Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

Global consumption of polyisobutylene (PIB) is steadily on the rise, driven by its wide range applications in the automotive, adhesives and lubricant industries. As a material with notable flexibility, impermeability, and high resistance to weathering, PIB is essential in the manufacturing of sealants, fuel additives, as well as inner tyre liners.

Base Year

Historical Period

Forecast Period

As per polyisobutylene procurement report, demand is mainly driven by the automotive sector, where PIB is used in fuel additives to improve the efficiency of the engine and in tyre production for increased durability. The growth of the packaging and construction industries supports demand further because PIB-based adhesives and sealants are gaining acceptance, thus aiding the polyisobutylene sourcing. The Asia-Pacific region is the largest production and consumption base, driven by its growing industrial base, especially in China and India, leading to an increase in this category.

On the supply side, manufacturers are increasing production capacities to meet the rising demand and gaining the attention of the buyers. However, volatility in raw material costs and environmental regulations could affect the dynamics of supply. In accordance with the polyisobutylene procurement report, sustainability concerns are driving producers toward bio-based PIB alternatives, diversifying supply sources and catering to eco-conscious markets.

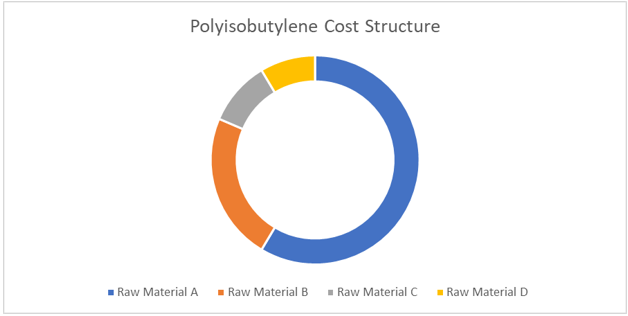

The cost modeling for the production of polyisobutylene in the polyisobutylene procurement market report is influenced by a number of factors that affect the overall expenses. Raw materials are the largest component of these costs, and isobutylene is the primary feedstock. Isobutylene is obtained through refinery or petrochemical processes, and its price is closely tied to fluctuations in crude oil and natural gas markets. Therefore, changes in energy prices can significantly affect the cost of obtaining this essential raw material and help develop better negotiation strategies.

As per the polyisobutylene procurement market report, energy consumption represents another critical element in PIB production costs. The polymerisation process for the manufacture of PIB is energy-intensive, and areas with higher energy prices tend to incur higher operational costs.

Operational costs are also an important consideration in the polyisobutylene procurement report and may differ greatly due to regional factors. Labor, maintenance, and overheads expenses depend on local wage levels and infrastructure. But in many ways, automation and modern production technologies have minimized these costs.

Regulation further adds financial cost, especially if the region's environmental and safety standards are stricter, thereby restricting smooth services. Emissions control policies as well as other regulatory requirements cost more, as per the polyisobutylene procurement report.

Transportation costs are another factor that has an impact on the pricing of PIB. Since PIB is viscous, it necessitates special handling and transportation arrangements, which in turn increase logistics costs. Its production facilities must be close to key markets and end-users as well, otherwise, transportation outlays will increase with distance.

In the polyisobutylene procurement report, PIB prices change with the shift in raw material and energy input costs, coupled with changes in demand in principal industries. Within the last years, prices were driven up mainly by the escalating crude oil price and supply-chain disruptions. Rebounding demand by the automotive and packaging industries continue to exert strong upward pressure, especially in the emerging economies. Future price stability could be expected mainly because of advancements in production technology, such as bio-based manufacturing of PIB. Investments of major players for capacity expansions also balance supply demand dynamics and therefore may not permit sharp price rises and thus supporting a positive long-term outlook in polyisobutylene procurement report.

