Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Tobacco Moisture Meter Manufacturing Plant Project Report 2025 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a tobacco moisture meter plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for tobacco moisture meters is increasing due to rising need for quality control in tobacco processing and technological advancements. Maintaining optimal moisture levels is essential for ensuring the quality of tobacco products. The ideal moisture content for processed tobacco typically ranges between 12% and 16%. Exceeding this range can lead to mould growth, which negatively impacts flavour and aroma. Research has shown that proper moisture management during the drying stage significantly influences the quality of cut tobacco. For instance, advanced moisture sensors like MoistTech's Model 828 can measure moisture levels with an impressive accuracy of ±0.1%. This precision allows manufacturers to effectively monitor and control their processes, reducing waste and enhancing product consistency.

In addition, recent innovations in moisture measurement technology have greatly improved accuracy and efficiency in tobacco processing. Non-contact sensors that use near-infrared (NIR) technology enable real-time monitoring of moisture content without direct contact with the tobacco. These systems can achieve measurement accuracies of ±0.25% in high moisture applications, allowing for continuous data collection on other critical parameters such as nicotine and sugar content. Furthermore, the implementation of automated systems that integrate moisture measurement into production lines has demonstrated efficiency enhancements of up to 400%. This significant improvement makes it easier for manufacturers to meet regulatory compliance and consumer expectations in a competitive market.

Other elements to consider while establishing a tobacco moisture meter plant include raw material sourcing, workforce planning, and packaging. The production of tobacco moisture meters relies on key raw materials such as electronic components, special sensors, and durable housing materials. For instance, The PSC MCT460-T moisture analyzer from Process Sensors Corporation uses advanced technology for real-time moisture measurement in tobacco processing. It maintains a target range of 12.5% to 13.5% and can integrate with PLCs for rapid and continuous moisture measurements. The implementation of these technologies can lead to substantial operational efficiencies; for example, TEWS solutions have demonstrated a 75% reduction in sample preparation time, saving approximately EUR 13,750 annually in labour costs for companies processing up to 100 samples daily. This underscores the importance of integrating high-quality materials and cutting-edge technology to improve production efficiency and ensure consistent product quality in the tobacco industry.

Moreover, to help stakeholders determine the economics of a tobacco moisture meter plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

However, challenges such as disruptions in raw material availability, primarily electronic components or sensors, may threaten supply stability for the tobacco moisture meter market. These disruptions can significantly impact production timelines and overall manufacturing efficiency. To combat this, manufacturers can explore alternative sourcing strategies, such as establishing partnerships with local suppliers or investing in the development of proprietary sensors to reduce reliance on external vendors. By diversifying their supply chains, manufacturers of tobacco moisture meters can enhance their resilience against market fluctuations and ensure consistent product availability.

Tobacco moisture meters are essential tools used to measure the moisture content in tobacco leaves, crucial for ensuring quality during processing. These devices typically feature a measurement range of 8% to 40% moisture, with high accuracy and quick response times. They are widely used in tobacco farms, laboratories, and research institutes to maintain optimal moisture levels, which significantly influence the smoking quality and storage properties of tobacco.

Tobacco moisture meters have a measurement range of 8% to 40%, a resolution of 0.1%, and an accuracy of ±0.5%. They operate within a temperature range of 0 °C to 60 °C and can function in humidity levels from 5% to 90%. Chemically, they assess moisture levels, which affect the tobacco's chemical composition, influencing flavour, burn rate, and storage stability. These meters are vital for maintaining optimal tobacco quality throughout processing.

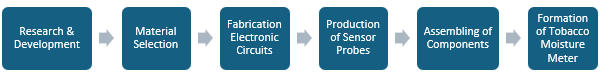

The production and manufacturing process of a tobacco moisture meter begins with research and development, where market needs are identified, and design specifications are established. Next, material selection occurs, focusing on suitable sensors (such as capacitive or infrared) and durable housing materials. Following this, manufacturing components involves fabricating electronic circuits, producing sensor probes, and assembling the housing. The assembly phase integrates sensors with electronic circuits and installs display and control interfaces. This is followed by calibration, where accuracy is tested, and settings are adjusted. Quality control ensures compliance with industry standards through performance testing. Finally, the product is packaged and distributed to retailers.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The tobacco moisture meter market is driven by the need for quality control and efficiency in tobacco processing. These meters are widely used in various applications, including leaf processing, blending, and reconstituted tobacco production, where precise moisture measurement is crucial for maintaining product quality and reducing waste. For example, MoistTech's Model 828 sensor is used for on-line moisture analysis during primary processing, enhancing production efficiency by up to 600%. Additionally, the increasing automation in tobacco manufacturing processes necessitates accurate moisture control to optimise drying and conditioning stages, further resulting in market growth.

