Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The polymer binder procurement report states that the market showed strong growth in consumption as a result of the material’s mixed mode of applications across construction, coatings, textiles, and adhesives. Polymer binders are vital to the production of paints, coatings, and cementitious materials in enhancing durability and flexibility. Their adhesion and water resistance attributes have made them indispensable in construction and in the development of other infrastructures.

Base Year

Historical Period

Forecast Period

The major impetus for the demand in the polymer binder procurement market is the construction industry, where their application in mortars, plasters, and sealants is seeing an increase. The coatings industry polymer binder sourcing to achieve a superior finish and longer life, more so in architectural and industrial applications.

According to the polymer binder procurement report, the Asia-Pacific region has emerged at the forefront, propelled by rapid urbanization, infrastructural investments, and additional demand for advanced construction materials. China and India are leading this growth because of their high volume of construction and industrial projects.

Further, innovations in low-VOC binders are gaining momentum, particularly in the developed regions of North America and Europe. Production capacities powered by technological improvements are substantially meeting the fast-growing demand directed from the buyers within the supply sector growing. Further challenges, including volatile raw material prices and energy costs as well as regulatory compliance to environmental standards, will be influential to industry dynamics, according to the polymer binder procurement report. Nevertheless, these concerns will be mitigated by the continued emphasis upon green construction practices, efforts directed at technological advancement of binder formulations in the polymer binder market.

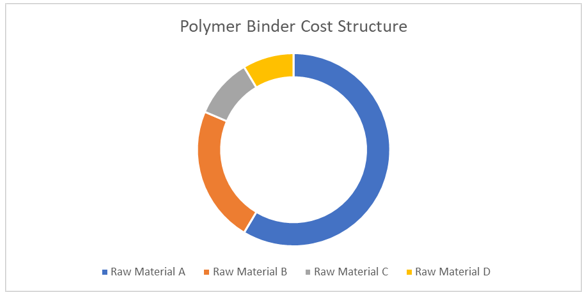

The cost modeling of polymer binder sourcing is based on primary key factors, namely raw materials, energy, catalysts, overhead expense, and regulatory compliance. Among all these, raw materials accounted for the largest cost component in the polymer binder procurement market. The price of methanol, a primary feedstock in the methanol carbonylation process, determines pricing trends in terms of production. Changes in price are determined by how gas and crude oil transform in the marketplace.

Energy costs play a big role in polymer binder production as the polymerization and drying process requires excessive energy. If the cost of energy is higher in a given region, production costs might be therefore higher, and it might cripple the competitiveness in terms of pricing strategies in that region's industry. The price of raw materials like vinyl acetate and styrene, which are petrochemical derivatives, also have a direct bearing on the cost of production, especially in periodic outbursts.

Labor, plant maintenance, and overhead costs also comprise a huge part of the pricing models as per the polymer binder procurement report. Effective management of the plant assures minimal operating costs. Moreover, polymer binders are transported as bulk liquids, hence, transportation costs and logistics depend heavily on the location of the production facility with respect to suppliers of raw materials, as well as the end-user sectors in which products from polymer binder can be applied.

According to the polymer binder procurement report, environmental regulations further influence production costs, particularly in regions with strict emission and waste management policies. Compliance requires investments in sustainable production technologies and emissions control systems, increasing operational expenditure. However, the rise of bio-based polymer binders is creating a shift in strategic purchasing, offering a more sustainable alternative while reducing reliance on fossil-based inputs. These factors collectively determine the competitive pricing and industry dynamics of polymer binders on a global scale.

Pricing models for polymer binders are highly driven by fluctuations in raw materials, production technology, and by demand across many industries. Some of the primary raw materials include polyvinylidene fluoride (PVDF), polyacrylic acid, styrene-butadiene rubber/carboxymethyl cellulose (SBR/CMC), and vinyl acetate, which will greatly influence the cost, keeping them invariably tied to the movements of crude oil prices and those in relevant petrochemical sectors. Recently, polymer binder procurement market experienced an uptrend due to resurgent demand from the construction, textiles, and packaging sectors as Asian markets gained further activity. Further, according to the polymer binder procurement report, supply chain disruptions, heightened energy prices, and stringent standards in the regulatory environment also increased prices. However, the emergence of sustainable production methods and bio-based polymer binders may slow price volatility and provide a more stable outlook for the market in the future.

