Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The construction and building industry is the major user of ethylene tetrafluoroethylene (ETFE). In architectural applications, it provides a lightweight alternative to glass. Its growing demand is because of its outstanding features such as high light transmission, durability, and resistance to weather. The increasing use of ethylene tetrafluoroethylene (ETFE) in the renewable energy sector, especially in solar panels, is attributed to its self-cleaning properties and excellent light transmission.

Base Year

Historical Period

Forecast Period

ETF has gained wide usage in the automotive and aerospace industries for parts demanding high chemical resistance and thermal stability. The ethylene tetrafluoroethylene (ETFE) procurement report also underlines the increasing usage of the material in high-tech greenhouses for controlled agriculture, especially in areas focused on food security and all-year crop production.

The current leader as per the ethylene tetrafluoroethylene (ETFE) procurement report market is North America, dominating both production and consumption due to strong demand from the construction, automotive, aerospace, and electronics industries. Its mature construction sector, emphasis on sustainable building practices, and the growing adoption of renewable energy sources have significantly contributed to its market dominance. Asia-Pacific is emerging as a significant competitor with the fastest growth rate in the ETFE market due to rapid industrialization, infrastructure development, and increasing investment across end-use industries, primarily in China, Japan, and India.

On the supply side, the ethylene tetrafluoroethylene (ETFE) procurement report shows that there is a high growth rate on the supply side due to strategic efforts by leading manufacturers. Some of the top companies in the ETFE market, such as Vector Foiltec GmbH, are actively expanding production capacity in Germany to meet the rising demand.

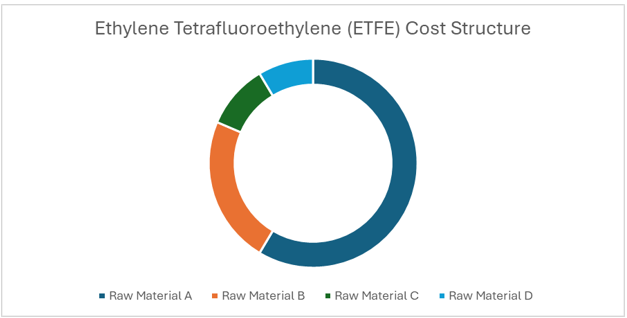

The pricing models of ethylene tetrafluoroethylene (ETFE) production is dominated by key factors such as raw materials, energy, operational costs, and regulatory compliance. The ethylene tetrafluoroethylene (ETFE) procurement category has a raw material price structure significantly depending on ethylene and tetrafluoroethylene (TFE) monomers, which under free-radical polymerization, are done in a solvent or hybrid media, using organic peroxide initiators. Volatile pricing of crude oil has direct impacts on manufacturing costs for ETFE as evident in the recent pandemic, during which increased prices of oil also impacted ETFE pricing and manufacturers' revenues.

Energy costs play a significant role in affecting the cost structure of ETFE, through its manufacturing process and operational requirements. Although ETFE is manufactured using a water-based process that requires almost negligible amounts of energy during extrusion, such complex manufacturing with various equipment and specialized expertise may be time-consuming and expensive to yield.

As per ethylene tetrafluoroethylene (ETFE) procurement report, the operational cost for ETFE is much lower compared to most conventional building materials because of several key points. The self-cleaning nature of the material reduces the requirement for its maintenance and hence brings down the costs of regular cleaning processes. A substantially lesser energy expense due to material insulation and its properties of increased transparency leads to superior energy efficiency; it's 30 percent saved on artificial light usage plus higher thermal effectiveness. The thin structure of the ETFE also economizes on additional supports and less requirements for heavy foundations.

Environmental regulations and compliance costs are highly significant for ETFE. An advanced manufacturing process, special materials, and expert knowledge cause high production costs. The ethylene tetrafluoroethylene (ETFE) procurement report indicates a further increase in the cost burden due to strict EPA regulations. ETFE enjoys benefits of sustainability through recyclability and reprocessing but is yet to be supported by a proper infrastructure of recycling and reuse of the material. Volatility in raw material prices worsens the challenges in costs.

Ethylene tetrafluoroethylene (ETFE) price conditions are highly influenced by raw material costs, the complexity of manufacturing, and the demand in the market. Production costs are rather high at first due to complicated manufacturing processes and special materials involved. The variation in crude oil prices during world events such as the COVID-19 pandemic impacts ETFE price. The ethylene tetrafluoroethylene (ETFE) procurement market report highlights that although ETFE is more expensive than other materials, it often pays back through its longevity and energy-saving capabilities. The material price differs regionally. Asia-Pacific tends to be the most competitive market because of cheaper labor and more readily available raw materials. Cost optimization through improved procurement strategies and inventory management by manufacturers will continue to help sustain pricing competitiveness.

