Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Silver Oxide Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a silver oxide plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for silver oxide is increasing due to the growing use of silver oxide batteries in various electronic devices. These batteries are favored for their high energy weight ratio and durability, making them ideal for applications in calculators, watches, and hearing aids. Both analog and digital watches use silver oxide batteries for their compact size and long-lasting performance. Devices like hearing aids and portable medical instruments rely on silver oxide batteries due to their reliability and longevity. Other applications include toys, cameras, and LCD displays, which benefit from the batteries' stable discharge characteristics. As the production of these devices increase, the market is also set to achieve robust growth.

Other elements to consider while establishing a silver oxide plant include raw material sourcing, workforce planning, and packaging. Silver Nitrate (AgNO3) is one of the primary raw materials for producing silver oxide. It is often reacted with alkali hydroxides to form silver oxide through precipitation. Commonly used alkali hydroxides include sodium hydroxide (NaOH), potassium hydroxide (KOH), and lithium hydroxide (LiOH). Silver oxide can also be produced directly from elemental silver in the presence of oxygen at elevated temperatures. In some advanced methods, solvents such as water, alcohols, or glycols may be used alongside various silver complex compounds. These raw materials ensure the production of high purity silver oxide.

Moreover, to help stakeholders determine the economics of a silver oxide plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Silver oxide (Ag2O) is an inorganic compound composed of two silver atoms and one oxygen atom. It is a dark brown or black powder used in various applications, including batteries, photography, and as an oxidising agent in organic chemistry. Silver oxide was first discovered in the early 19th century and has been used in the first alkaline batteries developed in the 1930s, as well as in spacecraft batteries, such as those in the Apollo missions. Silver oxide can be produced by reacting silver nitrate with sodium hydroxide: 2AgNO3 (aq) + 2NaOH (aq) → Ag2O (s) + 2NaNO3 (aq) + H2O (l). This reaction produces silver oxide as a precipitate.

Silver oxide is a dark brown or black powder with a molar mass of 231.7 g/mol and a density of 7.14 g/cm cube. It has a cubic crystal structure and a melting point of 300°C. Silver oxide is slightly soluble in water, with solubility increasing with temperature. It is soluble in acids, alkali solutions, and ammonia, forming Tollen's reagent. Silver oxide decomposes at temperatures above 280°C, releasing oxygen gas.

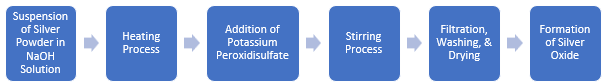

The production of silver oxide begins with suspending silver powder in a sodium hydroxide solution, which is then heated to 85°C. Potassium peroxidisulfate is added in parts over the course of an hour, with continued stirring for at least three hours after the final oxidant addition. The resulting mixture is filtered to collect the silver oxide product, which is then washed to remove any alkali substances and dried at approximately 80°C to reduce it to a powder.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The production of silver oxide involves the following steps:

Step 1: Preparation of Silver Nitrate Solution

Silver oxide is produced by first preparing a solution of silver nitrate. Silver metal is dissolved in nitric acid (HNO3) to form silver nitrate.

The reaction can be represented as: 3 Ag + 4 HNO3 → 3 AgNO3 + NO + 2 H2O

The resulting silver nitrate solution is then ready for use in the next step.

Step 2: Precipitation of Silver Oxide

The silver nitrate solution is reacted with sodium hydroxide (NaOH) to precipitate silver oxide (Ag2O).

The reaction proceeds as follows: 2 AgNO3 + 2 NaOH → Ag2O + 2 NaNO3 + H2O

Silver oxide precipitates out of the solution as a dark brown or black solid. Sodium nitrate (NaNO3) remains dissolved in the solution.

Step 3: Filtration and Washing

Once the silver oxide is precipitated, the mixture is filtered to separate the solid silver oxide from the liquid sodium nitrate solution. The silver oxide is then washed with distilled water to remove any residual sodium nitrate and other impurities.

Step 4: Drying and Packaging

After filtration and washing, the silver oxide is dried in controlled conditions, ensuring that no moisture remains. The dried silver oxide is then packaged in airtight containers.

