Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The global nylon consumption is gradually increasing, largely due to the fact that the product has very extensive applications in automotive, textile, and electronic industries. This synthetic polymer nylon is mainly applied in the form of fibres, engineering plastics, and films in the manufacture of automotive parts, industrial textiles, and other consumer goods. The nylon procurement report provides insights into the industry's growth dynamics and key factors affecting supply and demand.

Base Year

Historical Period

Forecast Period

The rising demand for light and durable materials in the automotive sector, particularly engine covers, air intake manifolds, and upholstery, is a key driver. As per the nylon procurement report, in the textile industry, nylon fibres are extensively used in clothing and industrial textile materials due to their tensile strength and elasticity. The Asia-Pacific region is one of the major production and consumption regions, with China being a major manufacturer, led by its industrial base and export growth. Market research for procurement professionals plays a crucial role in tracking these industry trends.

Asia-Pacific high production in countries like China and India aims at rising demand by the automotive and textile industries. However, issues such as volatility in raw materials of caprolactam and adipic acid, high energy costs, and stringent environmental norms may impact stability in supply. Strategic purchasing is necessary for managing these supply chain challenges effectively.

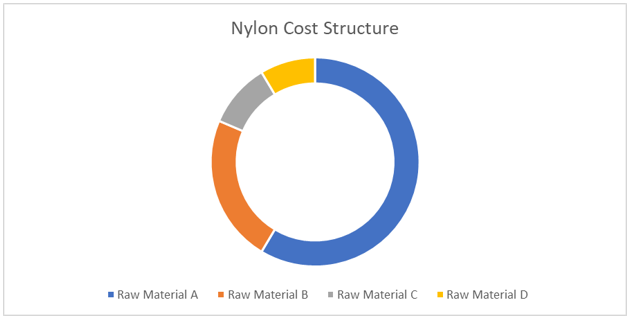

As for the cost structure, raw materials, energy, catalysts, operational expenses, and regulatory compliance are the factors considered in nylon production. As per the nylon procurement report, however, raw materials constitute the largest share of costs for the production process. The main feedstocks for the production of nylon-6 and nylon-6,6 are caprolactam and adipic acid, respectively. The prices of these are linked to crude oil market fluctuations and the benzene derivatives price as well as the price of cyclohexane derivatives. Procurement best practices help mitigate cost fluctuations by securing stable supplier agreements.

Energy costs greatly contribute to cost since nylon production requires energy-intensive processes like polymerisation and spinning. Areas with high energy prices incur higher production costs. Pricing trends in the energy sector directly impact the overall manufacturing cost of nylon.

Additives and catalysts used during polymerisation and stabilisation contribute to the production cost, although improvement in the efficiency of the catalyst has lessened the burden. Operating cost is labor, plant maintenance, and overhead, and automation helps to minimize the inefficiency. Cost modeling assists in breaking down these cost components for better procurement decisions.

Nylon prices are further influenced by shifts in raw material costs, changes in energy, and the demand-supply equations of the international market. This is particularly affected by caprolactam, which is one of the chief feedstocks in nylon-6, and adipic acid used in nylon-6,6. The nylon procurement report states that since it is produced from benzene and cyclohexane, shifts in crude oil market dynamics often affect nylon prices. Pricing strategies help businesses navigate fluctuating costs in the industry.

Recent trends suggest that nylon prices are on the rise due to strong demand from the automotive and textile industries. Supply chain disruptions, including feedstock shortages and increased energy costs, have further exacerbated price pressures. The nylon procurement report highlights how negotiation strategies can be leveraged to counteract price volatility.

As per the nylon procurement market report, stringent environmental regulation, especially in Europe, added to the rise in cost on account of an investment in clean production processes. However, development in recycling technology and increased volume of bio-based nylon is supposed to stabilize long-term prices and capacity expansion in Asia-Pacific tries to meet ever-increasing demand in the globe. Procurement research is essential for tracking these evolving regulatory impacts on the nylon industry.

Procurement in the nylon market focuses on acquiring stable raw material supplies, managing costs, and ensuring sustainability. Long-term contracts with caprolactam and adipic acid suppliers help stabilize the prices due to volatility caused by crude oil and benzene fluctuations. The procurement market for nylon relies on supplier partnerships for cost stability.