Also, with an increase in tobacco consumption in emerging markets like Asia, the market for tobacco moisture meter is also expected to witness growth. The Global Adult Tobacco Survey (GATS) indicates that 44.3% of adults in India use tobacco in some form, with regional variations showing higher prevalence rates in the East (55.4%) and Northeast (51.8%). Smokeless tobacco is particularly prevalent, with usage rates increasing from 24.9% to 32.6% in the Northeast between GATS-1 and GATS-2. The National Family Health Survey (2019-2021) reported that 52.8% of males aged 50-64 years are tobacco users. As the market expands due to regional variations in tobacco consumption, the need for precise moisture measurement becomes increasingly vital for manufacturers.

A detailed overview of production cost analysis that evaluates the manufacturing process of tobacco moisture meter is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, Tobacco farmers in Zimbabwe are optimistic about reaching a target of 300 million kilograms for the 2024 season, up from 296 million kilograms produced in 2023. However, production is expected to decline to around 265 million kilograms due to El Nino-induced drought conditions, affecting planting and crop establishment. The government aims to increase value addition from the current 2% to over 30%, enhancing the economic contribution of the tobacco sector. As farmers aim to improve quality and yield, the demand for accurate moisture measurement tools will likely rise, leading to innovations within the tobacco moisture meter market.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a tobacco moisture meter production plant:

Market Dynamics and Trends: The tobacco industry is being influenced by rising consumer demand for tobacco products and stringent regulations. Globally, there are approximately 1.25 billion adult tobacco users. Regionally, South-East Asia has the highest percentage of tobacco users, accounting for 26.5% of the population. Countries like India contribute significantly to this figure, with an estimated 253 million tobacco users, making it the second-largest consumer globally. Europe follows closely with a prevalence of 25.3%. Notably, tobacco use among women in this region is more than double the global average. Indonesia and Egypt are also among the countries where tobacco use is on the rise. Many countries are implementing stricter regulations on advertising and public smoking to combat health risks associated with tobacco use. The World Health Organization (WHO) has stated the need for continued efforts in tobacco control policies to mitigate industry interference and promote public health initiatives. Understanding these dynamics is crucial for businesses, particularly those involved in the tobacco moisture meter sector, as they align their production strategies with market demands.

Profiling of Key Industry Players: Leading manufacturers in the tobacco moisture meter sector include MoistTech, Bionics Scientific, Weiber, Kyoritsu Kew India Instruments Pvt. Ltd., Innovative Instruments, Jupiter Integrated Sensor Systems Pvt. Ltd., and Dickey-John. These companies are known for their advanced technologies and reliable products that ensure accurate moisture measurement in tobacco processing. MoistTech is known for its Model 828, which uses near-infrared (NIR) technology to provide precise moisture measurements, enhancing production efficiency by up to 400% and requiring no recalibrations over time. Bionics Scientific offers portable and rugged moisture meters that meet international standards, featuring a moisture range of 2% to 40% and a temperature range of 0ºC to 60ºC. Weiber produces a versatile 2-in-1 meter that measures both moisture and temperature in tobacco leaves. Dickey-John has developed specific meters for cigarette moisture testing, ensuring quality control in tobacco products.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in tobacco moisture meter prices are influenced by several key factors, particularly the costs of essential raw materials such as sensors, circuit boards, and housing materials. Recent price trends indicate that moisture meters range from INR 13,500 to INR 26,000 in India, depending on features such as accuracy, data logging capabilities, and connectivity options. For instance, high-end models with advanced features can reach prices as high as INR 30,000.

The global semiconductor shortage has also impacted the availability and cost of electronic components, leading to price increases of approximately 10-15% over the past year. As demand for precision agriculture tools rises due to the anticipated increase in tobacco production, manufacturers may adjust prices further to reflect both rising production costs and the need for innovative features in moisture measurement technology.

Establishing a tobacco moisture meter manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

Establishing a tobacco moisture meter manufacturing facility requires compliance with various regulatory frameworks designed to ensure product quality and safety. In the United States, the Food and Drug Administration (FDA) regulates tobacco products under the Family Smoking Prevention and Tobacco Control Act, which includes stipulations on moisture content, such as a maximum limit of 20% moisture for cigarettes. Additionally, manufacturers must adhere to International Organization for Standardization (ISO) guidelines, particularly ISO 9001, which helps ensure consistent product quality.

ASTM International also provides specific standards relevant to moisture measurement in tobacco; for instance, ASTM E1959 details standard test methods for measuring moisture content using various techniques. Compliance with National Institute of Standards and Technology (NIST) specifications is essential to guarantee accurate measurements, which are critical for maintaining product quality. Furthermore, in India, the Ministry of Consumer Affairs has draft rules outlining technical requirements for moisture meters. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the tobacco moisture meter industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 2,699

USD 2,429

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 2,699

USD 2,429

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Our step-by-step guide will help you select, purchase, and access your reports swiftly, ensuring you get the information that drives your decisions, right when you need it.

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City,1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

United States

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

United States (Head Office)

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City, 1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

Share