Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Surgical Eyelash Glue Manufacturing Plant Project Report 2025 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a surgical eyelash glue plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The overall growth in cosmetic procedures is significantly contributing to the demand for surgical eyelash glue. In 2022, there were 31,057 cosmetic procedures performed in the UK, marking a 102% increase from the previous year. This upward trend has continued into 2024, with approximately 26,000 procedures recorded in just the first quarter of 2024. Women accounted for about 93% of all cosmetic procedures, with popular treatments including breast augmentation, breast reduction, tummy tucks, liposuction, and blepharoplasty (eyelid surgery), which collectively saw significant increases in demand.

Interestingly, men represented around 7% of these procedures, with a notable rise in rhinoplasty and eyelid surgeries. The British Association of Aesthetic Plastic Surgeons (BAAPS) anticipates that the demand for cosmetic surgeries will continue to grow throughout 2024 as societal norms shift towards greater acceptance of aesthetic enhancements. This growing acceptance and interest in various cosmetic treatments are driving the demand for surgical eyelash glue as well.

Other elements to consider while establishing a surgical eyelash glue plant include raw material sourcing, workforce planning, and packaging. The production of surgical eyelash glue relies on several key raw materials essential for creating a safe and effective adhesive. The primary ingredient is cyanoacrylate, particularly ethyl cyanoacrylate, known for its fast-curing properties and strong bonding capabilities. Thickening agents, such as polymethyl methacrylate (PMMA) and silica, are added to adjust the glue's viscosity for easy application. Stabilisers like hydroquinone prevent premature polymerisation during storage, although alternatives are being explored due to regulatory changes in the EU. Colourants, such as carbon black, improve the adhesive's aesthetic appeal, allowing it to blend seamlessly with both natural lashes and extensions. These materials contribute to high-quality surgical eyelash glue that meets safety standards while providing reliable adhesion for eyelash enhancements.

Moreover, to help stakeholders determine the economics of a surgical eyelash glue plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

However, challenges such as disruptions in raw material availability, primarily cyanoacrylate, may threaten supply stability. To combat these challenges, manufacturers of surgical eyelash glue can explore alternative sources for key ingredients, such as developing synthetic substitutes or sourcing from different suppliers to mitigate risks associated with single-source dependencies. Additionally, investing in more efficient production technologies can help reduce utility costs, improve overall operational efficiency, and ensure a stable supply of surgical eyelash glue to meet the growing demand in the market.

Surgical eyelash glue is a specialised adhesive used for applying false eyelashes or eyelash extensions. It is formulated to provide a strong bond while being safe for use near the eyes, minimising irritation, and allergic reactions. Typically, these glues contain cyanoacrylate, which polymerises quickly upon contact with moisture, ensuring a secure hold. However, proper application techniques are crucial to avoid damaging natural lashes and to ensure longevity.

Recently, researchers from the University of Essex have investigated the potential of mistletoe as a surgical glue, specifically its adhesive substance called viscin. This project aims to develop an eco-friendly sealant, leveraging mistletoe's unique properties, such as its ability to adhere to both biological tissues and synthetic materials, making it suitable for medical use. This innovative use could pave the way for safer and more effective surgical practices in the future, leading to market expansion.

Surgical eyelash glue is primarily composed of cyanoacrylate, a fast-curing adhesive and its viscosity typically ranges from 200 to 500 centipoise, allowing for easy application without excessive dripping. Their curing time is remarkably rapid, often within 1 to 5 seconds, depending on humidity levels, which can range from 40% to 70% for optimal performance. Most formulations are either black or clear, enhancing their aesthetic appeal. Chemically, they contain about 90-95% cyanoacrylate and 5-10% additives for stabilisation and thickening. Modern surgical eyelash glues are designed to be safe, often free from harmful substances like formaldehyde, significantly reducing the risk of allergic reactions and irritation.

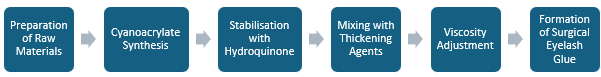

The production process of surgical eyelash glue begins with the acquisition of raw materials, including cyanoacrylate monomers, thickening agents, stabilisers like hydroquinone, and colourants. The cyanoacrylate is synthesised from cyano acrylic acid, after which hydroquinone is added to stabilise the adhesive and prevent premature polymerisation. Next, the stabilised cyanoacrylate is mixed with thickening agents, such as PMMA or silica, to achieve the desired viscosity, typically ranging from 1,000 to 600,000 centipoise. Once the viscosity is adjusted, the final adhesive is packaged into suitable containers for distribution.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The process of making surgical eyelash glue involves the synthesis and blending of various ingredients, ensuring the product is non-toxic, hypoallergenic, and has a suitable viscosity for easy application.

