Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The global chip mounter market value reached around USD 5.45 Billion in 2025. The expansion of electric vehicles (EVs) has significantly increased demand for chip mounters, as a single EV can contain over 3,000 electronic components. Additionally, the rise of 5G technology is necessitating advanced chip mounters capable of handling high-density components required for telecommunications infrastructure. The growing complexity of electronics in consumer devices and the automotive sector is further fuelling demand, as manufacturers seek high-speed, precise equipment to meet production needs. Due to this, the industry is expected to grow at a CAGR of 4.80% during the forecast period of 2026-2035 to attain a value of USD 8.71 Billion by 2035.

Base Year

Historical Period

Forecast Period

The total production volume of consumer electronics is projected to increase from 7,749.2 million pieces in 2018 to 9,014.2 million pieces by 2028, significantly impacting the chip mounter market. This growth in production underscores the rising demand for chip mounters, which are essential for assembling the electronic components in these devices.

Furthermore, according to the International Data Corporation (IDC), global smartphone shipments increased by 9.0% year-on-year to 292.2 million units in Q2 of 2024. This growth in smartphone production highlights the need for efficient chip mounters that can accommodate the complexity of modern electronic components, driving further expansion in the chip mounter market.

Additionally, by 2028, the total production of telephonic devices and TV sets is anticipated to reach around 2,113 million and 2,735 million pieces. Such high production volumes will necessitate advanced chip mounting technologies to ensure precision and speed in assembly processes, leading to chip mounter demand growth.

Compound Annual Growth Rate

4.8%

Value in USD Billion

2026-2035

*this image is indicative*

Chip mounters are automated devices used in electronics manufacturing to accurately position and attach surface-mounted components onto printed circuit boards (PCBs). They help enhance assembly speed, precision, and efficiency in electronic circuit production. Chip mounters can also be used to assemble semiconductors in the electronic industry. Thus, the industry finds major applications in electronic gadgets.

With rising consumer demand and dependence on technology, there is a rapid consumer shift towards smartphones and laptops from desktops, LEDs from LCD television sets, and other household items like washing machines, coffee machines, and others, which have become entirely automated. All these technological advancements and transformations require upgradation in design, user interface, and power processing, which are enabling growth of the chip mounter market.

Chip mounters are significantly used in the miniature electronic devices industry and play a significant role in reducing dimensions of integrated circuits. Hence, the market is expected to be driven by the rising electronic industry and innovations in designs and technology for adding more circuitry in chips without increasing the manufacturing costs. The market is also being driven by the rising disposable incomes, busier lifestyles, and increasing need to automate everyday tasks. The rising penetration of smartphones is also aiding the growth of the industry.

Growing demand in electric vehicles (EVs), shift toward automation and industry 4.0, and rising demand for miniature electronics are the key trends aiding the market growth.

The expansion of electric vehicles (EVs) and increasing automotive electronics complexity has led to a significant rise in chip mounters demand. A single EV can contain over 3,000 electronic components, including sensors, control units, and processors, thus requiring chip mounters to handle larger production volumes. Companies like Panasonic Corporation have developed chip mounters with multi-tasking capabilities, enabling placement speeds of up to 90,000 components per hour. As per industry reports, the rise in EV production, which grew by 40% in recent years, is directly boosting the demand for advanced chip mounters in the automotive sector.

The integration of automation technologies and Industry 4.0 in chip mounting processes is becoming a significant market trend. As per industry reports, automated chip mounters equipped with AI and IoT capabilities can improve productivity by up to 25%. Some factories have also reported a 30% reduction in human errors during production. For example, Fuji Corporation's Smart Factory solutions have enabled manufacturers to increase output by up to 15% while reducing downtime by around 20%. This shift in chip mounter market allows manufacturers to handle the growing demand for smaller and more complex electronics more efficiently.

The dynamics of the market are being significantly impacted by the increasing complexity of electronics in industries like automotive, consumer electronics, and telecommunications. For example, as electric vehicle (EV) production continues to accelerate, global EV sales are projected to reach 14 million units by the end of 2023 and grow further to 17 million units by the end of FY-2024. This surge is driving the need for chip mounters capable of handling intricate components in EV control systems and sensors, resulting in influenced chip mounter market dynamics and trends. Manufacturers are also investing in advanced pick-and-place machines that can handle ultra-fine pitch components with precision within 10 microns to meet the growing demands of the automotive industry.

