Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Lithium Carbonate Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a lithium carbonate plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for lithium carbonate is experiencing significant growth, primarily driven by the global transition to clean energy technologies and the rise of electric vehicles (EVs). As countries strive to reduce carbon emissions, there is an increasing reliance on renewable energy systems like solar and wind power. By 2025, renewable energy sources are projected to account for 35% of global electricity generation, with solar and wind power expected to surpass hydropower generation in 2024. In 2024 alone, solar power is anticipated to make up more than half of new capacity additions in the U.S., reflecting a broader trend where global renewable electricity generation is forecasted to climb to over 17,000 terawatt-hours (TWh) by 2030, marking a nearly 90% increase from 2023. This shift towards sustainable energy not only highlights the critical role of lithium in modern energy systems but also indicates that demand for lithium carbonate will continue to rise as renewable energy adoption expands.

The automotive industry’s rapid shift towards electric vehicles is another major factor contributing to the increasing demand for lithium carbonate. The International Energy Agency (IEA) projects that by 2025, there will be around 20 million new EVs on the road, significantly increasing the demand for lithium used in batteries. EVs require substantially more copper and lithium than traditional combustion engine vehicles, and estimates suggest that the demand for lithium could exceed 1 million tons annually by 2030 due to rising EV production. This surge in electric vehicle manufacturing further fuels the need for lithium carbonate in battery production.

Other elements to consider while establishing a lithium carbonate plant include raw material sourcing, workforce planning, and packaging. The production of lithium carbonate, particularly for lithium carbonate applications, relies on spodumene, brine, and sodium carbonate. Spodumene, a lithium-rich mineral, is a primary source of lithium, containing about 3.73% lithium by weight. It is extracted through crushing and roasting, followed by leaching with sulfuric acid to produce lithium sulfate, which is then converted into lithium carbonate. Lithium can also be sourced from brines, found in salt flats and underground reservoirs, which account for about 60% of global lithium reserves. Additionally, sodium carbonate (soda ash) is used in the production process, as it is used to convert lithium sulfate into lithium carbonate. These materials are necessary for achieving high-purity lithium carbonate (99.5% or greater).

Moreover, to help stakeholders determine the economics of a lithium carbonate plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Lithium carbonate (Li2CO3) is an inorganic compound widely recognised for its use in treating bipolar disorder and other mood disorders. Its medical application began in the 19th century, initially for gout and other ailments. The modern therapeutic use of lithium was pioneered by Australian psychiatrist John Cade in 1949, who discovered its calming effects on manic patients after observing its impact on guinea pigs. By the 1970s, lithium carbonate was officially approved for psychiatric use in the U.S. Today, it remains a critical component in mental health treatment and is listed among essential medicines by the World Health Organisation (WHO).

Lithium carbonate (Li2CO3) is a white crystalline powder with a molar mass of 73.89 g/mol and a density of 2.11 g/cm³. It has a melting point of 723 °C (1,333 °F) and decomposes at approximately 1,310 °C (2,390 °F). Its solubility in water is relatively low, at 1.54 g/100g at 0 °C and decreasing to 0.72 g/100g at 100 °C, while it is slightly soluble in alcohol and other organic solvents. The pH of its aqueous solution is around 10.5, indicating basicity. Lithium carbonate is stable under normal conditions and reacts with acids to form lithium salts and carbon dioxide. It is primarily used in pharmaceuticals for treating bipolar disorder and depression, as well as in ceramics where it acts as a flux in glass and porcelain production. Additionally, it serves as a precursor for lithium-ion battery production.

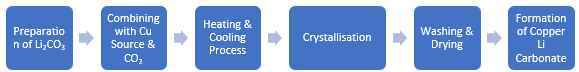

The production of lithium carbonate (Li2CO3) begins with the extraction of lithium from brine or spodumene ore. In the brine method, lithium-rich brine is pumped into evaporation ponds, where solar evaporation concentrates the lithium. Once concentrated, soda ash is added to precipitate lithium carbonate at elevated temperatures (60-90 °C). The precipitate is then filtered, washed, and dried to yield impure lithium carbonate. In the spodumene method, the ore is roasted with sulfuric acid to produce lithium sulfate, which is then reacted with carbon dioxide to form lithium carbonate. The final product undergoes purification through washing and drying to achieve battery-grade quality.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

1. Extraction of Lithium-Containing Brine

The process often begins with the extraction of lithium-rich brine from salt flats. These brines contain lithium chloride (LiCl) along with other salts and minerals.

