Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

According to the high-density polyethylene (HDPE) procurement report, the demand for HDPE is driven by its extensive use in industries like packaging, construction, automotive, and healthcare, due to its strength, durability, and recyclability. Increasing demand from buyers for sustainable, lightweight, and cost-effective materials in packaging, especially for bottles, containers, and films, is also pushing HDPE pricing strategies.

Base Year

Historical Period

Forecast Period

According to procurement sourcing, its use in piping systems, as well as in the automotive and construction sectors for services such as insulation and geomembranes, continues to increase. The demand for environmentally friendly products and the growth of recycling infrastructure also plays a role in HDPE's category management.

According to the high-density polyethylene (HDPE) procurement market report, HDPE is the third-largest commodity plastic material globally, following polyvinyl chloride (PVC) and polypropylene. High-density polyethylene (HDPE) procurement sourcing is experiencing growth, with both supply and category demand expected to rise significantly during the forecast period.

Asia, especially China, will remain the primary driver of this demand. Northeast Asia alone is projected to account for over one-third of global consumption by 2027. The high-density polyethylene (HDPE) procurement report also notes that HDPE makes up about 45% of China’s total polyethylene demand, which is estimated at 38.9 million tonnes in 2023.

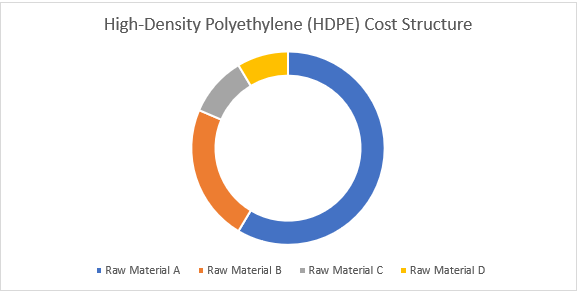

According to the high-density polyethylene (HDPE) procurement report, the cost modeling of HDPE is influenced by several key factors, including the price of raw materials, mainly ethylene, which is derived from natural gas or petroleum. Changes in crude oil and natural gas prices directly impact the pricing trends of ethylene production, which in turn affects HDPE negotiation strategies. The polymerization process, which requires catalysts and energy-intensive equipment, also plays a role in shaping overall pricing strategies.

According to the high-density polyethylene (HDPE) procurement market, labor and operational costs, including those related to plant maintenance and safety, are additional factors influencing pricing stategies. Additionally, transportation costs are crucial in category management, as HDPE is often produced in large quantities and needs to be efficiently distributed to global markets.

Environmental regulations, compliance with recycling standards, and increasing investments in sustainable production technologies are becoming essential components of cost modeling, as outlined in the high-density polyethylene (HDPE) procurement report. Lastly, market dynamics, such as demand from key sectors like packaging, construction, and automotive, as well as competition among manufacturers, can further affect the strategic purchasing of HDPE.

According to the high-density polyethylene (HDPE) procurement report, pricing models are primarily influenced by fluctuations in raw material costs, particularly ethylene. Negotiation strategies are also affected by supply chain disruptions, geopolitical factors, and changes in energy costs, leading to periods of volatility. As demand from key sectors such as packaging, construction, and automotive continues to grow, especially in emerging markets like Asia, HDPE cost modeling is impacted.

Furthermore, the increasing emphasis on sustainability and recycling has led to investments in more eco-friendly production methods, which can sometimes raise production costs, as noted in market research for procurement professionals. Overall, HDPE sourcing prices have followed an upward trend in response to rising demand and higher production costs, although they remain sensitive to global economic conditions, strategic purchasing and raw material availability.

According to the high-density polyethylene (HDPE) procurement report, sourcing practices involve category management from trusted suppliers who can meet quality, cost, pricing trends and delivery requirements. Companies typically enter long-term contracts to ensure stable pricing strategies and secure supply, especially considering HDPE's widespread use in industries like packaging, construction, and automotive equipment.

Logistics play a critical role, as HDPE is produced in bulk and requires efficient transportation and storage. Additionally, companies may prioritize suppliers who offer sustainability options, such as recycled HDPE, in response to the increasing demand for eco-friendly materials, as outlined in the high-density polyethylene (HDPE) procurement report. To mitigate risks from supply chain disruptions, companies often diversify their strategic purchasing practices for buyers.

