its additives portfolio to include a high-quality, solvent-based phenolic resin for pressure-sensitive adhesive tapes and labels.

Regulatory pressure on volatile organic compounds and hazardous air pollutants is reshaping hexamine demand as resin manufacturers reformulate to meet cleaner production standards. United States NESHAP and newer polymer industry performance rules require tighter emissions controls, so suppliers are offering lower-impurity hexamine and documented process controls that ease compliance for converters. In October 2024, Bakelite LLC, the sole producer of granular hexamine in the United States filed a petition asking the government to impose antidumping (“AD”) duties on imports of hexamine from China, India, Germany and Saudi Arabia. These regulatory trends in the hexamine market incentivize capital investments in closed-loop handling, better analytics, and certified supply chains to avoid costly retrofits.

Demand from pharmaceutical and defense applications is driving commercialization of certified high-purity hexamine grades with rigorous traceability and analytical support. Producers are investing in dedicated production cells, expanded QC laboratories, and ISO or GMP-aligned documentation so buyers in methenamine-based APIs and energetic precursor chains can qualify suppliers, propelling the hexamine market scope. In October 2024, Norway unveiled a comprehensive roadmap aimed at bolstering the defense industry's production capacity, with an investment of USD 90 million. These investments reduce cross-contamination risk and support regulatory filings, enabling access to higher-margin contracts and long-term supply agreements.

Packaging, particle engineering, and format innovation are clear differentiation levers in hexamine markets where handling and dust control matter to converters. Producers develop coated micro-prills, granules with narrow size distribution, and moisture-stable packaging to reduce hygroscopicity and improve dosing in automated feeders. Pilot programs with converters demonstrate lower rejection rates, fewer line stoppages, and reduced occupational exposure claims, translating into measurable total cost of ownership improvements. Suppliers collaborating with logistics partners and offering vendor-managed inventory pilots gain preference among appliance, insulation, and molding customers seeking operational continuity.

Military procurement cycles and growing commercial demand for solid fuel tablets are prompting strategic capacity projects and inventory programs among hexamine suppliers. Defense and outdoor-equipment buyers focus on predictable multi-year supply, which has led some producers to establish regional warehousing and dedicated production runs near logistics hubs and mining regions, accelerating the hexamine market revenue growth. Market trackers report targeted runs for energetic and fuel-grade hexamine to secure qualified lots and fast delivery during mobilization or seasonal demand.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The EMR’s report titled “Global Hexamine Market Report and Forecast 2026-2035” offers a detailed analysis of the market based on the following segments:

Market Breakup by Grade

Key Insight: As per the hexamine market report, stabilized grades are being largely favored by large-scale resin converters for reliability, certified lots, and automated dosing, while unstabilized grades grow faster in fuel-tablet, mining, and tactical sourcing where cost and flexible supply chains matter. Stabilized suppliers win long-term contracts by investing in process analytics, packaging, and emissions documentation, shortening qualification cycles for OEMs. Conversely, unstabilized players compete on regional tolling, spot programs, and tactical warehousing to capture seasonal demand and defense quotas.

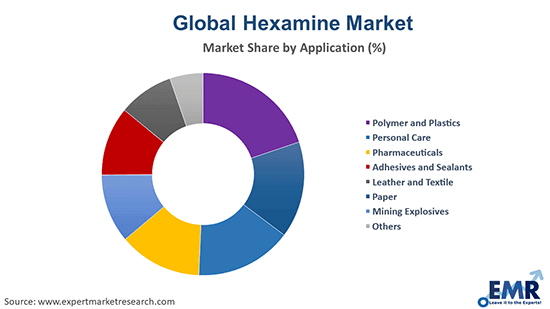

Market Breakup by Application

Key Insight: Among all the applications considered in the report, polymer and plastics occupy the largest demand base due to phenolic resin curing needs and resin-maker partnerships, while pharmaceuticals indicate rapid growth for certified high-purity grades. Adhesives and sealants, leather, and textiles prioritize form factor, coated prills and dosing consistency while personal care uses niche low-impurity streams. Mining explosives and fuel-tablet users emphasize tactical logistics and batch consistency for safety. Paper and other applications value supplier technical support for formulation tweaks, all impacting the hexamine market revenue.

