Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The global consumption of natural rubber has been growing steadily due to the diverse applications it has in automotive, construction, and medical sectors. Natural rubber, mainly produced from the rubber tree (Hevea brasiliensis), is used to manufacture tires, footwear, industrial products, and medical devices. The natural rubber procurement report indicated the growing demand from these sectors. The primary drivers of demand are in the increase of automobile production, specifically in developing markets of Asia-Pacific, where demand for tires remains on an upward trajectory.

Base Year

Historical Period

Forecast Period

As the automotive industry is rapidly changing to accommodate more electric vehicles, demand for natural rubber tires remains strong because it is highly valued for its robustness, strength, and performance in tires. Natural rubber is also increasing applications in medical supplies, which include gloves and catheters, with the aid of growing global health concerns. The category of medical applications is becoming a crucial part of natural rubber consumption.

As per the natural rubber procurement report, the Asia-Pacific region accounts for the highest share of production and consumption of natural rubber. Thailand, Indonesia, and Malaysia are the primary producers and exporters of natural rubber in the world. These three countries collectively hold a significant share in the global production, while China and India are among the major consumers. The growth of these sectors is driven by expanding industrial activities, especially in the automotive and construction sectors, which require immense quantities of rubber. According to a recent report, procurement practices in these regions are evolving with sustainability initiatives.

On the supply side, fluctuations in weather patterns, especially climate change affecting rubber plantation yields, pose a significant challenge. The rubber tree is sensitive to weather conditions. Droughts, floods, and temperature changes can all have adverse effects on the production of rubber. The natural rubber procurement report further elaborates on these factors.

Labor cost can also be an issue concerning supply stability, as well as the aging of rubber plantations in key producing regions. This industry is also witnessing the increasing demand for sustainable and eco-friendly products. Customers have taken an interest in sustainable rubber sourcing and productive functions. This includes responsible sourcing certifications and the development of alternative sources of natural rubber to reduce dependence on traditional plantations.

As per the natural rubber procurement report, the procurement market for sustainable rubber is expanding as buyers seek ethical sourcing options. While efforts were also focused on diversification of the supply sources—including synthetic rubber alternatives through increased research in this area and innovations in rubber processing technologies—challenges in areas including raw material availability, price, and increasing environmental regulations have continuously been an issue. The industry must, therefore, continually respond to these changes by also incorporating sustainability factors in rubber sourcing, both in environmental and social concerns (such as labor). Procurement research plays a crucial role in identifying emerging trends and best practices.

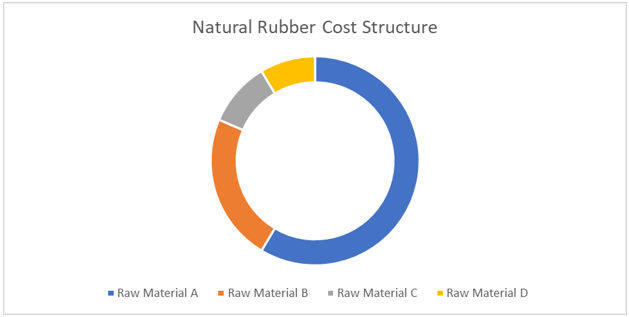

The cost structure of natural rubber production is heavily influenced by a number of factors, including raw materials, energy, labor, operational expenses, and regulatory compliance. Raw materials account for the largest cost component. The principal feedstock for natural rubber is latex obtained from rubber trees (Hevea brasiliensis). The natural rubber procurement report outlines cost modeling techniques for better cost analysis.

Energy costs, though not as dominant as raw material costs, also feature in the cost structure of natural rubber production. Processing raw latex into different rubber products involves energy-intensive steps such as drying, milling, and vulcanization. High energy prices make production costly, especially during the processing stage. The negotiation strategies employed by procurement professionals can help manage energy cost fluctuations effectively.

The natural rubber procurement report highlights that operational costs, including plantation maintenance, rubber processing facilities, and overheads, contribute to the cost of production. Effective management of rubber plantations and processing facilities can maximize yields and minimize the operational cost. Procurement best practices, such as supplier diversification, are crucial in reducing costs. Transportation and distribution costs are key factors; natural rubber is mainly produced in rural areas and needs specialized transport for bulk shipment. The cost of equipment required for harvesting and processing rubber also adds to the overall expenses.

Natural rubber prices are determined by fluctuations in raw material cost, energy, and supply and demand dynamics. The natural rubber procurement report provides insights into pricing trends and factors affecting costs. The natural rubber price closely mirrors the price of raw materials. For example, latex, a product from which rubber is harvested from trees, determines much of the fluctuation in global rubber prices due to climatic factors, crop yield, and world demand for tires. Another factor that affects the price of natural rubber is the price of synthetic rubber, which competes with natural rubber in many applications.

According to the natural rubber procurement report, trends have recently been showing a rise in natural rubber prices due to high demand from the automotive and industrial sectors, mainly in emerging markets in Asia-Pacific, where automobile production and construction activities are expanding. The pricing strategies implemented by major buyers affect how the market reacts to supply fluctuations. Energy costs also are one of the factors that help determine the natural rubber price as the production of rubber products involves energy. According to the natural rubber procurement market report, changes in global fuel prices can make transportation and rubber processing expensive. Market research for procurement professionals helps businesses adapt to these trends.

