Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The global carbon black consumption is experiencing substantial growth, primarily fuelled by its widespread use in industries such as automotive, rubber, coatings, paper, and electronics. Carbon black, a fine black powder produced from the incomplete combustion of hydrocarbons, is predominantly used as a reinforcing agent in rubber products, especially in tyres, and as a pigment in coatings, inks, and plastics.

Base Year

Historical Period

Forecast Period

Key drivers of carbon black procurement report include the substantial growth in automotive production, the rising demand for high-performance tyres, and the growing electronics industry, where carbon black is used for conductive and anti-static properties. With the growth in the electric vehicle industry, the demand of high-performance tyres is expected to increase significantly globally as the weight of the overall vehicle is considerably higher of the EV as compared to an IC engine car of a similar specification.

Regionally, Asia-Pacific is the largest consumer of carbon black, with key markets including China, India, South Korea, and Japan. North America and Europe follow, with strong demand driven by automotive and industrial applications. In terms of production, Asia-Pacific leads the carbon black procurement market report, followed by North America and Europe, with China being a major contributor to both production and consumption.

On the supply side, technological advancements in production processes, such as improved furnace black production methods, are helping to meet the growing demand for carbon black. However, challenges such as volatile raw material prices, environmental regulations, and the need for sustainable production practices may impact the dynamics of carbon black procurement report moving forward.

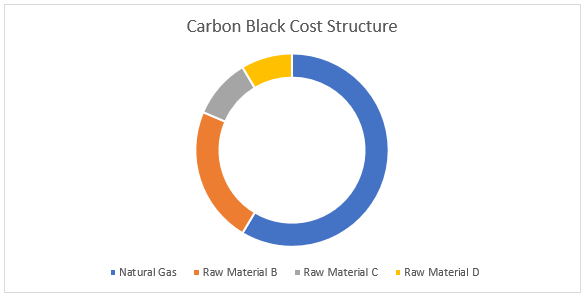

The cost modeling of carbon black is influenced by multiple factors, primarily its feedstock, production process, and market demand. Carbon black is manufactured via processes like the furnace black or thermal black method, both of which rely on hydrocarbons such as oil or natural gas as raw materials. Fluctuations in crude oil and natural gas prices significantly affect feedstock costs, which constitute a major portion of the overall expense. Energy-intensive production processes further add to operating costs, making energy prices another critical component of the cost structure.

As per the carbon black procurement report, production efficiency, plant location, and economies of scale also play pivotal roles in the overall cost of the product. Plants located near feedstock sources or key markets can reduce logistical expenses, while larger facilities benefit from reduced per-unit production costs. Regulatory compliance, including environmental restrictions on emissions, adds to production costs, as companies invest in technologies to minimize environmental impact.

Downstream market demand influences profitability and pricing strategies. Industries like tyre manufacturing, which require specific carbon black grades, affect cost dynamics through their volume and quality requirements. Specialized grades, such as conductive or high-structure types, often carry higher production costs due to stricter specifications. Transportation and distribution expenses further shape the final pricing models, particularly for export markets requiring long-distance shipping.

Advancements in production technologies and more sustainable manufacturing practices could shift the cost structure by improving energy efficiency and reducing environmental compliance costs, further affecting the competitive landscape in the carbon black procurement report.

Carbon black pricing models are primarily driven by the cost of raw materials, such as oil, natural gas, and coal, with fluctuations in these commodities impacting production expenses. Energy costs also play a significant role, as the manufacturing process requires substantial heat to achieve high temperatures. Demand from key industries like automotive, rubber, and electronics has been rising, particularly in regions such as Asia-Pacific contributing to price increases. Additionally, supply chain disruptions, higher energy prices, and stricter environmental regulations have added pressure to prices. However, advancements in production technologies and expanded capacity in major markets are expected to provide some price stability over time.

Carbon black procurement focuses on securing a consistent supply of this vital material, used primarily in reinforcing rubber, and improving conductivity in applications like tyres, plastics, and coatings. Key technical parameters in carbon black procurement report such as particle size, surface area (BET values), structure (DBP absorption), and tint strength are critical considerations to ensure optimal performance in specific applications. As a by-product of the incomplete combustion of hydrocarbons, its pricing strategies is heavily influenced by crude oil and natural gas markets, requiring vigilant cost management and category management. Buyers prioritize sourcing from reliable producers offering grades tailored for specific uses, such as N-series grades for rubber reinforcement or specialized conductive grades for electronics. Sustainability goals are prompting interest in recycled and bio-based carbon black. Additionally, strategic sourcing, logistics optimization, and supplier diversification are essential practices to mitigate risks and ensure supply continuity.