The silver oxide market is driven by growing demand from the electronics and healthcare industries. In electronics, silver oxide is extensively used in batteries for devices like hearing aids, watches, calculators, and portable electronics due to its high energy density and durability. The miniaturisation of electronic gadgets is also fuelling demand for small, high-energy silver oxide batteries. In healthcare, silver oxide's antibacterial properties make it an important component in antimicrobial creams and wound dressings, as well as in medical devices like pacemakers and implants. The increasing popularity of electronic wearables and ongoing innovations in battery and medical device technology are further driving market growth.

A detailed overview of production cost analysis that evaluates the manufacturing process of silver oxide is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, in November 2024, Silver Elephant Mining Corp. reported the mining of 24,153 wet tonnes of silver oxide materials with an average grade of 197 g/t silver from its Paca project. Since operations began in October 2023, the company has mined a total of 261,530 wet tonnes grading 183 g/t silver, equating to approximately 1,440,219 ounces of silver. This increase in supply could help stabilise prices amid rising demand, particularly from the electronics and healthcare sectors, where silver oxide is essential for batteries and antimicrobial applications.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a silver oxide production plant:

Market Dynamics and Trends: Factors such as expanding photovoltaic (PV) market is driving demand as silver oxide is essential for producing solar panels. In 2020, the solar industry consumed approximately 101 million ounces (3,142 tonnes) of silver, with projections indicating that silver's share of total consumption in the PV sector will rise to 14% by 2024. Current technologies such as Passivated Emitter and Rear Contact (PERC) cells require about 10 mg of silver per watt, while newer Tunnel Oxide Passivated Contact (TOPCon) cells demand around 13 mg per watt, and Heterojunction (SHJ) cells require up to 22 mg per watt, showcasing demand for the market. Furthermore, it is projected that the solar sector could exhaust between 85% and 98% of global silver reserves by 2050, creating significant implications for silver oxide manufacturers. As the demand for silver in photovoltaic (PV) technology continues to rise, reaching 193.5 million ounces in 2023, up from 118.1 million ounces in 2022, this increasing consumption could drive prices for silver oxide and related materials. Understanding these factors helps businesses align their production plans with demands and trends in the silver oxide market.

Profiling of Key Industry Players: The silver oxide market is dominated by several leading companies that play a crucial role in the production and innovation of silver oxide batteries. Key players include Panasonic Corporation, Energizer Holdings, Inc., Duracell Inc., Sony Corporation, and Maxell Holdings, Ltd. Other notable competitors such as Renata SA, Seiko Instruments Inc., VARTA AG, Murata Manufacturing Co., Ltd., GP Batteries International Limited, and Camelion Battery Co., Ltd. further diversify the landscape of the silver oxide battery market. Companies are actively investing in research and development to reduce production costs while improving product quality.

Additionally, leading players are seeking alternative materials or innovative production techniques that reduce silver consumption in solar cells to below 2 mg/W. This is because solar panels require about 20 grams of silver each and the solar energy production, which is expected to expand from 135 GW in 2020 to 3 TW by 2030 is placing immense pressure on silver supplies.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in silver oxide prices are influenced by several key factors, particularly the costs of essential raw materials such as silver itself. The price of silver is subject to significant volatility due to supply and demand imbalances; when demand exceeds supply, prices tend to rise, while an oversupply can lead to price declines. Additionally, the costs associated with mining silver, including labor, fuel, and equipment expenses, directly impact the overall price of silver oxide products. If production costs increase but demand remains stable or grows, this typically results in higher prices for silver oxide batteries. Furthermore, inflationary pressures can lead to increased interest in silver as a hedge against currency devaluation, further influencing the market price.

Establishing a silver oxide manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of a silver oxide manufacturing facility must comply with EU Battery Directive (REGULATION (EU) 2023/1542), which mandates that all batteries, including silver oxide types, be virtually mercury-free. This directive aims to lower the environmental impact of battery production and disposal by prohibiting the use of hazardous materials like mercury and lead in battery manufacturing. However, silver oxide batteries are classified as "dry cell" batteries and are not subject to hazardous materials regulations under transportation guidelines set by U.S. Department of Transportation and the International Air Transport Association. But manufacturers must still ensure compliance with safety data sheets. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the silver oxide industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share