Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The polypropylene procurement report indicates a rapid consumption of the material mainly due to its versatile applications across packaging, automotive, and construction industries. Polypropylene, a thermoplastic polymer, is primarily used by buyers in manufacturing packaging films, automotive components, and household products, owing to its durability and cost-effectiveness.

Base Year

Historical Period

Forecast Period

The rising demand for lightweight and fuel-efficient vehicles is boosting polypropylene sourcing in automotive applications, particularly for interior and exterior components. In the packaging segment as per the polypropylene procurement report, the material is gaining traction with increasing use in flexible and rigid packaging applications, mostly because of the booming e-commerce and food-delivery options that are becoming widely available. With polypropylene consumption led by China and India, this quite strong trend of industrialization, urbanization, and increased consumer demand for packaged products makes Asia-Pacific one of the prime regions for polypropylene procurement market.

The expanding production capacity observed in the industry is driving growth due to the rise of investments into bio-based polypropylene and advanced recycling technology. Moreover, according to the polypropylene procurement report, the adoption of circular-economy models and measures to reduce virgin polymer dependence are designed to tap into the regulatory demands, boosting further market growth. Nevertheless, supply chain disturbances, narrow margins, and severe environmental regulations could hinder progress towards stability and profitability.

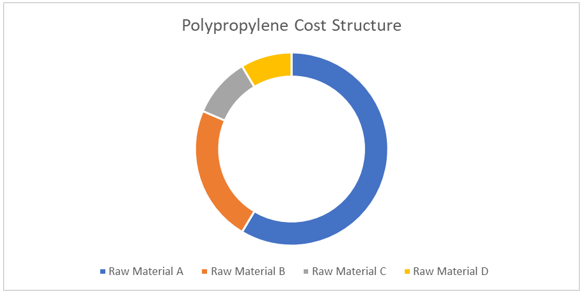

As per the polypropylene procurement report, key factors driving the cost modeling of production can be broadly categorized into seven components including raw materials, energy, catalysts, operating costs, transportation, and regulatory compliance. Among these, it is the raw materials that account for a major chunk of the total cost. The pricing models in the market are being determined mainly by the cost of propylene.

Polypropylene, derived from naphtha cracking or propane dehydrogenation, is one of the most important inputs. The fragility of sourcing is closely associated with fluctuating crude oil and natural gas prices, and hence, naphtha-based production is more vulnerable to volatility in crude oil prices. On the other hand, regions that utilize low-cost propane like the United States have an edge in terms of production cost due to PDH route.

As per the polypropylene procurement report analysis, energy costs exude the highest influence, as the polymerization and extrusion processes for polypropylene remain energy intensive. The variation of energy prices within regional development ranges gives producers in more energy-efficient areas, such as the Middle East, a decided advantage.

Advanced catalysts such as Ziegler-Natta or metallocene-based systems contribute to production costs but enhance polymer properties and yield. Other cost factors include the cost of stabilizers, antioxidants, and other additives.

Labor, plant maintenance, and overheads are the primary operational costs considered in the polypropylene procurement market report. The maintenance of polymerization reactors with high capacities constitutes a quite significant permanent expense for producers. Transportation and logistics costs are influenced by the proximity of production facilities to feedstock sources and end-use markets. Polypropylene pellets are generally shipped, with appropriate precautions against contamination.

Stringent environmental regulations further influence the overall pricing strategies in the polypropylene procurement market through emissions and waste management compliance regulations. Investments made towards the creation of sustainable production processes are expected to gradually change the cost dynamics including recycling technologies and bio-based alternatives.

Polypropylene feedstock costs, energy prices, and global supply-demand dynamics basically govern the strategic pricing in the market. Propylene obtained from crude oil or natural gas comprises a larger fraction of production costs making polypropylene prices remain sensitive to changes in crude oil prices. According to the polypropylene procurement report, the proliferation of propane dehydrogenation technology in the United States and the Middle East offers cost advantages, providing stability in prices in those areas.

In recent times, strong upward pressure on polypropylene price has been observed because of increased demand from the packaging and automotive sectors, especially in the Asia-Pacific region, where industrialization and urbanization have spurred demand. In addition, environmental regulations, particularly in Europe, have affected production costs, with compliance measures raising operational costs. On the other hand, according to the polypropylene procurement report, innovations in recycling technologies and increased production of bio-based polypropylene are expected to restrict long-term price oscillations and augment supply security. In short, capacity expansions in Asia-Pacific, spearheaded by China, would meet growing demand, stabilizing prices in the region.

Cost optimization, supply reliability, and quality assurance characterize the best practices for polypropylene sourcing. Long-term contracts with polypropylene suppliers are crucial, in terms of negotiation strategies, especially with naphtha-based and PDH feedstocks. Buyers prefer sourcing from regions like the Middle East and the United States, where feedstock costs are lower.

