Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Triphenyl Phosphate Manufacturing Plant Project Report 2025 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a triphenyl phosphate plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The automotive sector is a significant driver increasing triphenyl phosphate (TPP) demand. With the rise of electric vehicles (EVs), which saw their market share jump from 3% in 2019 to 22% in 2022, the need for effective fire retardants has become critical due to the higher fire risk associated with EV batteries. TPP is used in lubricants and hydraulic fluids essential for vehicle performance and safety. The global vehicle production is projected to reach 35 million units in China by 2025, further boosting the demand for TPP as it is integrated into engine oils and other automotive fluids.

Other elements to consider while establishing a triphenyl phosphate plant include raw material sourcing, workforce planning, and packaging. The production of triphenyl phosphate (TPhP) primarily relies on two key raw materials: phenol and phosphorus oxychloride. Phenol, an aromatic compound, serves as one of the main reactants in the synthesis of TPhP, undergoing a nucleophilic substitution reaction with phosphorus oxychloride. Moreover, to help stakeholders determine the economics of a triphenyl phosphate plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

However, challenges such as fluctuating raw material prices and strict government regulations may threaten supply stability in the triphenyl phosphate market. To combat this, manufacturers of triphenyl phosphate can diversify their supply sources and invest in alternative raw materials to mitigate reliance on volatile commodities like phenol and phosphorus oxychloride. Additionally, implementing better inventory management practices and developing strategic partnerships with suppliers can further enhance resilience against supply chain risks. These strategies are essential for maintaining consistent production levels and ensuring long-term sustainability in the face of market uncertainties.

Triphenyl phosphate (TPP) is an organophosphate compound primarily used as a plasticiser and flame retardant. It was first produced in 1888 by the German chemist Wilhelm Manchot and gained prominence in various industries, particularly in electronics and automotive applications. Over the years, concerns regarding its environmental impact and potential health effects have led to increased scrutiny and regulation.

Triphenyl phosphate is a colourless crystalline solid with a faint phenol-like odour. It has a melting point of 48-50 °C and a boiling point of 245 °C. TPP has a density of approximately 1.2 g/cm3 at 20 °C and is practically insoluble in water, with a solubility of about 1.9 mg/L at 20 °C. It is highly soluble in organic solvents like carbon tetrachloride (solubility: 100 g/L) and acetone (solubility: 50 g/L). The compound is stable under neutral and acidic conditions but hydrolyses rapidly in alkaline environments, with a half-life of about 1 hour in a 0.1 M NaOH solution at 25 °C, making it a versatile yet potentially hazardous chemical.

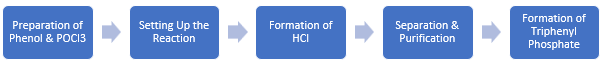

The production of triphenyl phosphate (TPP) begins with the preparation of raw materials, specifically phenol and phosphorus oxychloride. In a reactor, three moles of phenol are mixed with one mole of phosphorus oxychloride under elevated temperatures (80-120 °C) in the presence of a catalyst, resulting in the formation of TPP and hydrochloric acid as a by-product. The generated hydrochloric acid is scrubbed with water, while excess phenol is removed through fractional distillation. Finally, the purified triphenyl phosphate is collected in suitable containers for storage and distribution.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

Below is the detailed process of making triphenyl phosphate:

1. Preparation of phosphorus oxychloride (POCl3):

Phosphorus oxychloride is prepared from phosphorus trichloride (PCl3) by reaction with oxygen or sulfur trioxide.

PCl3 + O2 → POCl3

2. Esterification reaction:

Phosphorus oxychloride reacts with phenol in the presence of a base catalyst (e.g., pyridine or a tertiary amine) to form triphenyl phosphate (C18H15O4P). The reaction releases hydrogen chloride (HCl) as a by-product.

POCl3 + 3 C6H5OH → C18H15O4P + 3 HCl

(Phosphorus oxychloride + Phenol → Triphenyl phosphate + Hydrogen chloride)

3. Neutralisation:

The hydrogen chloride (HCl) produced during the esterification is neutralised using a base such as sodium hydroxide (NaOH), resulting in sodium chloride (NaCl) and water (H2O).

HCl + NaOH → NaCl + H2O

This process is used in the large-scale production of triphenyl phosphate, which is subsequently purified and used in various industrial applications, primarily as a flame retardant and plasticiser.