According to the ethylene tetrafluoroethylene (ETFE) procurement report, ethylene tetrafluoroethylene (ETFE) procurement is a planned activity since the material is specific and has few suppliers. The ethylene tetrafluoroethylene (ETFE) procurement category involves the establishment of long-term partnerships with major manufacturers such as AGC, Daikin, and Saint-Gobain in ETFE markets to ensure consistent supply and competitive prices. Suppliers are evaluated according to their manufacturing capabilities, quality certifications, and technical support services when procuring ETFE.

Cost optimization is further achieved through bulk purchasing agreements and timing purchases at periods of stable raw material prices. Early engagement with suppliers is important for construction projects because this can help build availability and custom specifications for the material. Strategic purchasing plays a crucial role in securing favorable terms and ensuring supply chain resilience. Procurement teams also focus on the suppliers with good research and development capabilities, ensuring access to innovative ETFE solutions and improvements in technical components.

Market research for procurement professionals is essential in analyzing supplier landscapes, pricing trends, and emerging ETFE technologies. This enables procurement teams to make informed decisions, optimize costs, and stay ahead of industry advancements.

BASF SE was founded in 1865 and is headquartered in Germany. As per the ethylene tetrafluoroethylene (ETFE) procurement report, the company specialises in chemicals, materials, industrial solutions, surface technologies, nutrition, and agricultural solutions, and has a workforce of over 110,000 employees across six integrated production sites worldwide.

AGC Group was established in 1907 and is headquartered in Tokyo, Japan. The company leads in glass, electronics, chemicals, and ceramics, and operates in more than 30 countries with innovative solutions for architectural, automotive, and display applications.

Solvey SA was founded in 1863 and is headquartered in Belgium. The ethylene tetrafluoroethylene (ETFE) procurement report states that the company operates in more than 64 countries with a workforce of over 21,000 employees, and specialises in sustainable solutions for automotive, aerospace, and electronics industries.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

The ethylene tetrafluoroethylene (ETFE) market is estimated to be valued at USD 433.63 Billion.

The industry is projected to grow at a CAGR of 8.30% between 2026 and 2031.

The ethylene tetrafluoroethylene (ETFE) market is projected to grow to USD 699.66 Billion by 2031.

The ethylene tetrafluoroethylene (ETFE) production is concentrated in North America, particularly in the United States.

The global ethylene tetrafluoroethylene (ETFE) consumption is experiencing significant growth, driven by growing demand in construction and automotive sectors, increasing adoption in solar panels, rising need for lightweight materials, and expanding applications in aerospace and electronics industries.

By application, the market is divided into films and sheets, wires and cables, tubes, coatings, and others.

The primary raw materials used are ethylene and tetrafluoroethylene (TFE) monomers.

The ETFE industry employs strategic sourcing, competitive bidding, and supplier relationship management as key procurement practices. Companies focus on spend analysis, risk management, and leveraging technology for process automation. Sustainable sourcing and ongoing supplier evaluation are also prioritized to ensure quality and cost-effectiveness.

The competitive landscape consists of BASF SE, AGC Group, Solvey SA, Daikin Industries, Ltd., 3M Co., Hubei Everflon Polymer Co. Ltd, HaloPolymer OJSC, Mitsubishi Chemical Group Corp, Vector Foiltec, Saint-Gobain Composite Solutions among others.

As per the ethylene tetrafluoroethylene (ETFE) procurement report, the market is broken down into North America, Europe Middle East and Africa, Asia Pacific, and Latin America.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2031 |

| Growth Rate | CAGR of 8.30 from 2026 to 2031 |

| Regional Cost Structure | Key Cost Indicators, Cost Breakdown by Component |

| Raw Material Market Outlook | Raw Material Market Analysis, Mapping of Key Raw Material Suppliers, Availability of Raw Material by Region, Pricing Outlook of Key Raw Materials |

| Key Sourcing Strategies | Vendor/Supplier Selection, Price and Contract Model Structure, Sourcing Model, Negotiation Strategy |

| Supplier Analysis | Supplier Selection, Key Global Players, Key Regional Players, Supplier Profiles and SWOT Analysis, Innovation and Sustainability |

| Companies Covered | BASF SE, AGC Group, Solvey SA, Daikin Industries, Ltd., 3M Co., Hubei Everflon Polymer Co. Ltd, HaloPolymer OJSC, Mitsubishi Chemical Group Corp, Vector Foiltec, Saint-Gobain Composite Solutions among others. |

Datasheet

One User

USD 2,999

USD 2,699

tax inclusive*

Single User License

One User

USD 4,399

USD 3,959

tax inclusive*

Five User License

Five User

USD 5,599

USD 4,759

tax inclusive*

Corporate License

Unlimited Users

USD 6,659

USD 5,660

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share