Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

Global consumption of polybutadiene is increasing at a very high rate. This is ascribed to several key factors pertaining to various industries. As per the polybutadiene procurement report, growth in the automotive industry, including many emerging economies, is driving demand for tires and subsequently for polybutadiene. Higher emphasis on tire performance in terms of fuel efficiency, grip, and durability leads to a higher utilization of polybutadiene in the tire compound.

Base Year

Historical Year

Forecast Year

The polymer modification sector is also contributing to market growth, as polybutadiene enhances the properties of other polymers, improving impact resistance and flexibility. This has applications in various industries, including automotive, construction, and consumer goods. Additionally, the growing emphasis on infrastructure development and industrialization in regions like Asia Pacific is creating new opportunities for polybutadiene applications. The market is further bolstered by ongoing research and development efforts, resulting in new polybutadiene-based compounds with enhanced characteristics. As manufacturers expand their production capacities to meet rising demand, the global polybutadiene consumption trajectory remains firmly upward. The increasing need for strategic sourcing in the market has been highlighted in the latest polybutadiene procurement report.

Asia Pacific, particularly Northeast Asia, stands as the leading region in both production and consumption of polybutadiene. China dominates this landscape, accounting for a significant portion of global demand and production capacity. The main driver of this region's dominance is its thriving automotive industry, which is the biggest consumer of polybutadiene for the manufacture of tires. Rapid expansion in vehicle production and sales in countries such as China, India, and Japan have boosted demand for polybutadiene. Furthermore, industrial rubber and footwear industries in this region are also expanding, contributing to the region's consumption leadership. The presence of major polybutadiene producers and ongoing capacity expansions in the region further confirm Asia Pacific as a stronghold. The economic development, rising disposable income, and urbanization across the region continue to fuel polybutadiene market growth. Insights from the latest polybutadiene procurement report indicate that buyers in this market are increasingly focusing on long-term supplier partnerships.

In the recent period, several significant manufacturers have invested in expanding polybutadiene production capacities. In 2023, Arlanxeo inaugurated a new production line in Brazil, which increased its capacity by 65,000 metric tons per year. In 2022, Indian Oil Corporation Limited announced the construction of a state-of-the-art polybutadiene rubber plant with a 60 kiloton per annum capacity in Panipat. Resin Solutions also increased its hydroxyl-terminated polybutadiene production at its Channelview, Texas facility, which was scheduled to start up in 2024. Companies are leveraging market research for procurement professionals to assess investment feasibility, as stated in the polybutadiene procurement report.

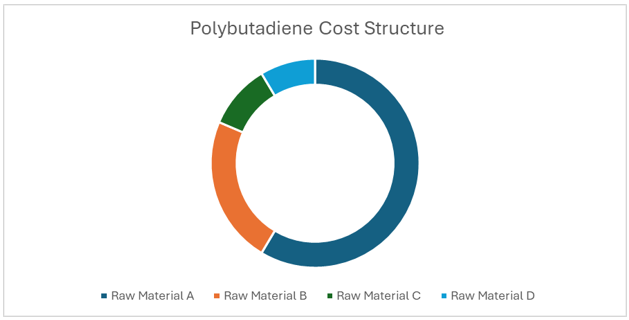

Raw materials are a significant determinant of the cost structure of polybutadiene. The most basic raw material, butadiene, is a by-product of petroleum refining, and its price is closely tied to oil market fluctuations. Butadiene prices directly impact production costs because they are volatile. Other raw materials such as catalysts and solvents also increase the overall costs. The industry closely monitors supply and price variations of these materials, as any changes can disrupt production schedules and impact profitability. Some manufacturers have integrated production facilities, producing their own raw materials to reduce costs and ensure a steady supply, which can provide a competitive advantage in managing raw material expenses. The polybutadiene procurement report highlights the importance of cost modeling in optimizing procurement strategies.

Energy costs play a crucial role in polybutadiene production due to the energy-intensive nature of the manufacturing process. High temperatures and special equipment make the production highly electricity and energy-consuming. Due to fluctuations in energy prices across the globe, polybutadiene producers face significant pressure that may result in increased production costs. To deal with rising energy prices, manufacturers may invest in energy-efficient technologies or seek alternative energy sources. Energy consumption management and optimization can significantly impact the overall cost structure and competitiveness of polybutadiene production. The polybutadiene procurement report discusses procurement best practices for managing energy-related costs.

The operational cost for the production of polybutadiene includes maintenance of special equipment, labor cost for skilled workers, quality control measures, and research and development for improving product formulations. The process involved in producing the product requires high-quality control and testing processes, thus adding to the cost of operation. Further, continuous maintenance of the production plants and dealing with hazardous materials increase the costs. One of the great challenges for manufacturers is managing such costs effectively while maintaining competitiveness. Strategic purchasing, as mentioned in the polybutadiene procurement report, is critical for optimizing operational expenses.

Regulatory compliance is yet another added cost structure for polybutadiene production as it goes against environmental regulations, but tight safety and quality standards set aside for the product. This ranges from proper waste management systems to necessary certifications and workplace safety. The costs can be very significant, including those for environmental monitoring, safety equipment, and documentation processes. As regulations evolve, producers may need to invest in new technologies or modify existing processes to remain compliant, further impacting the overall cost structure of polybutadiene production. Negotiation strategies discussed in the polybutadiene procurement report can help companies manage compliance-related expenses.