Market Breakup by Region

Key Insight: Regionally, the hexamine market in Asia Pacific leads on scale and integrated value chains, while North America grows rapidly, owing to defense sourcing, stringent compliance, and localized warehousing. Europe demands pharma-grade consistency and regulatory traceability. Latin America favors unstabilized grades for mining and fuel-tablet applications with tactical logistics and Middle East and Africa rely on import hubs, regional warehousing, and opportunistic procurement tied to mining projects.

| CAGR 2026-2035 - Market by | Region |

| Asia Pacific | 3.8% |

| North America | 3.2% |

| Europe | XX% |

| Latin America | XX% |

| Middle East and Africa | XX% |

Stabilized grade dominates the market due to consistent curing performance and certification

Stabilized hexamine grades command the largest market share due to predictable curing kinetics and higher shelf stability demanded by large resin converters. Leading manufacturers have standardized particle engineering and moisture control in bulk sacks, reducing variability in phenolic novolac curing lines and improving first-pass yields for OEMs. In August 2025, Clariant increased production capacity for Nylostab S-EED stabilizer with second production line in Cangzhou, China, accelerating growth in the hexamine market. Stabilized grades also integrate easily into automated dosing systems, lowering line stoppages and occupational exposures, which makes them the procurement choice for scale converters.

| CAGR 2026-2035 - Market by | Grade |

| Unstabilized | 3.6% |

| Stabilized | XX% |

Unsterilized hexamine is becoming the fastest-growing subsegment as niche users seek lower-cost feedstock for fuel-tablet producers and certain mining explosive intermediates. Smaller converters prefer unstablized grades for rapid on-site processing where tight shelf stability is less critical, enabling flexible just-in-time procurement. Suppliers target this market category with regional tolling arrangements and spot-lot programs to capture seasonal demand in outdoor equipment and mining seasons.

By application, polymer plastics account for the major share of the market driven by resin curing, automotive, insulation demand

Polymer and plastics remain the dominant application for hexamine, driven by phenolic resin curing in molded components, laminates, and insulation products. Major resin buyers in automotive and construction specify high-consistency hexamine grades to meet mechanical and fire-resistance targets, pushing suppliers toward tighter impurity specs and customized particle size distributions. Till June 2025, OQ introduced 17 new application-focused polymer grades, reinforcing its commitment to delivering transformative material solutions, further propelling the hexamine industry value.

| CAGR 2026-2035 - Market by | Application |

| Pharmaceuticals | 4.0% |

| Personal Care | 3.8% |

| Polymer and Plastics | 3.7% |

| Adhesives and Sealants | XX% |

| Leather and Textile | XX% |

| Others | XX% |

Pharmaceutical applications observe fast growth in the market for high-purity hexamine driven by demand for methenamine-based APIs and urinary antiseptics requiring strict impurity control and traceability. Suppliers invest in segregated production cells, expanded QC labs, and ISO/GMP-aligned documentation to qualify for regulated tenders and shorten supplier onboarding for pharma buyers. Contract manufacturing organizations prefer partners offering certified analytical packages and stability data to support regulatory submissions.

By region, Asia Pacific leads the market due to chemicals manufacturing scale and export hubs

Asia Pacific dominates hexamine consumption driven by China and India’s dense chemical manufacturing clusters, extensive resin production, and upstream formaldehyde supply chains. Regional players benefit from integrated value chains, lower logistic costs, and proximity to large OEM converters in automotive, construction, and electronics sectors. Suppliers in the region focus on scale optimization, local quality labs, and export-ready packaging to service intra-Asia demand and global buyers. Government industrial policies that favor domestic chemical capacity and export incentives further solidify regional leadership.

North America is among the fastest-growing regional hexamine markets for specialized grades, propelled by defense procurement, automotive lightweighting programs, and stringent environmental standards that push converters toward certified low-impurity inputs. For example, Hexion partners with Canadian government agency Alberta Innovates to accelerate development of next-generation resin chemistries and engineered panel products. Suppliers that demonstrate compliance with EPA rules, provide emissions documentation, and offer localized warehousing gain preferential procurement status with government and large OEM buyers.

| CAGR 2026-2035 - Market by | Country |

| India | 4.4% |

| Australia | 4.0% |

| China | 3.9% |

| Mexico | 3.6% |

| Germany | 3.4% |

| USA | XX% |

| Canada | XX% |

| UK | 3.2% |

| France | XX% |

| Italy | XX% |

| Japan | XX% |

| Saudi Arabia | XX% |

| Brazil | XX% |

Leading hexamine market players are moving beyond commodity sales to offer coated micro-prills, narrow-distribution granules and moisture-stable bulk packaging to reduce hygroscopic losses and dosing variability for converters. There is strong opportunity in certified pharma-grade batches, modular pre-dosed feed packs for automated resin lines, and regional warehousing solutions that can better support tactical defense contracts.

