Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Xenon Difluoride Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a xenon difluoride plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for xenon difluoride is increasing due to growth of semiconductor industries and expanding applications in pharmaceutical sector. XeF2 is extensively used in the semiconductor industry for etching silicon microprocessors. Its ability to selectively remove silicon oxide layers allows for high precision and miniaturisation in electronic devices. For example, the Samco VPE-4F etch system employs XeF2 to achieve isotropic etching of silicon sacrificial layers, essential for fabricating self-standing MEMS devices.

In microelectromechanical systems (MEMS), XeF2 is used to release structures by etching away sacrificial layers without damaging the remaining components. The Xetch-X3 system at University of California, Santa Barbara (UCSB) exemplifies this application, which allows for the isotropic dry etching of materials like silicon and germanium at room temperature. In the pharmaceutical sector, xenon difluoride is instrumental in making 5-fluorouracil, a key medication used in cancer treatment. The rising incidence of cancer have heightened demand for this compound.

Other elements to consider while establishing a xenon difluoride plant include raw material sourcing, workforce planning, and packaging. The production of xenon difluoride (XeF2) relies on several key raw materials, primarily xenon gas (Xe) and fluorine gas (F2). Xenon, a noble gas, is essential for the synthesis of XeF2 and is typically sourced from air separation processes. Fluorine, another critical reactant, is highly reactive and is used in a stoichiometric ratio with xenon to produce xenon difluoride. It is often generated through the electrolysis of potassium fluoride or obtained from fluorine suppliers. Manufacturers must procure high-quality raw materials for efficient production.

Moreover, to help stakeholders determine the economics of a xenon difluoride plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

However, challenges such as high production costs and market volatility may threaten the supply stability of xenon difluoride (XeF2). The intricate and expensive procedures required for its synthesis can restrict its use, particularly among smaller producers who may struggle to absorb these costs. Additionally, fluctuations in the prices of raw materials, such as xenon and fluorine, can create instability in the market, affecting manufacturers' profitability.

To combat these challenges, manufacturers of xenon difluoride can invest in technological advancements. By improving production efficiency and reducing waste, manufacturers can lower costs and enhance their ability to respond to market fluctuations. Furthermore, establishing strategic partnerships with suppliers can help secure a more stable supply of raw materials, mitigating risks associated with price volatility and availability. Implementing these strategies can significantly reduce supply chain risks and ensure a more consistent output of xenon difluoride.

Xenon difluoride (XeF2) is a chemical compound known for its powerful fluorinating properties and stability among xenon compounds. Discovered in 1962 by German chemist Rudolf Hoppe, it was produced by mixing xenon and fluorine in an electrical discharge process. This compound challenged the belief that noble gases were entirely inert by demonstrating that xenon could form stable compounds under specific conditions. Today, it is recognised for its applications in organic synthesis and material science.

Xenon difluoride is a dense, colourless crystalline solid with a molar mass of 169.29 g/mol. It has a melting point of 128.6 °C (263.5 °F) and a boiling point of 155 °C (311 °F). The compound is linear, with Xe-F bond lengths of 197.73 pm (picometers) in the vapor state and 200 pm in the solid phase. It has a density of approximately 3.1 g/cm3 at 25 °C. Xenon difluoride is moisture-sensitive, decomposing upon contact with water, and has a low vapor pressure of about 0.1 mmHg at room temperature. Chemically, it acts as a strong oxidising agent, with an oxidation state of +2 for xenon, and is soluble in solvents like anhydrous hydrogen fluoride (HF), making it useful in microelectromechanical systems (MEMS) etching. The compound can also react with various organic compounds, facilitating the formation of many fluorinated products.

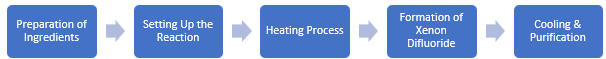

The production process of xenon difluoride (XeF2) involves several key steps, beginning with the preparation of xenon (Xe) and fluorine (F2) gases in a 2:1 molar ratio. The gases are then placed in a sealed nickel vessel, where the mixture is heated to approximately 400 °C (752 °F) to initiate the reaction. During this process, xenon and fluorine react to form xenon difluoride, represented by the equation: Xe + F2 → XeF2. After the reaction, the mixture is allowed to cool, and the xenon difluoride is purified through fractional distillation or selective condensation. The purified product is then stored in airtight containers, protected from moisture, and packaged for distribution and various applications.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The production of xenon difluoride involves the following steps:

1. Direct Fluorination of Xenon:

Xenon difluoride is produced by reacting xenon gas (Xe) with fluorine gas (F2) under controlled conditions of low pressure and temperature. The reaction is typically carried out in a sealed nickel or monel vessel to avoid contamination. The balanced chemical equation is as follows:

Xe (g) + F2 (g) → XeF2 (s)

(Xenon + Fluorine → Xenon Difluoride)

2. Reaction Conditions:

The reaction is typically performed at a temperature of around 400 K (127°C) and a pressure of 6 atmospheres. The reaction vessel is irradiated with UV light to promote the formation of xenon difluoride. Xenon and fluorine gases are mixed in a 1:1 molar ratio, and the reaction proceeds to completion under these conditions, resulting in solid XeF2.