Another trend affecting the market is the rising adoption of 5G technology. By 2025, over 1.8 billion people are expected to have access to 5G networks. This is significantly increasing the demand for compact and high-density chip mounters, such as those offered by Yamaha’s YSM20 model, which can place up to 95,000 components per hour in telecommunications equipment.

With devices becoming smaller, the demand for chip mounters capable of placing ultra-small components (often less than 0.5mm in size) has surged. Miniaturisation in products like smartphones and wearables requires machines that can place components with accuracy within 10 microns. ASM Pacific Technology has developed machines capable of handling components as small as 0201 metric size (0.25mm x 0.125mm), increasing component placement precision by more than 50%. This trend in the chip mounter market is pushing manufacturers to upgrade their machines to keep up with the downsizing of modern electronics.

One prominent opportunity arises from the increasing adoption of smart manufacturing and automation technologies, particularly in Industry 4.0 environments. Manufacturers are investing in intelligent chip mounters with real-time monitoring and self-optimisation capabilities, like Fuji Corporation’s NXT III platform, which adapts to production changes and improves efficiency by up to 25%.

Other significant chip mounter market opportunities come from the rise of IoT (Internet of Things) devices, which are forecast to exceed 30 billion connected devices by 2030. This surge is creating a demand for chip mounters that can handle compact, high-performance components needed for IoT sensors and devices.

Additionally, the growth of renewable energy technologies, particularly solar and wind power, is driving the need for advanced power electronics, where chip mounters play a critical role in producing reliable inverters and converters. Companies such as Mycronic are grasping this opportunity by offering high-speed placement machines tailoured to the production of power electronics.

One of the primary challenges in the market is the high initial cost of advanced chip mounters, which can range from USD 200,000 to over USD 1 million, making it difficult for small and medium-sized enterprises (SMEs) to invest in such equipment. This restricts chip mounter market penetration in emerging economies where cost sensitivity is high. Additionally, the increasing complexity of semiconductor designs is pushing the limits of current chip mounter technologies. For instance, handling components smaller than 0.2mm with high precision requires expensive upgrades and highly skilled operators, which many manufacturers cannot afford.

Another restraint impacting chip mounter demand forecast is the possibility of semiconductor supply chain disruptions, which can cause delays in the delivery of critical components needed for mounter production. For example, chip shortages in 2021 delayed production cycles across industries (with lead times extending up to 52 weeks). This had a ripple effect on chip mounter manufacturers as it delayed equipment deliveries. In response, companies like Samsung and TSMC have both announced multi-billion-dollar investments in new semiconductor manufacturing facilities to mitigate these risks.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

“Chip Mounter Market Report and Forecast 2026-2035” offers a detailed analysis of the market based on the following segments:

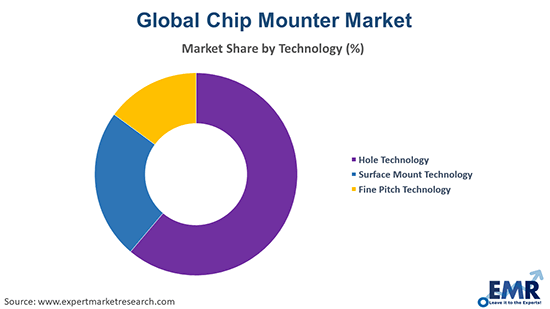

Market Breakup by Technology

Market Breakup by Application

Market Breakup by Region

Market Insights by Technology

Through-hole technology (THT) involves mounting electronic components by inserting leads through holes in the PCB. Although this technology is gradually being replaced by surface mount technology (SMT) for most applications, it remains crucial for military, power electronics, aerospace, and automotive sectors. In September 2023, Panasonic introduced a hybrid chip mounter capable of handling both THT and SMT.

According to chip mounter market analysis, surface mount technology (SMT) is the dominant technology as it enables the placement of components directly onto the surface of PCBs without requiring through-holes. SMT allows for more compact, lighter, and faster electronic assemblies, which are essential for consumer electronics, telecommunications, and automotive applications. Recent advancements in automation, such as Fuji Corporation’s AIMEX III mounter, allow placement speeds of up to 150,000 components per hour, making it highly suitable for consumer electronics and 5G applications. Additionally, in January 2024, Yamaha Motor Co., Ltd. announced the release of the YRM10, a next-generation compact high-speed modular surface mounter, boasting a mounting performance of 52,000 chips per hour (CPH).