1. Preparation of Raw Materials

The primary ingredients used in surgical eyelash glue include cyanoacrylates, which are fast-curing adhesives, and various stabilisers, plasticisers, and additives that ensure the adhesive remains flexible and safe for use. Commonly used cyanoacrylates in medical adhesives are ethyl cyanoacrylate and butyl cyanoacrylate.

2. Synthesis of Cyanoacrylate

The cyanoacrylate used in eyelash glue is synthesised through a process that involves the polymerisation of cyanoacrylate monomers. The chemical reaction is as follows:

Chemical Reactions

Polymerisation of Cyanoacrylate:

CH2 = C(CN)COOR (Cyanoacrylate Monomer) → [CH2=C(CN)COOR]n (Polymer)

In this reaction, R represents an alkyl group, such as ethyl or butyl, depending on the specific type of cyanoacrylate being made.

3. Blending with Additives

Once the cyanoacrylate polymer is produced, it is blended with various additives to improve the adhesive's properties. These additives may include:

4. Homogenisation

The blended mixture is then homogenised to ensure that all ingredients are uniformly distributed throughout the adhesive. This step is crucial for achieving a consistent product with the desired properties.

5. Packaging

After homogenisation, the surgical eyelash glue is packaged in airtight containers to prevent exposure to moisture, which could trigger premature curing. The packaging process is done under controlled conditions to ensure the product's stability and shelf life.

The surgical eyelash glue market is driven by the increasing popularity of eyelash extension procedures, the rise in the geriatric population, and the growing demand for minimally invasive cosmetic treatments. Surgical eyelash glue is primarily used to attach artificial or synthetic eyelashes to natural lashes, providing a longer, fuller appearance. The market is also driven by the need for safe, fast, and easy application techniques that can overcome the disadvantages of conventional adhesives. For instance, the incorporation of bonding accelerators into cyanoacrylate-based adhesives can drastically reduce the time required to attach eyelash extensions, from less than 30 seconds to less than 5 seconds, making the procedure more efficient and cost-effective for both customers and beauty technicians.

A detailed overview of production cost analysis that evaluates the manufacturing process of surgical eyelash glue is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, the introduction of Super Bonder Technology has changed production of lash adhesives as it allows them to dry in just 30 seconds while increasing retention by up to 30%. This innovation not only reduces application time but also reduces irritation for clients sensitive to traditional adhesives. Another notable advancement is the development of UV curing adhesives, which only harden when exposed to UV light. Manufacturers are also focusing on hypoallergenic formulations that eliminate harmful substances like formaldehyde, catering to consumers with sensitive skin. As a result, the surgical eyelash glue market is becoming increasingly competitive.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a surgical eyelash glue production plant:

Market Dynamics and Trends: Growth factors such as the influence of social media significantly affect market conditions in the surgical eyelash glue sector. Platforms like Instagram have become pivotal in shaping beauty trends as makeup tutorials and influencer endorsements are showcasing various eyelash styles and application techniques. The hashtag #LashExtensions has also garnered millions of views, leading to increased consumer awareness and interest in eyelash enhancements.

As per industry reports, over 70% of millennials and Gen Z consumers are influenced by social media when making beauty purchases. Brands are leveraging this trend by launching targeted marketing campaigns on social media. In April 2024, BL Lashes introduced their Optimo long-lasting lash glue. The launch was promoted through influencer partnerships, leveraging social media to enhance brand visibility and credibility. Understanding these trends helps businesses align their production plans with demands and trends in the surgical eyelash glue market.

Profiling of Key Industry Players: Leading manufacturers like Duo, BL Lashes, and H.B. Fuller are included in the surgical eyelash glue report. Recently, Duo launched a new line of latex-free adhesives designed for sensitive skin. H.B. Fuller has introduced a range of water-based adhesives that cater to various performance preferences, ensuring durability while being gentle on the eyes. Other notable players include TLS Supplies, which is known for their its quick=drying surgical hold glue, and Sumformi Korean, which offers a variety of eyelash glues with extended wear capabilities. These companies are continuously innovating to meet the growing demand for effective and safe eyelash enhancement products in the beauty industry.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Establishing a surgical eyelash glue manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of a surgical eyelash glue manufacturing facility must comply with various regulatory frameworks that govern production standards. in the European Union, eyelash adhesives are classified under Regulation (EC) No 1223/2009, which mandates that cosmetic products meet stringent safety and labelling requirements. This includes ensuring that all ingredients used are safe for human health and properly documented. Manufacturers must adhere to the Pharmaceutical Affairs Law in Japan, which requires that any adhesive used for eyelash extensions meets specific cosmetic standards to avoid health risks. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the surgical eyelash glue industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 2,699

USD 2,429

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 2,699

USD 2,429

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Our step-by-step guide will help you select, purchase, and access your reports swiftly, ensuring you get the information that drives your decisions, right when you need it.

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City,1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

United States

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

United States (Head Office)

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City, 1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

Share