Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The global acrylic acid consumption is experiencing steady growth, driven by its wide range of applications in industries such as paints and coatings, superabsorbent polymers (SAPs), plastics, and adhesives. Acrylic acid is primarily used in the production of acrylate esters (used in paints, coatings, and adhesives) and superabsorbent polymers (used in personal hygiene products like diapers).

Base Year

Historical Period

Forecast Period

Key drivers of acrylic acid procurement report include the growing e-commerce sector, which boosts demand for packaging materials and coatings, and the increasing use of superabsorbent polymers in hygiene products due to population growth and rising living standards, particularly in emerging regions. Additionally, strong demand from the construction and automotive industries, where acrylic acid is used in coatings and adhesives, is contributing to demand growth. The Asia-Pacific region, particularly China and India, leads both in production and consumption, driven by their rapidly expanding manufacturing sectors and large consumer sectors.

The supply side in acrylic acid procurement report is seeing increased investments in production capacity, especially in regions like Asia-Pacific and the Middle East, to meet rising demand. However, supply stability faces challenges due to raw material availability—especially for propylene, which is the main feedstock for acrylic acid production—and energy costs. Furthermore, environmental regulations in key regions, such as stricter emissions controls, are influencing production processes, adding cost pressures. The ongoing focus on bio-based acrylic acid production and sustainable manufacturing practices is helping address sustainability concerns, reduce dependency on fossil resources, and diversify supply sources.

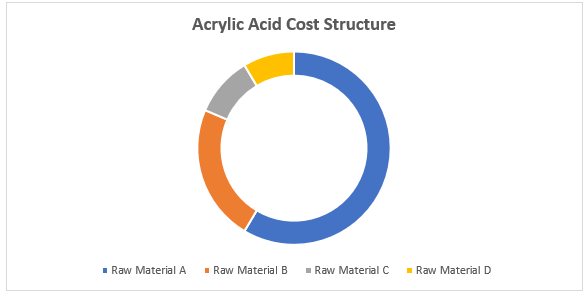

The cost modeling of acrylic acid production is influenced by key factors, including raw materials, energy costs, catalysts, operational expenses, and regulatory compliance. Raw materials, particularly propylene, represent the largest component of production costs. Propylene, a byproduct of petroleum refining and natural gas processing, is subject to price fluctuations driven by crude oil and natural gas industry dynamics. The availability and cost of acetic acid, another key feedstock, also affect production expenses.

As per acrylic acid procurement report, energy cost modeling play a significant role in acrylic acid production, as the process requires high temperatures for the dehydration of propylene. Energy-intensive steps, such as steam cracking and oxidation, make production sensitive to rising energy prices, particularly in regions with higher electricity and natural gas costs. In areas with elevated energy prices, production costs can be substantially higher.

Catalysts, including silver-based catalysts used in the oxidation of propylene to acrylic acid, also contribute to costs. Although these catalysts are highly effective and long-lasting, their initial cost and the need for periodic replenishment can add to overall production expenses.

Operational costs, including labor, plant maintenance, and overheads, are another important consideration in acrylic acid procurement report. Optimizing plant efficiency through automation and lean manufacturing practices can help mitigate these costs. Additionally, the proximity of production facilities to raw material sourcing and end-use sectors affects transportation and distribution expenses, particularly since acrylic acid is often shipped in bulk to industries such as coatings, adhesives, and plastics.

Acrylic acid pricing models are influenced by fluctuations in raw material costs, energy prices, and supply-demand dynamics. The primary feedstocks for acrylic acid production are propylene and acetic acid, with propylene being the key determinant. As propylene is derived from crude oil and natural gas, its price is highly sensitive to volatility in global oil and gas sectors. Recent pricing trends in acrylic acid procurement report show rising prices driven by robust demand from industries such as superabsorbent polymers (SAPs), paints and coatings, and adhesives, especially in the Asia-Pacific region, where industrial growth is strong.

Price increases have been further exacerbated by supply chain disruptions, including raw material shortages and logistical challenges. Additionally, rising energy costs, driven by fluctuations in natural gas and electricity prices, have contributed to higher production expenses for acrylic acid manufacturers. Moreover, compliance with increasingly stringent environmental regulations around emissions and waste disposal has added to the cost burden for producers in regions with tight environmental controls.

Procurement practices in the acrylic acid procurement report are centered around securing consistent, cost-effective, and high-quality raw materials while navigating price volatility and aligning with sustainability goals. Key strategies include establishing long-term contracts with suppliers of propylene and acetic acid, the primary feedstocks, to mitigate the impact of price fluctuations. Supplier diversification is crucial to reduce dependency on specific regions and ensure a steady supply amid global supply chain disruptions. Additionally, a strong emphasis is placed on sourcing from suppliers with strong environmental compliance, as the industry faces increasing regulatory pressure to reduce its environmental footprint.