As per the nylon procurement report, supplier diversification reduces risks from regional disruptions while sourcing from producers of recycled or bio-based nylon supports sustainability goals. Category management enables businesses to organize their procurement processes efficiently.

Efficient logistics are important because nylon pellets and fibres require secure handling and proximity to markets to minimize costs. Equipment and transportation play a crucial role in cost management and supply chain efficiency.

Digital tools and market intelligence enhance forecasting and cost optimization, ensuring supply chain resilience in a dynamic market. Buyers of nylon benefit from leveraging sourcing strategies to optimize procurement operations. The nylon procurement report provides insights into how businesses can improve procurement efficiency through digital solutions and data analytics.

According to the nylon procurement report, BASF Group, with six segments and 11 operating divisions, leverages its Verbund structure, market-specific strategies, and innovation-driven approach to deliver sustainable solutions and ensure global competitiveness.

Ascend Performance Materials, headquartered in Houston, Texas, USA is a global leader in innovative material solutions, creating safer, sustainable products across industries such as automotive, energy, healthcare, and consumer goods.

Envalior, with over 100 years of expertise and 4,000 global employees, is a trusted engineering materials partner, offering innovative solutions through 18 production sites and 14 R&D centres worldwide, as mentioned in the nylon procurement report.

Koch Industries, based in Wichita, Kansas, is one of America's largest private companies, operating across diverse industries including manufacturing, energy, chemicals, agriculture, and technology. The company has more than 120,000 employees in over 50 countries with an overall revenue of USD 125 billion in 2023.

LIBOLON, is one of the major Asia-Pacific brands specializing in both nylon and polyester, offering comprehensive services from polymerization to post-finishing. Its expertise spans synthetic fibres, engineering plastics, and fabrics, delivering tailored, holistic solutions.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

The nylon market is estimated to be valued at USD 37.15 Billion.

The industry is projected to grow at a CAGR of 5.70% between 2026 and 2031.

The nylon demand is projected to grow to USD 51.81 Billion by 2031.

The nylon production is concentrated in Asia Pacific.

The major drivers of the nylon market include increasing demand from the automotive, textiles, and electronics industries, coupled with advancements in sustainable and recycled nylon production.

By application, the market is divided into automotive, film and coatings, industrial, consumer, electrical and electronics, appliances, wire and cables, and others.

The primary raw materials used are caprolactam and adipic acid.

Procurement best practices in the nylon industry include establishing a flexible and diverse supplier base to mitigate risks associated with raw material price fluctuations. Close collaboration with suppliers and integration of recycled materials into the production process supports both cost efficiency and sustainability efforts.

The competitive landscape consists of BASF SE, Ascend Performance Materials Holdings Inc., Envalior Corporation, Koch, Inc., Libolon Enterprise Co. Ltd., Sarla Performance Fibers Limited., Nylatech Inc., Asahi Kasei Corporation, and Eastex Products, LLC among others.

The market is broken down into North America, Europe, Middle East and Africa, Asia Pacific, and Latin America.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2031 |

| Growth Rate | CAGR of 5.70 from 2026 to 2031 |

| Regional Cost Structure | Key Cost Indicators, Cost Breakdown by Component |

| Raw Material Market Outlook | Raw Material Market Analysis, Mapping of Key Raw Material Suppliers, Availability of Raw Material by Region, Pricing Outlook of Key Raw Materials |

| Key Sourcing Strategies | Vendor/Supplier Selection, Price and Contract Model Structure, Sourcing Model, Negotiation Strategy |

| Supplier Analysis | Supplier Selection, Key Global Players, Key Regional Players, Supplier Profiles and SWOT Analysis, Innovation and Sustainability |

| Companies Covered | BASF SE, Ascend Performance Materials Holdings Inc., Envalior Corporation, Koch, Inc., Libolon Enterprise Co. Ltd., Sarla Performance Fibers Limited., Nylatech Inc., Asahi Kasei Corporation, and Eastex Products, LLC among others. |

Single User License

One User

USD 4,399

USD 3,959

tax inclusive*

Datasheet

One User

USD 2,999

USD 2,699

tax inclusive*

Five User License

Five User

USD 5,599

USD 4,759

tax inclusive*

Corporate License

Unlimited Users

USD 6,659

USD 5,660

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share