Polybutadiene price trends are influenced by several key factors. According to the polybutadiene procurement report, the cost of raw materials, particularly butadiene, plays a significant role as it is derived from petroleum refining. Fluctuations in crude oil prices directly impact butadiene costs, affecting polybutadiene pricing. Energy costs for the energy-intensive production process also contribute to price variations. Market demand, especially from the automotive and tire industries, influences pricing dynamics. Supply chain disruptions, such as those caused by geopolitical events or natural disasters, can lead to price volatility. Additionally, regulatory compliance costs and environmental concerns shape pricing strategies. The polybutadiene procurement report explores pricing trends and strategies to mitigate price fluctuations.

Effective procurement practices for polybutadiene involve a strategic approach to ensure cost-efficiency and supply stability. Raw material costs, especially butadiene derived from petroleum refining, have a significant impact on procurement decisions. Energy costs for the production process also play a crucial role. Market demand, especially from the automotive and tire industries, shapes purchasing strategies. Regulatory compliance, including environmental and safety standards, affects supplier selection. Supply chain disruptions and geopolitical events can lead to shifts in sourcing strategies. The polybutadiene procurement report offers insights into procurement market trends and strategic approaches for securing reliable supply chains.

Technological advancements in production processes and the development of sustainable alternatives may influence procurement choices. Additionally, long-term contracts and partnerships with suppliers are often established to ensure consistent supply and quality while managing price volatility. As highlighted in the polybutadiene procurement report, procurement professionals must adapt their strategies to navigate the evolving market landscape and optimize sourcing decisions.

ENEOS Corporation was founded in 1888 and is headquartered in Japan. The company operates across petroleum refining, marketing, and exploration, as well as metals and materials production.

ARLANXEO Holding B.V. was established in 2016 and is headquartered in the Netherlands. The company operates within the manufacture of synthetic rubber in primary form industry. As per the polybutadiene procurement report, the company has a presence in over 11 production sites across 8 countries and 5 innovation centres.

UBE Corporation was founded in 1897 and is headquartered in Japan. The company specialises in chemicals, plastics, battery materials, pharmaceuticals, cement, construction materials, and machinery. UBE operates through six core business units and has a global presence with facilities in Thailand, Spain, China, and the United States.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

In July 2022, Evonik introduced POLYVEST® eCO, a sustainable liquid polybutadiene range that reduces fossil raw material usage by up to 99.9%. As per the polybutadiene procurement report, the product, launched from their Marl, Germany, facility with ISCC PLUS certification, maintains identical physiochemical properties to fossil-based alternatives, requiring no implementation changes for customers. It serves as a raw material for adhesives, sealants, and tire production, supporting the transition to a circular bioeconomy.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

The Polybutadiene market is estimated to be valued at USD 7.61 Billion.

The industry is projected to grow at a CAGR of 5.00% between 2025 and 2030.

The Polybutadiene demand is projected to grow to USD 10.20 Billion by 2030.

The polybutadiene production is concentrated in Asia Pacific, particularly in China.

The global polybutadiene consumption is primarily driven by automotive industry expansion, increasing tire demand, infrastructure development, rising electric vehicle adoption, and growing applications in healthcare and consumer goods sectors.

By application, the market is divided into tyre manufacturing, polymer modification, industrial rubber manufacturing, and others.

The primary raw materials used are butadiene, catalysts and chemical components, and solvents among others.

The polybutadiene industry employs strategic sourcing, supplier relationship management, cost optimization, and sustainable procurement practices. Companies focus on quality control, risk mitigation, and leveraging technology to ensure consistent supply.

The competitive landscape consists of ENEOS Corporation, ARLANXEO Holding B.V., UBE Corporation, Reliance Industries Limited, and Versalis SpA among others.

The market is broken down into North America, Europe, Middle East and Africa, Asia Pacific, and Latin America.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2030 |

| Growth Rate | CAGR of 5.00 from 2025 to 2030 |

| Regional Cost Structure | Key Cost Indicators, Cost Breakdown by Component |

| Raw Material Market Outlook | Raw Material Market Analysis, Mapping of Key Raw Material Suppliers, Availability of Raw Material by Region, Pricing Outlook of Key Raw Materials |

| Key Sourcing Strategies | Vendor/Supplier Selection, Price and Contract Model Structure, Sourcing Model, Negotiation Strategy |

| Supplier Analysis | Supplier Selection, Key Global Players, Key Regional Players, Supplier Profiles and SWOT Analysis, Innovation and Sustainability |

| Companies Covered | ENEOS Corporation, ARLANXEO Holding B.V., UBE Corporation, Reliance Industries Limited, and Versalis SpA among others. |

Datasheet

One User

USD 2,999

USD 2,699

tax inclusive*

Single User License

One User

USD 4,399

USD 3,959

tax inclusive*

Five User License

Five User

USD 5,599

USD 4,759

tax inclusive*

Corporate License

Unlimited Users

USD 6,659

USD 5,660

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Our step-by-step guide will help you select, purchase, and access your reports swiftly, ensuring you get the information that drives your decisions, right when you need it.

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City,1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

United States

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

United States (Head Office)

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City, 1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

Share