The procurement practice of the natural rubber industry is a stable source chain managing costs and product quality, all focused on sustainability aspects. The natural rubber procurement report outlines procurement best practices for ensuring a stable supply chain. Long-term contracts signed with rubber producers help to avoid price volatility, especially in key producing regions such as Southeast Asia. Diversifying the sources of supply is another essential strategy. This is achieved through sourcing rubber from different regions: Thailand, Indonesia, Malaysia, and emerging markets in Africa and Latin America.

The category management of procurement operations helps businesses mitigate risks. Concern for sustainability is growing in the procurement of natural rubber. Companies are now focusing their supplies of rubber from suppliers that keep to and apply environmental and social sustainability standards and patterns. Procurement best practices ensure compliance with these sustainability requirements. Other key aspects of procurement include efficient logistics and inventory management. As per the natural rubber procurement report, the procurement market is leveraging digital tools to enhance efficiency. Advanced procurement tools are also progressively used within the natural rubber industry in terms of improving decision-making and managing supply chains.

The use of digital tools for sourcing is transforming the industry. In summary, natural rubber procurement practices focus on securing reliable and sustainable supply chains, optimizing costs, and ensuring product quality. Pricing models and forecasting tools are essential in managing procurement risks. The natural rubber procurement report focuses on the fact that with increasing attention on environmental and social responsibility, companies are focusing on sourcing responsibly produced natural rubber while navigating price volatility and global supply chain challenges.

Established in 1987, Sri Trang is a fully integrated natural rubber company. As per the natural rubber procurement report, the company has large-scale rubber plantations and currently has an area of 7,500 hectares for rubber and other economic crop plantations in 19 provinces of Thailand.

Headquartered in Singapore, the company produces Crumb Rubber and Latex at our processing facilities, in Southeast Asia, China and Africa. The company is supported by a network of logistics assets, storage and terminals, laboratories and sales offices in Southeast Asia, China, South Africa, Europe, United Kingdom and the United States of America.

Established in 1985, the company is a manufacturer and distributor of concentrated latex and other latex products. THAITEX Group consists of 6 factories producing concentrated latex, including other rubber products obtained from the production of latex.

Southland Holdings and its subsidiaries is considered one of the largest infrastructure construction companies in North America. As mentioned in the natural rubber procurement report, founded in 1900, the company has presence in more than 60 countries.

Titi Latex Sdn Bhd, based in Malaysia is specialized in all types of natural rubber processing and production. The company operates a total of five factories in Malaysia and Thailand.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

The natural rubber market is estimated to be valued at USD 32.79 Billion.

The industry is projected to grow at a CAGR of 3.50% between 2026 and 2031.

The natural rubber demand is projected to grow to USD 40.31 Billion by 2031.

Natural rubber production is concentrated in Asia Pacific.

The natural rubber market is being driven by the increasing demand for tyres as well as latex goods like gloves, belts, catheters, condoms, and other industrial durables, among others.

RSS grade, latex concentrate, and solid block rubber, among others are the various types of natural rubber in the market.

The rising demand from emerging economies for natural rubber and the increasing demand for tyres as well as latex goods are the key trends leading the market’s expansion.

The major players in the market are Sri Trang Agro-Industry Public Company Limited, Halcyon Agri Corporation Limited, Thai Rubber Latex Group Public Company Limited, Southland Holding Company, Titi Latex Sdn Bhd, KL-Kepong Rubber Products Sdn, Von Bundit Co., Ltd., Sinochem International Corporation, and WEBER & SCHAER GmbH & Co. KG, among others.

The best procurement practices in the natural rubber industry involve ensuring transparent pricing, promoting sustainable sourcing, and adopting quality control measures to guarantee consistency and traceability.

The industry is broken down into North America, Europe, Middle East and Africa, Asia Pacific, and Latin America.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2031 |

| Growth Rate | CAGR of 3.50 from 2026 to 2031 |

| Regional Cost Structure | Key Cost Indicators, Cost Breakdown by Component |

| Raw Material Market Outlook | Raw Material Market Analysis, Mapping of Key Raw Material Suppliers, Availability of Raw Material by Region, Pricing Outlook of Key Raw Materials |

| Key Sourcing Strategies | Vendor/Supplier Selection, Price and Contract Model Structure, Sourcing Model, Negotiation Strategy |

| Supplier Analysis | Supplier Selection, Key Global Players, Key Regional Players, Supplier Profiles and SWOT Analysis, Innovation and Sustainability |

| Companies Covered | Sri Trang Agro-Industry Public Company Limited, Halcyon Agri Corporation Limited, Thai Rubber Latex Group Public Company Limited, Southland Holding Company, Titi Latex Sdn Bhd, KL-Kepong Rubber Products Sdn, Von Bundit Co., Ltd., Sinochem International Corporation, and WEBER & SCHAER GmbH & Co. KG, among others. |

Single User License

One User

USD 4,399

USD 3,959

tax inclusive*

Datasheet

One User

USD 2,999

USD 2,699

tax inclusive*

Five User License

Five User

USD 5,599

USD 4,759

tax inclusive*

Corporate License

Unlimited Users

USD 6,659

USD 5,660

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share