Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

According to the plastic resins procurement report, industry practices focus on securing reliable, cost-effective supply chains, ensuring product quality, and adhering to regulatory standards and category management. To address raw material price volatility, companies frequently enter long-term agreements with cotton and wood pulp suppliers. Diversifying supplier sources across various regions is crucial for minimizing reliance on a single supplier, pricing strategies, ensuring supply stability.

Base Year

Historical Period

Forecast Period

Sustainability is increasingly important in procurement, with more companies seeking suppliers that meet environmental standards. Since plastic resins production can have significant environmental impacts, especially concerning emissions and energy consumption, companies are exploring eco-friendly production methods, such as bio-based plastic resins, to reduce reliance on traditional feedstocks, as mentioned in the plastic resins procurement report. Additionally, advanced procurement technologies, such as digital platforms and market intelligence tools, are being utilized to enhance supply chain efficiency, improve pricing trend forecasts, and manage inventory more effectively. This helps strengthen sourcing resilience, negotiation strategies, and cost efficiency.

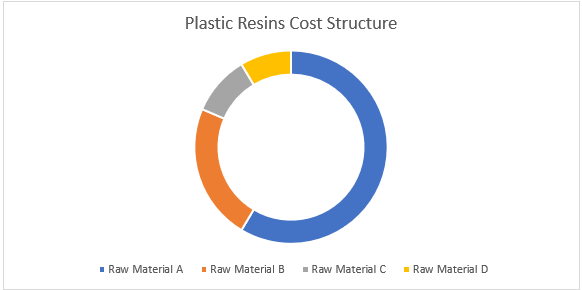

According to the plastic resins procurement report, the cost modeling of plastic resin production is largely influenced by raw material prices, energy consumption, and operational efficiencies. Crude oil and natural gas are key feedstocks for synthetic resins, so fluctuations in their pricing models are a crucial factor. Additionally, costs related to monomers such as ethylene and propylene, which are derived from petrochemical processes, also play a significant role in the plastic resins procurement market.

According to the plastic resins procurement report, energy-intensive production processes like polymerization and extrusion contribute to higher operational costs and pricing strategies. Facilities in regions with high energy prices may experience increased production expenses and pricing strategies. Transitioning to renewable energy sources and adopting energy-efficient technologies could help reduce these costs over time.

Additionally, operational costs, such as labor, maintenance, and adherence to environmental standards, are significant, especially in areas with strict regulatory frameworks. As highlighted in the plastic resins procurement report, plastic resin production costs are heavily influenced by raw material prices, energy usage, negotiation strategies and operational efficiency. Crude oil and natural gas are primary feedstocks for synthetic resins, so their price fluctuations are a key factor. Moreover, the costs of monomers like ethylene and propylene, derived from petrochemical processes, also play a major role in procurement research.

Logistics and transportation expenses are another important cost factor, as resins are typically shipped in bulk to various end-use markets, according to plastic resins sourcing. Furthermore, investments in recycling infrastructure and advanced processing technologies are becoming crucial for the sustainable production of resins.

According to the plastic resins procurement report, the pricing trends of plastic resins are influenced by factors such as feedstock costs, supply-demand balance, and geopolitical influences. In recent years, prices have been volatile due to fluctuations in crude oil markets and disruptions in global supply chains. Strong demand from the packaging, equipment, and healthcare sectors, particularly during the COVID-19 pandemic, has driven prices higher for buyers.

Sustainability trends are reshaping the procurement market, with recycled and bio-based resins commanding higher prices due to increased production costs and limited supply. Price stabilization is expected as innovations in recycling and bio-based technologies become more common, supported by regulatory incentives, pricing strategies, and consumer demand for eco-friendly products.

Efficient sourcing strategies in the plastic resins industry are crucial for managing costs, ensuring supply reliability, and meeting sustainability objectives. Long-term contracts with feedstock suppliers help mitigate raw material price volatility and stabilize costs, according to market research for procurement professionals.

Another key strategy is diversifying supplier networks, which reduces dependence on specific regions and strengthens resilience against potential supply disruptions and pricing models. Companies are increasingly prioritizing suppliers who meet strong environmental compliance standards and hold sustainability certifications, ensuring their operations align with eco-friendly goals, as noted in the plastic resins procurement report.