INEOS Group, founded in 1998 and headquartered in London, the United Kingdom, is a global manufacturer of petrochemicals, specialty chemicals, and oil products. As per the high-density polyethylene (HDPE) procurement report, the company is made up of 36 individual businesses and operates 194 facilities in 29 countries across the globe.

LyondellBasell Industries N.V. headquartered in the Netherlands is engaged in the manufacture and sale of plastics, petrochemicals, and basic chemicals. The compnay operates in major markets including the United States, Argentina,Hong Kong, China, India, and Brazil.

ExxonMobil was incorporated in 1882 and has around 62,000 employees. In 2023, its earnings stood at USD 36 billion. It is one of the largest publicly traded energy providers and chemical manufacturers in the world. According to the high-density polyethylene (HDPE) procurement report, the company develops and applies next-generation technologies to meet the world’s rising needs for energy and high-quality chemical products.

Dow is a leading materials science company, serving customers in high-growth markets such as packaging, infrastructure, and consumer applications. The company operates in around 31 countries in the world.

Braskem is a global company with industrial units located in the United States, Brazil, Mexico, Europe, and Asia. It was founded in 2002 via the integration of six companies from the Odebrecht Organization and the Mariani Group.With customers in over 71 countries, Braskem is a market leader in the Americas and a significant producer of biopolymers on an industrial scale.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

The market was valued at USD 83.27 Billion in 2025.

As per high-density polyethylene (HDPE) procurement report the industry is projected to grow at a CAGR of 4.70% between 2026 and 2031.

The high-density polyethylene (HDPE) market is projected to grow to USD 109.69 Billion by 2031.

The global high-density polyethylene (HDPE) consumption is driven by the increasing demand from industries such as packaging, construction, and automotive due to HDPE's durability and versatility. Additionally, the rising emphasis on sustainable and recyclable materials aids the market.

By application, the market is divided into film and sheet, injection moulding, blow moulding, pipe and profile, wire and cables, and others.

The primary raw material for high-density polyethylene (HDPE) is ethene (ethylene), a hydrocarbon derived from natural gas or petroleum.

The competitive landscape consists of INEOS Group, LyondellBasell Industries Holdings B.V., Exxon Mobil Corporation, The Dow Chemical Company, Braskem SA, Formosa Plastics Corporation, Reliance Industries Limited, TotalEnergies SE, Borealis AG, and Chevron Phillips Chemical Company LLC, among others.

Procurement best practices in the high-density polyethylene (HDPE) industry include securing long-term contracts with key suppliers, leveraging economies of scale to reduce costs, and implementing robust supply chain monitoring to address potential disruptions.

The market is broken down into North America, Latin America, EMEA, APAC.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2031 |

| Growth Rate | CAGR of 4.70 from 2026 to 2031 |

| Regional Cost Structure | Key Cost Indicators, Cost Breakdown by Component |

| Raw Material Market Outlook | Raw Material Market Analysis, Mapping of Key Raw Material Suppliers, Availability of Raw Material by Region, Pricing Outlook of Key Raw Materials |

| Key Sourcing Strategies | Vendor/Supplier Selection, Price and Contract Model Structure, Sourcing Model, Negotiation Strategy |

| Supplier Analysis | Supplier Selection, Key Global Players, Key Regional Players, Supplier Profiles and SWOT Analysis, Innovation and Sustainability |

| Companies Covered | INEOS Group, LyondellBasell Industries Holdings B.V., Exxon Mobil Corporation, The Dow Chemical Company, Braskem SA, Formosa Plastics Corporation, Reliance Industries Limited, TotalEnergies SE, Borealis AG, and Chevron Phillips Chemical Company LLC, among others. |

Datasheet

One User

USD 2,999

USD 2,699

tax inclusive*

Single User License

One User

USD 4,399

USD 3,959

tax inclusive*

Five User License

Five User

USD 5,599

USD 4,759

tax inclusive*

Corporate License

Unlimited Users

USD 6,659

USD 5,660

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share