In contrast, the fine pitch technology segment in chip mounter market involves the precise placement of ultra-small components (with lead pitches of 0.5mm or smaller) and is primarily used for advanced semiconductor packaging and miniaturised devices, such as IoT devices, smartphones, tablets, and wearable medical implants. The need for accuracy within 10 microns has also pushed manufacturers to develop fine pitch mounters. For example, in 2023, ASM Pacific Technology launched a fine-pitch mounter, which is capable of handling component sizes as small as 01005 (0.4mm x 0.2mm).

Market Insights by Application

Consumer electronics, including smartphones, laptops, wearables, and home appliances, hold the largest chip mounter market share. The demand for compact, high-performance electronic devices is driving innovation in chip mounter technologies, especially for surface mount technology (SMT) and fine-pitch components. In 2023, smartphone shipments reached 1.2 billion units in 2023, further driving this market’s growth. To cater to the rising production levels, Fuji Corporation introduced a new series of high-speed mounters in June 2023 designed to handle the ultra-small components required for 5G smartphones. The medical industry is also seeing rising demand for chip mounters with fine-pitch technology, particularly in wearable devices, imaging equipment, and implantable technologies.

The rollout of 5G networks and advancements in telecommunications infrastructure are factors further driving chip mounter market demand. The rapid deployment of 5G networks, expected to cover 45% of the global population by 2024, is pushing demand for advanced SMT mounters to handle the dense, high-frequency components required for 5G infrastructure.

Lastly, the automotive sector, especially with the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), is driving demand for high-volume chip mounters capable of handling robust and complex electronic assemblies. As per industry reports, electric vehicle sales are projected to account for 20% of all car sales in 2024, where China alone has nearly sold 1.9 million electric cars in Q1 of 2024. With the rising production and sales of EVs, there is a rising need for chip mounters to place sensors, power control units, and other critical components in vehicles.

North America Chip Mounter Market Trends

North America, particularly the United States, is a key player in the market due to its strong presence in advanced electronics, semiconductor manufacturing, and automotive sectors. The region's focus on Industry 4.0 and automation is also propelling the demand for high-performance chip mounters. Moreover, the U.S. has seen increased investments in semiconductor manufacturing, including USD 52 billion in government funding through the CHIPS Act in 2023 to boost local production. Also, in April 2024, Juki Automation Systems showcased its LX-8 high-speed flexible mounter at IPC APEX EXPO in California, United States, which allows for precise component placement and efficient production runs.

Asia Pacific Chip Mounter Market Drivers

Asia Pacific is another dominant region, driven by its strong electronics manufacturing base, particularly in China, Japan, South Korea, and Taiwan. The region's growth is also fuelled by the high demand for consumer electronics, automotive components, and telecommunications equipment. The region's rapid adoption of 5G technology, combined with its leadership in semiconductor manufacturing, continues to drive chip mounter market growth. For example, in September 2024, India and the United States agreed to set up a joint semiconductor fabrication unit in Jewar, Uttar Pradesh, to manufacture infrared, gallium nitride, and silicon carbide chips. The collaboration can reduce India's import bill for semiconductors by an estimated INR 6,000 crore.

Europe Chip Mounter Market Opportunities

Europe holds a significant share in the market, driven by its strong automotive, aerospace, and industrial electronics sectors. In EU, countries like Germany, France, and the UK have the highest number of industrial factories, including automotive and electronic manufacturing facilities, leading to higher demand for chip mounters. The region's focus on electric vehicles (EVs) and sustainability is also boosting the adoption of precision chip mounters, such as those offered by SMT Robotics, which is a Berlin-based start-up. For example, in October 2023, SMT Robotics introduced modular chip mounters for the European automotive and industrial sectors, supporting the growing demand for EV components and advanced manufacturing solutions in the region.

Latin America Chip Mounter Market Growth

The Latin American market is smaller but growing, primarily driven by increasing electronics manufacturing in countries like Brazil and Mexico. The region's emerging industrial sectors and focus on developing local electronics production capacities are contributing to market growth. Moreover, in 2023, Mexico emerged as a key hub for electronics assembly, particularly due to its proximity to North American markets and favourable trade agreements. Also, in July 2023, Yamaha Motor expanded its presence in the LATAM region by launching a chip mounter series for SMEs in the region.