Procurement best practices in the polymer binder market include securing a consistent supply of raw materials, managing costs, and adhering to quality standards. Key strategies include establishing long-term contracts with suppliers for critical inputs like resins, monomers, and additives, and reducing exposure to market price fluctuations. According to the polymer binder procurement report, companies can diversify supplier networks across multiple regions to minimize risks related to geopolitical and supply chain disruptions. Increasingly, polymer binder procurement emphasizes sourcing materials that align with environmental and sustainability standards, reflecting the industry's focus on eco-friendly formulations.

Efficient supply chain logistics and storage systems are essential, as polymer binders often require precise handling to maintain their quality and performance. Further, adopting advanced procurement technologies, including digital marketplaces and data-driven forecasting tools, enhances cost efficiency and ensures agility in responding to industry demands, strengthening overall supply chain resilience.

Formed in 1897 and headquartered in Michigan, United States, The Dow Chemical Company has become a distinguished global conglomerate specializing in chemical, recognized for its wide range of chemicals, plastics, and sealants.

Formed in 1914 and headquartered in Munich, Germany, Wacker Chemie AG is a global company which offers VINNACEL. WACKER's advanced polymer binder solution, enhances adhesion, cohesion, and durability in cementitious systems, delivering optimized performance tailored to customer-specific applications.

Formed in 1918 and headquartered in Texas, United States, Celanese Corporation, a global technology leader, as per the polymer binder procurement report, produces specialty materials and chemicals integral to everyday life, with manufacturing facilities across North America, Europe, and Asia.

Formed in 2004 and headquartered in Colombes, France, Arkema S.A. is a publicly listed multinational manufacturer of specialty materials, comprising three divisions: adhesives, advanced materials, and coatings, alongside a segment for chemical intermediates.

Formed in 1865 and headquartered in Ludwigshafen, Germany, BASF SE, a publicly traded global leader in chemical manufacturing, operates through diverse segments such as chemicals, materials, industrial solutions, surface technologies, nutrition and care, and agricultural solutions. Its portfolio supports various industries, emphasizing innovative and sustainable solutions to address worldwide challenges.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

The polymer binder market is estimated to be valued at USD 35.32 Billion in 2025.

As per polymer binder procurement report the industry is projected to grow at a CAGR of 7.90% between 2026 and 2031.

The polymer binder demand is projected to grow to USD 55.74 Billion by 2031.

As per the polymer binder procurement report, polymer binder production is concentrated in the Asia Pacific region.

The major drivers of polymer binder consumption, according to the polymer binder procurement report, include increasing demand in the construction, automotive, and textile industries, advancements in polymer technology, and rising adoption of eco-friendly and sustainable materials.

By form, the industry is divided into liquid, powder, and high solids, in accordance with the polymer binder procurement report.

The primary raw materials used are thermoplastics, polyurethane, and poly (styrene-butadiene-styrene) (SBS).

The competitive landscape consists of The Dow Chemical Company, Wacker Chemie AG, Celanese Corporation, Arkema SA, Trinseo PLC, BASF SE, Zsivira Chemie Merk Private Limited, The Lubrizol Corporation, and Evonik SA among others.

Best practices as per market research for procurement professionals in the polymer binder industry emphasize consistent quality assurance, cost management, compliance with environmental regulations, secure logistics, and fostering reliable, scalable supplier relationships.

As per the polymer binder procurement report, the industry is broken down into North America, Europe, Middle East and Africa, Asia Pacific, and Latin America.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2031 |

| Growth Rate | CAGR of 7.90 from 2026 to 2031 |

| Regional Cost Structure | Key Cost Indicators, Cost Breakdown by Component |

| Raw Material Market Outlook | Raw Material Market Analysis, Mapping of Key Raw Material Suppliers, Availability of Raw Material by Region, Pricing Outlook of Key Raw Materials |

| Key Sourcing Strategies | Vendor/Supplier Selection, Price and Contract Model Structure, Sourcing Model, Negotiation Strategy |

| Supplier Analysis | Supplier Selection, Key Global Players, Key Regional Players, Supplier Profiles and SWOT Analysis, Innovation and Sustainability |

| Companies Covered | The Dow Chemical Company, Wacker Chemie AG, Celanese Corporation, Arkema SA, Trinseo PLC, BASF SE, Zsivira Chemie Merk Private Limited, The Lubrizol Corporation, and Evonik SA among others. |

Datasheet

One User

USD 2,999

USD 2,699

tax inclusive*

Single User License

One User

USD 4,399

USD 3,959

tax inclusive*

Five User License

Five User

USD 5,599

USD 4,759

tax inclusive*

Corporate License

Unlimited Users

USD 6,659

USD 5,660

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share