Efficient procurement strategies in the polyisobutylene industry are crucial for managing the pricing models, price volatility and ensuring a reliable supply of polyisobutylene (PIB). Long-term contracts with suppliers help stabilize costs, while supplier diversification reduces dependency on specific regions, mitigating risks during disruptions. In this polyisobutylene procurement report, emphasis on sustainability through sourcing from bio-based producers aligns with environmental goals and market preferences. Effective inventory management minimizes supply chain delays, and digital tools enhance forecasting and cost optimization, thus leading to strategic purchasing. This strategic partnership with suppliers also allows for co-development of innovative solutions to ensure consistent access to high-quality PIB and foster supply chain resilience. All these approaches work together to improve procurement efficiency and long-term stability in the PIB market.

BASF SE, founded in 1865, is a global leader in the chemical industry, headquartered in Ludwigshafen, Germany. Renowned for its innovation and sustainability efforts, BASF specialises in advanced chemical solutions, including polyisobutylene (PIB).

Kothari Petrochemicals Limited, founded in 1989, headquartered in Chennai, India, is a prominent manufacturer of polyisobutylene (PIB). As per the polyisobutylene procurement report. as part of the Kothari Group, the company is recognised for its high-quality products and reliable supply chains.

Ineos Group Ltd, founded in 1998, based in the United Kingdom, is one of the world’s largest chemical producers, with operations spanning multiple sectors, including petrochemicals and specialty chemicals.

Reliance Industries Limited, established in 1957, headquartered in Mumbai, India, is a multinational conglomerate with a significant presence in petrochemicals, refining, and energy. It is one of the largest producers of polyisobutylene in India.

The Lubrizol Corporation, formed in 1928, headquartered in the United States, is a global leader in speciality chemicals. It is renowned for its advanced additive technologies and polyisobutylene products tailored for automotive, industrial, and consumer markets.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

The polyisobutylene market is estimated to be valued at USD 3.27 Billion in 2025.

As per polyisobutylene procurement report the industry is projected to grow at a CAGR of 5.90% between 2026 and 2031.

The polyisobutylene market is projected to grow to USD 4.61 Billion by 2031.

The global polyisobutylene consumption is experiencing significant growth, driven by its widespread applications in industries such as automotive, adhesives, lubricants, and others.

By product type, the market is divided into conventional PIB and highly reactive PIB.

The primary raw materials used are isobutylene, butene, and catalysts.

Procurement best practices in the polyisobutylene industry include supplier qualification, quality assurance, regulatory compliance, cost optimisation, sustainable sourcing, risk management, inventory control, long-term contracts, market analysis, and supply chain diversification.

The competitive landscape consists of BASF SE, Kothari Petrochemicals Limited, Ineos Group Ltd, Reliance Industries Limited., and The Lubrizol Corporation, among others.

The market is broken down into North America, Europe Middle East and Africa, Asia Pacific, and Latin America.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2031 |

| Growth Rate | CAGR of 5.90 from 2026 to 2031 |

| Regional Cost Structure | Key Cost Indicators, Cost Breakdown by Component |

| Raw Material Market Outlook | Raw Material Market Analysis, Mapping of Key Raw Material Suppliers, Availability of Raw Material by Region, Pricing Outlook of Key Raw Materials |

| Key Sourcing Strategies | Vendor/Supplier Selection, Price and Contract Model Structure, Sourcing Model, Negotiation Strategy |

| Supplier Analysis | Supplier Selection, Key Global Players, Key Regional Players, Supplier Profiles and SWOT Analysis, Innovation and Sustainability |

| Companies Covered | BASF SE, Kothari Petrochemicals Limited, Ineos Group Ltd, Reliance Industries Limited., and The Lubrizol Corporation, among others. |

Datasheet

One User

USD 2,999

USD 2,699

tax inclusive*

Single User License

One User

USD 4,399

USD 3,959

tax inclusive*

Five User License

Five User

USD 5,599

USD 4,759

tax inclusive*

Corporate License

Unlimited Users

USD 6,659

USD 5,660

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share