According to the polypropylene procurement report, diversification of suppliers will lessen risks posed by geopolitical tensions or supply disruptions, while partnerships with producers of recycled or bio-based polypropylene will help align with sustainability objectives. Efficient logistics is essential, given that polypropylene pellets require contamination-free handling and storage, preferably near key markets. Digital tools that are built on market intelligence offer better forecasting capabilities, allowing existing and ever-tighter cost control to ensure supply chain resilience in volatile markets.

Founded in 2007, LyondellBasell is a worldwide leader in chemicals that develops innovative polymers and polyolefin technologies, creating sustainable solutions for transport, food safety, clean water, healthcare, and the circular low-carbon economy.

China Petrochemical Corporation (Sinopec Group), established in 1998 and headquartered in Beijing, is a leading energy and petrochemical conglomerate, as per the polypropylene procurement report. With integrated operations across exploration, refining, trading, and new energy, Sinopec drives industrial innovation, manages state assets, and offers diversified solutions in oil, gas, chemicals, renewables, engineering, and international logistics.

Founded in 1998 and with its headquarters in Beijing, Sinopec Group, or the China Petrochemical Corporation, is one of the leading energy and petrochemical conglomerates in the world that has integrated operations across exploration, refining, trading, and new energy to stimulate industrial innovation, state asset management, and diversified solutions in oil, gas, chemicals, renewables, engineering, and international logistics.

Braskem, established in 2002, is a leading global producer of thermoplastic resins (PE, PP, PVC) and a major player in the petrochemical sector. Headquartered in Brazil, it specializes in green polyethylene from renewable sugarcane and serves diverse industries, contributing to sustainable solutions in housing, food, and mobility.

ExxonMobil, formed in 1999, is a global leader in energy production, refining, and technology. It is committed to meeting growing energy demand, reducing emissions, and leading the energy transition while creating sustainable value for stakeholders and society.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

The polypropylene procurement market is estimated to be valued at 94.38 MMT in 2025.

As per polypropylene procurement report the industry is projected to grow at a CAGR of 4.50% between 2026 and 2031.

The polypropylene demand is projected to grow to 122.91 MMT by 2031.

The polypropylene production, as per the polypropylene procurement report, is concentrated in Asia Pacific and Middle East regions.

According to the polypropylene procurement report, key drivers of the market is the material’s widespread applications in industries such as packaging and automobile.

As per the polypropylene procurement report analysis, the industry is divided into injection molding, fiber, film, blow molding, extrusion coating, and others.

The primary raw materials used in polypropylene production are propylene, derived from naphtha cracking, propane dehydrogenation (PDH), or as a by-product of oil refining and natural gas processing.

The competitive landscape consists of LyondellBasell Industries Holdings B.V., Sinopec Plastic Co. Ltd., PetroChina Company Limited, Braskem SA, Exxon Mobil Corporation, Formosa Plastics Corporation, U.S.A. (FPC USA), Reliance Industries Limited, TotalEnergies SE, Borealis AG, SABIC, and Carmel Olefins Ltd. among others.

As per the market research for procurement professionals in the industry, best practices include competitive pricing, securing consistent material supply, verifying supplier certifications, optimizing inventory management, and integrating sustainable and innovative sourcing strategies.

The industry is broken down into North America, Europe, Middle East and Africa, Asia Pacific, and Latin America.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2031 |

| Growth Rate | CAGR of 4.50 from 2026 to 2031 |

| Regional Cost Structure | Key Cost Indicators, Cost Breakdown by Component |

| Raw Material Market Outlook | Raw Material Market Analysis, Mapping of Key Raw Material Suppliers, Availability of Raw Material by Region, Pricing Outlook of Key Raw Materials |

| Key Sourcing Strategies | Vendor/Supplier Selection, Price and Contract Model Structure, Sourcing Model, Negotiation Strategy |

| Supplier Analysis | Supplier Selection, Key Global Players, Key Regional Players, Supplier Profiles and SWOT Analysis, Innovation and Sustainability |

| Companies Covered | LyondellBasell Industries Holdings B.V., Sinopec Plastic Co. Ltd., PetroChina Company Limited, Braskem SA, Exxon Mobil Corporation, Formosa Plastics Corporation, U.S.A. (FPC USA), SABIC, Reliance Industries Limited, TotalEnergies SE, Borealis AG, and Carmel Olefins Ltd. among others. |

Single User License

One User

USD 4,399

USD 3,959

tax inclusive*

Datasheet

One User

USD 2,999

USD 2,699

tax inclusive*

Five User License

Five User

USD 5,599

USD 4,759

tax inclusive*

Corporate License

Unlimited Users

USD 6,659

USD 5,660

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share