The company was founded in 1857 and headquartered in Mumbai, India. Aditya Birla Group is a global conglomerate with a strong presence in the carbon black industry. According to the carbon black procurement report, the company operates through its subsidiary, Aditya Birla Chemicals, catering to industries like automotive, rubber, and plastics.

Founded in 1882 and headquartered in Boston, Massachusetts, USA, Cabot Corporation is a leading global producer of specialty chemicals, including carbon black. The company focuses on high-performance products and sustainability, especially in automotive and industrial sectors.

The company was established in 1936 and headquartered in Houston, Texas, United States. Continental Carbon is a prominent supplier of carbon black for industries such as tire manufacturing and coatings. The company is known for its advanced manufacturing processes and sustainable production.

It was founded in 1862 and headquartered in Luxembourg. Orion Engineered Carbons is a leading global supplier of carbon black for industries like automotive, coatings, and rubber. The company is committed to innovation and sustainability in production processes.

Established in 1960 and headquartered in Kolkata, India, PCBL Chemical is a significant player in the global carbon black procurement report. The company supplies various carbon black grades to industries like tires, rubber, and plastics.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

The global carbon black market size stood at a value of around USD 17.82 Billion in 2024.

The industry is projected to grow at a CAGR of 7.20% between 2025 and 2030.

The carbon black procurement market is projected to grow to USD 27.04 Billion by 2030.

The carbon black production is concentrated in Asia Pacific.

The global carbon black market is growing due to its use in industries such as automotive, rubber, coatings, and electronics. The increasing demand for high-performance tyres and durable rubber products is driving this growth.

By grade, the market is divided into speciality carbon black and rubber carbon black.

The primary raw materials used in the production of carbon black are hydrocarbons such as oil, natural gas, and coal. These materials undergo incomplete combustion in the manufacturing process to produce carbon black.

Procurement best practices in the carbon black industry include assessing particle quality, prioritizing local sourcing, analysing cost-impact of energy inputs, managing vendor relationships for large-volume orders, and monitoring regulatory changes.

The competitive landscape of the carbon black procurement report consists of Aditya Birla Group, Cabot Corporation, Continental Carbon Company, Orion Engineered Carbons S.A., PCBL Chemical Limited, Mitsubishi Chemical Group, Jiangxi Black Cat Carbon Black Co., Ltd., Tokai Carbon Co., Ltd., Longxing Chemical Stock Co., Ltd., Omsk Carbon Group, and Imerys S.A., among others.

The market is broken down into North America, Latin America, EMEA, and APAC.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2030 |

| Growth Rate | CAGR of 7.20 from 2025 to 2030 |

| Regional Cost Structure | Key Cost Indicators, Cost Breakdown by Component |

| Raw Material Market Outlook | Raw Material Market Analysis, Mapping of Key Raw Material Suppliers, Availability of Raw Material by Region, Pricing Outlook of Key Raw Materials |

| Key Sourcing Strategies | Vendor/Supplier Selection, Price and Contract Model Structure, Sourcing Model, Negotiation Strategy |

| Supplier Analysis | Supplier Selection, Key Global Players, Key Regional Players, Supplier Profiles and SWOT Analysis, Innovation and Sustainability |

| Companies Covered | Aditya Birla Group, Cabot Corporation, Continental Carbon Company, Orion Engineered Carbons S.A., PCBL Chemical Limited, Mitsubishi Chemical Group, Jiangxi Black Cat Carbon Black Co., Ltd., Tokai Carbon Co., Ltd., Longxing Chemical Stock Co., Ltd., Omsk Carbon Group, and Imerys S.A., among others. |

Datasheet

One User

USD 2,999

USD 2,699

tax inclusive*

Single User License

One User

USD 4,399

USD 3,959

tax inclusive*

Five User License

Five User

USD 5,599

USD 4,759

tax inclusive*

Corporate License

Unlimited Users

USD 6,659

USD 5,660

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Our step-by-step guide will help you select, purchase, and access your reports swiftly, ensuring you get the information that drives your decisions, right when you need it.

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City,1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

United States

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

United States (Head Office)

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City, 1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

Share