As per acrylic acid procurement report, efficient logistics and inventory management are vital to ensure the timely and secure delivery of raw materials, as acrylic acid production requires precise coordination between multiple stages of the supply chain. With the increasing complexity of global logistics, advanced digital tools and real-time tracking are becoming integral for optimizing procurement operations, enabling better forecasting, and minimizing the risk of stockouts or excess inventory.

As the acrylic acid industry shifts toward more sustainable production methods, including bio-based production technologies and renewable feedstocks, procurement practices are evolving. Suppliers with capabilities in bio-based materials or energy-efficient production processes are becoming increasingly important. These sustainable procurement and pricing strategies not only align with corporate sustainability objectives but also help reduce reliance on fossil resources, improving cost efficiency and environmental impact over the long term.

BASF offers glacial acrylic acid for manufacturing polymers and for use as a feedstock for syntheses. BASF SE, popularly known as the BASF group, is a global frontrunner in the chemical industry, boasting a massive workforce of over 111,000 employees across the globe.

Founded in 1941, is a renowned chemical manufacturing company, offering unique catalyst technologies such as ethylene oxide, acrylic acid, automobile catalyst, process catalyst. As per the acrylic acid procurement report, the products offered by the company finds application in building and construction, electronics, daily use materials, inks and coatings, among others.

With manufacturing facilities spread across 31 countries, Dow employs around 37,800 individuals. Founded in 1897, the company offers glacial acrylic acid which finds use as a chemical intermediate.

As per the acrylic acid procurement report, the company offers products and solutions of specialty materials under three groups which are: adhesive solutions, advanced materials, and coating solutions. Founded in 2006, company offers solutions for various applications such as electric batteries, mass 3D printing, sustainable construction and energy-efficient transport.

LG Chem is a leading global chemical company founded in 1947. The company has a diversified business portfolio in the key areas of petrochemicals, advanced materials, and life sciences. LG Chem is considered Korea's only acrylic acid manufacturer, producing high-quality products based on its proprietary technology.

*Please note that this is only a partial list; the complete list of key players is available in the full report. Additionally, the list of key players can be customized to better suit your needs.*

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

The global acrylic acid procurement report attained a volume of approximately 8.87 MMT in 2025.

The demand is projected to grow at a CAGR of 5.10% between 2026 and 2031.

The acrylic acid procurement market report is expected to reach a volume of around 11.95 MMT by 2031.

The demand is driven by the growth of construction, superabsorbent polymers, and automobile industries, and increasing population.

The leading applications of acrylic acid are acrylate esters, and super absorbent polymer (SAP), among others.

Acrylic acid is produced from propylene, a gaseous product of oil refineries.

The major players are BASF SE, Nippon Shokubai Co. Ltd., The Dow Chemical Company, Arkema Group, LG Chem. Ltd., Shanghai Huayi Acrylic Acid Co., Ltd, Evonik Industries AG, Mitsubishi Chemical Corporation, SIBUR International GmbH, Satellite Chemical Co., Ltd., Wanhua Petrochemical (Yantai) Co., Ltd., Toagosei Co., Ltd, and China Petroleum & Chemical Corporation, among others.

The acrylic acid procurement market report is broken down into North America, Europe Middle East and Africa, Asia Pacific, and Latin America.

Explore our key highlights of the report and gain a concise overview of key findings, trends, and actionable insights that will empower your strategic decisions.

| REPORT FEATURES | DETAILS |

| Base Year | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2031 |

| Growth Rate | CAGR of 5.10 from 2026 to 2031 |

| Regional Cost Structure | Key Cost Indicators, Cost Breakdown by Component |

| Raw Material Market Outlook | Raw Material Market Analysis, Mapping of Key Raw Material Suppliers, Availability of Raw Material by Region, Pricing Outlook of Key Raw Materials |

| Key Sourcing Strategies | Vendor/Supplier Selection, Price and Contract Model Structure, Sourcing Model, Negotiation Strategy |

| Supplier Analysis | Supplier Selection, Key Global Players, Key Regional Players, Supplier Profiles and SWOT Analysis, Innovation and Sustainability |

| Companies Covered | BASF SE, Nippon Shokubai Co. Ltd., The Dow Chemical Company, Arkema Group, LG Chem. Ltd., Shanghai Huayi Acrylic Acid Co., Ltd, Evonik Industries AG, Mitsubishi Chemical Corporation, SIBUR International GmbH, Satellite Chemical Co., Ltd., Wanhua Petrochemical (Yantai) Co., Ltd., Toagosei Co., Ltd, and China Petroleum & Chemical Corporation, among others. |

Single User License

One User

USD 4,399

USD 3,959

tax inclusive*

Datasheet

One User

USD 2,999

USD 2,699

tax inclusive*

Five User License

Five User

USD 5,599

USD 4,759

tax inclusive*

Corporate License

Unlimited Users

USD 6,659

USD 5,660

tax inclusive*

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Small Business Bundle

Growth Bundle

Enterprise Bundle

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share