Start-ups are primarily focused on meeting the rising demand for large and small electronic devices. They are leveraging surface mountain and fine pitch technologies to develop efficient, high-speed chip mounters that can quickly adapt to changing production needs. These enterprises aim to create cost-effective solutions that enhance manufacturing processes while ensuring high precision in component placement on compact PCBs. Additionally, start-ups are exploring new applications in emerging sectors like electric vehicles and smart clothing, positioning themselves to gain on diverse chip mounter market opportunities.

OptimumNano Automation, founded in 2017 and based in Shenzhen, China, has rapidly gained recognition for its innovation in the design and production of high-precision chip mounters for the fast-growing electric vehicle (EV) and 5G sectors. The company’s flagship product line, which integrates AI and machine learning technologies, can achieve placement speeds of up to 80,000 components per hour with a 99.99% accuracy rate. The startup's collaboration with leading EV manufacturers and telecommunications giants in China has positioned it as a key chip mounter market player. In 2023, the company also secured several significant contracts for large-scale infrastructure projects in China and expanded its reach into European markets.

SMT Robotics, established in 2016 and headquartered in Berlin, Germany, is known for its flexible and modular chip placement systems. The company introduced a groundbreaking platform in 2019 that allows manufacturers to scale up or down based on production needs without requiring complete system overhauls, which reduced capital expenditure for its clients by up to 20%. SMT Robotics is highly regarded for its innovations in surface mount technology (SMT) and has partnered with several prominent players in the automotive and aerospace industries. In 2022, the startup expanded its operations to North America.

Market players are focused on enhancing their products by integrating advanced features and technologies to stay competitive. This includes incorporating IoT compatibility and parallel nozzle heads into their chip mounters. They are adopting vendor evaluation methodology for filtering products and selecting winning strategies. Moreover, increasing product announcements by companies like Samsung, Apple, Oppo, Xiomi, and Mycronic are invigorating manufacturers to develop more efficient surface chip mounters.

Hanwha Group is a prominent South Korean conglomerate, founded in 1952 as Korea Explosives Co. and headquartered in Seoul. The group operates across aerospace, energy, chemicals, finance, and retail sectors. Over the decades, Hanwha has expanded globally, acquiring numerous companies, and diversifying its portfolio to include renewable energy solutions like solar and wind power. In the FY 2022, the company ranked as the seventh largest business enterprise in South Korea, and it is also listed in Fortune Global 500 companies.

JUKI Corporation, established in 1938 and headquartered in Tokyo, Japan, is a leading manufacturer of industrial sewing machines and automation equipment. Known for its innovation in the textile industry, JUKI offers a wide range of products that cater to both garment manufacturing and other industrial applications. The company has a strong global presence and is recognised for its commitment to quality in sewing machineries.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

In 2025, the market reached an approximate value of USD 5.45 Billion.

The market is assessed to grow at a CAGR of 4.80% between 2026 and 2035.

The market is estimated to witness healthy growth in the forecast period of 2026-2035 to reach a value of around USD 8.71 Billion by 2035.

The major drivers of the market include rising disposable incomes, increasing population, growing electronic industry, and the new designs and technology for adding more circuitry in chips.

The key trends guiding the market include increasing disposable incomes, the growing penetration of smartphones, and surging focus to automate various tasks.

North America, Europe, the Asia Pacific, Latin America, and the Middle East and Africa are the leading regions in the market.

Hole technology, surface mount technology, and fine pitch technology are the significant technologies considered in the market report.

Consumer electronics, medical, automotive, and telecommunications, among others, are the various applications of chip mounter.

The leading players in the market are Hanwha Group and JUKI Corporation, among others.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2025 |

| Historical Period | 2019-2025 |

| Forecast Period | 2026-2035 |

| Scope of the Report |

Historical and Forecast Trends, Industry Drivers and Constraints, Historical and Forecast Market Analysis by Segment:

|

| Breakup by Technology |

|

| Breakup by Application |

|

| Breakup by Region |

|

| Market Dynamics |

|

| Competitive Landscape |

|

| Companies Covered |

|

| Report Price and Purchase Option | Explore our purchase options that are best suited to your resources and industry needs. |

| Delivery Format | Delivered as an attached PDF and Excel through email, with an option of receiving an editable PPT, according to the purchase option. |

Datasheet

One User

USD 2,499

USD 2,249

tax inclusive*

Single User License

One User

USD 3,999

USD 3,599

tax inclusive*

Five User License

Five User

USD 4,999

USD 4,249

tax inclusive*

Corporate License

Unlimited Users

USD 5,999

USD 5,099

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share