The triphenyl phosphate market is driven by its diverse applications, particularly in the automotive, electronics, and plastics industries. It is widely used as a plasticiser and flame retardant in polyvinyl chloride (PVC) products, enhancing their flexibility and fire resistance. The growing demand for lubricants in automotive applications, including engine oils and hydraulic fluids, further propels market growth. Additionally, the rise of electric vehicles, which require effective fire retardants due to their battery systems, is a significant market driver. The expansion of e-commerce has also increased the need for packaging materials that use triphenyl phosphate as a plasticiser, thereby boosting its market presence.

A detailed overview of production cost analysis that evaluates the manufacturing process of triphenyl phosphate is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, the rise in fire incidents has significantly influenced the incorporation of flame retardants, such as Triphenyl Phosphate (TPP), particularly in sectors like construction and electronics. In England, fire and rescue services reported attending 594,384 incidents in June 2024.

In the United States, California experienced 582,537 total emergency responses, including 7,958 wildfires, resulting in over 1 million acres burned during the 2024 fire season. These alarming statistics highlight the pressing need for effective fire prevention strategies. In response, the Bureau of Indian Standards (BIS) has developed specific regulations for flame retardants, such as IS 11871:2014, which outlines requirements for flame retardant like TPP to enhance protection across construction and electronics sectors.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a triphenyl phosphate production plant:

Market Dynamics and Trends: Growth factors such as expanding applications in plastic industry and increasing emphasis on fire safety across industries significantly affect market conditions in the triphenyl phosphate sector. As the e-commerce sector expands, so does the need for packaging materials that often contain plastics enhanced with TPP. This growth is evident as e-commerce sales are expected to exceed USD 6 trillion in 2024, marking an 8.4% increase from the previous year, necessitating increased production of plastic goods. Understanding these factors helps businesses align their production plans with demands and trends in the triphenyl phosphate market.

Profiling of Key Industry Players: Notable players include ICL Industrial Products and Lanxess, which are known for their extensive portfolios of speciality chemicals. Wego Chemical Group also serves as a global supplier and distributor of TPP. In India, Tina Organics Pvt. Ltd. and A.B. Enterprises are key manufacturers of TPP, supplying both domestic and international markets. National Analytical Corporation - Chemical Division and Salius Pharma Pvt. Ltd. also contribute to the Indian market. Chemvon Biotechnology (Shanghai) Co. Ltd. represents the Chinese manufacturing sector by providing TPP for industrial applications. Additionally, Ketan Chemical Corporation, CDH Fine Chemicals, and Muby Chemicals are known for their production and export of TPP from India. The collective efforts of these manufacturers are driving the growing demand for triphenyl phosphate.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in triphenyl phosphate (TPP) prices are influenced by several key factors, particularly the costs of essential raw materials such as phenol and phosphoric acid. Currently, the price of triphenyl phosphate varies depending on the supplier and quantity. For instance, TCI Chemicals lists TPP at approximately INR 2,700 for 25 grams and INR 3,800 for 500 grams. Other suppliers like Ketan Chemical Corporation offer it at around INR 100 per kilogram, while Salius Pharma Pvt. Ltd. lists it at INR 550 per kilogram. Additionally, market dynamics are affected by stringent regulations regarding fire safety, which increase demand for effective flame retardants like TPP, thereby influencing its price stability. The fluctuating costs of crude oil and environmental concerns associated with organophosphate compounds add another layer of complexity to the pricing landscape of triphenyl phosphate.

Establishing a triphenyl phosphate manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of a triphenyl phosphate (TPP) manufacturing facility must comply with various regulatory frameworks that govern chemical production and use. In the United States, TPP is classified as a high-priority substance under the Toxic Substances Control Act (TSCA), which mandates a comprehensive risk evaluation process to assess its safety and environmental impact. Manufacturers must adhere to reporting requirements, including the Chemical Data Reporting (CDR) rule, which necessitates that companies producing or importing over 25,000 pounds of TPP annually submit detailed reports on their activities.

In addition to federal regulations, TPP is knowns as a hazardous substance by OSHA and NIOSH, which means that facilities must implement stringent workplace controls to protect workers from exposure. Furthermore, in the European Union, TPP has been identified as a substance of very high concern (SVHC) under the REACH Regulation due to its endocrine-disrupting properties, necessitating careful risk assessments. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the triphenyl phosphate industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 2,699

USD 2,429

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 2,699

USD 2,429

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Our step-by-step guide will help you select, purchase, and access your reports swiftly, ensuring you get the information that drives your decisions, right when you need it.

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City,1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

United States

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

United States (Head Office)

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City, 1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

Share