The use of digital procurement tools and market intelligence platforms has become essential for accurate demand forecasting, cost optimization, negotiation strategies and improved supply chain visibility. Advanced logistics management systems are also employed to streamline transportation and reduce related costs. Additionally, sourcing recycled, or bio-based resins is gaining traction as companies work to meet sustainability targets and regulatory requirements.

Collaborative efforts with suppliers and industry stakeholders are crucial for driving innovation and ensuring the consistent availability and quality of sustainable resin options, contributing to a more sustainable and resilient procurement market.

Founded in 2004 and headquartered in Colombes, France, Arkema specializes in specialty chemicals and plastic resins for automotive, construction, and industrial applications, emphasizing innovation, advanced materials, and sustainable solutions.

Established in 1927 and headquartered in Irving, Texas, Celanese produces high-performance polymers and resins for automotive, healthcare, and consumer goods. As per the plastic resins procurement report, the company is focusing on innovative materials, efficient manufacturing, and environmental sustainability.

Founded in 1802 and headquartered in Wilmington, Delaware, DuPont delivers high-performance plastic resins and materials for automotive, electronics, and industrial sectors, prioritizing innovation, advanced technology, and sustainable product development.

Established in 2001 and headquartered in Essen, Germany, Evonik specializes in specialty chemicals, including polyamides and other plastic resins, serving automotive, consumer goods, and industrial markets with a focus on innovation and sustainability as per the plastic resins procurement report.

Founded in 1978 and headquartered in Taiwan, Formosa Plastics is a global leader in manufacturing PVC, polyethylene, and polypropylene resins, catering to diverse industrial sectors with a commitment to quality and innovation.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

The market was valued at USD 654.13 Billion in 2025.

As per plastic resins procurement report the industry is projected to grow at a CAGR of 2.50% between 2026 and 2031.

The plastic resins market is projected to grow to USD 758.59 Billion by 2031.

The acetic acid production is concentrated in Asia – Pacific particularly in India and China.

The global plastic resins consumption is experiencing significant growth, driven by its widespread applications in increasing demand across various industries, including packaging, automotive, construction, and healthcare.

By product, the market is divided into polyethylene terephthalate (PET), high density polyethylene (HDPE), polyvinyl chloride (PVC), low density polyethylene (LDPE), polypropylene (PP), polystyrene (PS), and others.

The primary raw materials used are crude oil and natural gas.

Procurement best practices in the plastic resins industry include supplier evaluation, quality assurance, regulatory compliance, cost optimisation, sustainable sourcing, risk management, inventory control, long-term contracts, market analysis, and supply chain diversification.

The competitive landscape consists of Arkema S.A., Celanese Corporation, DuPont de Nemours, Inc., Evonik Industries AG, and Formosa Plastics Corporation, among others.

The market is broken down into North America, Europe Middle East and Africa, Asia Pacific, and Latin America.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2031 |

| Growth Rate | CAGR of 2.50 from 2026 to 2031 |

| Regional Cost Structure | Key Cost Indicators, Cost Breakdown by Component |

| Raw Material Market Outlook | Raw Material Market Analysis, Mapping of Key Raw Material Suppliers, Availability of Raw Material by Region, Pricing Outlook of Key Raw Materials |

| Key Sourcing Strategies | Vendor/Supplier Selection, Price and Contract Model Structure, Sourcing Model, Negotiation Strategy |

| Supplier Analysis | Supplier Selection, Key Global Players, Key Regional Players, Supplier Profiles and SWOT Analysis, Innovation and Sustainability |

| Companies Covered | Arkema S.A., Celanese Corporation, DuPont de Nemours, Inc., Evonik Industries AG, and Formosa Plastics Corporation, among others. |

Single User License

One User

USD 4,399

USD 3,959

tax inclusive*

Datasheet

One User

USD 2,999

USD 2,699

tax inclusive*

Five User License

Five User

USD 5,599

USD 4,759

tax inclusive*

Corporate License

Unlimited Users

USD 6,659

USD 5,660

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share