3. Purification:

Once the reaction is complete, the xenon difluoride (XeF2) is purified by sublimation. This removes any residual xenon or fluorine gases and ensures a high-purity product. The sublimed XeF2 is then collected in a cooled zone of the reaction vessel.

4. Packaging and Distribution:

The purified xenon difluoride is carefully packaged in airtight containers to prevent moisture or light exposure, which could degrade the product. XeF2 is then distributed for use in various chemical applications, particularly in the semiconductor industry.

The xenon difluoride market is driven by its applications as a powerful fluorinating and oxidising agent in organic synthesis and materials science. Xenon difluoride is widely used in the fluorination of organic compounds, selectively targeting heteroatoms without affecting surrounding groups, making it valuable in the production of pharmaceuticals and speciality chemicals. Additionally, it serves as an isotropic etchant in semiconductor manufacturing, particularly in microelectromechanical systems (MEMS) fabrication. The market is further supported by the increasing demand for advanced materials and chemical processes that require precise fluorination.

A detailed overview of production cost analysis that evaluates the manufacturing process of xenon difluoride is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, the Indian Space Research Organisation (ISRO) is set to launch its first fully electric-propelled satellites, named the Technology Demonstrator Satellite (TDS-01), in December 2024. This may reduce demand for xenon and its derivatives, propelling manufacturers to explore alternative propellants and innovate their offerings to adapt to changing market dynamics.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a xenon difluoride production plant:

Market Dynamics and Trends: Growth factors such as increasing number of electric propulsion spacecraft and satellites using xenon ion propulsion systems significantly affect market conditions in the xenon difluoride sector. NASA's Dawn spacecraft used xenon ion thrusters and achieved significant velocity changes, showcasing XeF2 effectiveness in deep space missions. Additionally, the Artemis telecommunications satellite from the European Space Agency employs ion propulsion systems that use xenon to help it reach its intended orbit after a launch anomaly. Moreover, Orbion's Aurora thrusters, designed for small satellites, are also capable of maintaining orbits using similar ion propulsion technology. These examples illustrate how the increasing reliance on xenon ion thrusters for maneuvering and propulsion in various satellites creates a favorable market environment for xenon difluoride. Understanding these factors helps businesses align their production plans with demands and trends in the xenon difluoride market.

Profiling of Key Industry Players: Leading manufacturers like Airgas, Inc., Air Liquide, Linde plc, and Merck KGaA are included in the xenon difluoride market report. Recently, these companies have been focusing on expanding their supply chains to meet the growing demand for xenon difluoride, particularly in semiconductor applications and pharmaceuticals. For instance, Merck KGaA has emphasised its commitment to providing a stable and low-cost supply of XeF2, which is critical for its use in MEMS technology. This proactive approach helps mitigate supply chain risks and ensures that they can meet the needs of industries increasingly reliant on eco-friendly etching agents and advanced propulsion systems.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in xenon difluoride prices are influenced by several key factors, particularly the costs of essential raw materials such as xenon gas and fluorine gas. Xenon is a trace gas in the Earth's atmosphere, making its extraction expensive and subject to supply constraints, which can lead to price increases when demand surges. Similarly, fluorine, while more abundant, is highly reactive and requires careful handling, adding to its cost. As manufacturers strive to maintain profitability amid these challenges, they may need to explore alternative sourcing strategies or invest in more efficient production technologies to mitigate the impact of raw material cost fluctuations on their operations.

Establishing a xenon difluoride manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of a xenon difluoride manufacturing facility must comply with various regulatory frameworks. Key regulations include the Occupational Safety and Health Administration (OSHA) standards, which set exposure limits for hazardous substances like xenon difluoride, establishing a permissible exposure limit (PEL) of 2.5 mg/m3 for an 8-hour workday. Additionally, compliance with the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) is essential, as xenon difluoride is classified as a toxic and oxidising substance, necessitating proper labelling and safety measures during handling and storage.

Furthermore, facility must implement measures to prevent accidental releases of xenon difluoride or its byproducts, which can be harmful to both human health and the environment. They must also follow guidelines set by agencies such as the Environmental Protection Agency (EPA) regarding chemical safety assessments and risk management plans. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the xenon difluoride industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share