Hexamine companies that are integrating analytics, lot-level traceability, and circular feedstock sourcing command premium procurement slots. Smaller players are adopting tolling models and vendor-managed inventory pilots to capture seasonal outdoor and mining demand without heavy capital outlay. Ultimately, firms investing in customer-centric engineering support, packaging innovation, and compliance documentation are creating stronger B2B relationships and unlocking margin improvement across value chains. Regulatory shifts toward low-VOC resins and defense sourcing standards are accelerating demand for specialized grades, creating near-term procurement windows for agile, certified suppliers.

Kanoria Chemicals & Industries Ltd was founded in 1960 and is headquartered in India. It is a vertically integrated specialty chemicals manufacturer supplying hexamine and formaldehyde derivatives to resin, adhesive, and insulation markets. Kanoria is expanding formaldehyde and hexamine capacity while enhancing packaging and QC analytics to serve automotive and construction resin converters seeking certified lot consistency.

Ascend Performance Materials, headquartered in Houston, Texas and founded in the year 2009, is an established producer of specialty amines including hexamethylenetetramine grades. The company leverages decades of amine expertise to offer engineered HMT products like FlexaTram designed for resins, plastics and personal care markets, impacting the hexamine market.

Ruixing Group Co., Ltd, founded in 1970 and is headquartered in China, operating integrated chemical and fertilizer complexes. Ruixing produces hexamine among other intermediates and is leveraging scale to offer competitive unstabilized grades for mining and fuel-tablet markets. The company is focusing on format innovations like bulk granules and regional warehousing to serve domestic converters and export corridors.

Methanol Chemicals Company Chemanol was established in 1989 and is headquartered in Al Jubail Industrial City, Saudi Arabia. Chemanol supplies formaldehyde and hexamine derivatives to Middle East resin, agrochemical, and industrial customers, leveraging regional feedstock access. The firm is focusing on moisture-stable packaging, certified lot traceability and export-ready formats to serve nearby defense and construction markets.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

Other key players in the market include Simalin Chemical Industries Pvt Ltd, among others.

Unlock the latest insights with our hexamine market trends 2026 report. Discover regional growth patterns, consumer preferences, and key industry players. Stay ahead of competition with trusted data and expert analysis. Download your free sample report today and drive informed decisions in the market.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

The market is projected to grow at a CAGR of 3.40% between 2026 and 2035.

Key strategies driving the market include investing in particle engineering, are piloting vendor-managed inventory, are certifying pharma-grade lots, are building regional warehouses, and are co-developing pre-dosed feed packs with key converters to secure long-term contracts.

The increasing use of hexamine in the production of various organic compounds, the rising utilisation of plastics and polymers, the growing investments by key players in capacity expansion and mergers and acquisition activities are the key trends guiding the market development.

The major regions in the market are North America, Latin America, the Middle East and Africa, Europe, and the Asia Pacific.

The leading grades of hexamine in the market are stabilised and unstabilised.

The major applications of hexamine include polymer and plastics, personal care, pharmaceuticals, adhesives and sealants, leather and textile, paper, and mining explosives, among others.

The key players in the market include Kanoria Chemicals & Industries Ltd, Ascend Performance Materials, Ruixing Group Co., Ltd., Methanol Chemicals Company (Chemanol), and Simalin Chemical Industries Pvt Ltd, among others.

In 2025, the market reached an approximate volume of 659.46 KMT.

The market is estimated to witness healthy growth in the forecast period of 2026-2035 to reach a volume of around 921.28 KMT by 2035.

Supply volatility, raw-material contamination risks, strict regulatory compliance, and the capital intensity of specialized production lines are constraining capacity expansion and increasing qualification time for buyers and suppliers globally.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2025 |

| Historical Period | 2019-2025 |

| Forecast Period | 2026-2035 |

| Scope of the Report |

Historical and Forecast Trends, Industry Drivers and Constraints, Historical and Forecast Market Analysis by Segment:

|

| Breakup by Grade |

|

| Breakup by Application |

|

| Breakup by Region |

|

| Market Dynamics |

|

| Competitive Landscape |

|

| Companies Covered |

|

| Report Price and Purchase Option | Explore our purchase options that are best suited to your resources and industry needs. |

| Delivery Format | Delivered as an attached PDF and Excel through email, with an option of receiving an editable PPT, according to the purchase option. |

Single User License

One User

USD 3,999

USD 3,599

tax inclusive*

Datasheet

One User

USD 2,499

USD 2,249

tax inclusive*

Five User License

Five User

USD 4,999

USD 4,249

tax inclusive*

Corporate License

Unlimited Users

USD 5,999

USD 5,099

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Strategic Solutions for Informed Decision-Making

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share