2. Concentration of Brine

The brine is concentrated by evaporating water under sunlight. This step increases the concentration of lithium chloride in the solution.

3. Precipitation of Magnesium and Calcium

To remove impurities like magnesium (Mg) and calcium (Ca), lime (CaO) is added to the solution. This leads to the precipitation of magnesium hydroxide (Mg(OH)2) and calcium sulfate (CaSO4).

4. Conversion to Lithium Carbonate

Once the solution is purified, sodium carbonate (Na2CO3) is added to precipitate lithium carbonate (Li2CO3) from the lithium chloride solution.

Reaction: 2LiCl + Na2CO3 → Li2CO3 ↓ + 2NaCl

5. Filtration and Drying

The lithium carbonate precipitate is then filtered out of the solution, washed, and dried to produce pure lithium carbonate powder.

As a key material for lithium-ion batteries, lithium carbonate is essential for improving the performance of cathode materials such as lithium iron phosphate (LFP) and nickel-manganese-cobalt (NMC) compounds, which are widely used in electric vehicles (EVs) and renewable energy systems. In 2024, the global electric vehicle (EV) market is expected to grow significantly, with projected sales reaching around 17 million units, about 27% higher than 2023. China, being the largest EV market, expected to sell around 10 million units. In the United States, EV sales are predicted to account for one in nine cars, with Europe seeing electric vehicles comprising about 25% of total car sales. This data underscores the increasing demand for lithium carbonate as a key material in battery production, driven by the expanding EV market and renewable energy systems.

Moreover, by 2024, governments are focusing on reducing carbon emissions and enhancing energy storage capacity. In 2023, global lithium production surged by 23% to 180,000 tons, driven by demand for lithium-ion batteries. The U.S. Geological Survey also projects a 10-fold increase in lithium processing capacity over the next decade to meet the rising demand for energy storage, especially in EVs. In response to this, government policies like the U.S. Bipartisan Infrastructure Law and the Inflation Reduction Act are incentivising domestic lithium extraction and battery production, leading to growth of lithium carbonate market.

Lithium carbonate also acts as a cornerstone in the treatment of bipolar disorder. According to the WHO, lithium carbonate is included on the List of Essential Medicines. Studies show that lithium can reduce the risk of suicide by up to 60% compared to placebo, highlighting its significant protective effects for patients with bipolar disorder. A survey of psychiatrists revealed that over 70% prescribe lithium to more than half of their bipolar patients. Additionally, lithium is noted for its neuroprotective properties and its ability to prevent relapses. Lithium carbonate also plays a significant role in glass and ceramics manufacturing, and metallurgical industry, where it acts as a deoxidiser in copper and nickel smelting to improve metal purity.

A detailed overview of production cost analysis that evaluates the manufacturing process of lithium carbonate is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. According to recent data from November 2024, China's total production of lithium carbonate steadily increased by 8% month-over-month (MoM) and 49% year-over-year (YoY). For January 2025, expectations indicate that domestic production of lithium carbonate will further increase by 8%-10% MoM, reflecting strong supply and demand dynamics in the market.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a lithium carbonate production plant:

Geographical Analysis: Chile is the world's second-largest lithium producer, behind Australia. In 2022, SQM, a private company dealing with lithium in Chile, sold 157,000 metric tons of lithium carbonate, accounting for 75% of Chile's total production, while Albemarle contributed around 50,000 tons. Lithium exports generated over USD 7.763 billion in 2022, marking a 777% increase from 2021. However, in 2024, Chile faced regulatory hurdles that can delay mining operations and limit supply, potentially leading to a shortfall as global demand escalates. In response, Chilean President Gabriel Boric launched a National Lithium Strategy aimed at enhancing state control over lithium production while allowing private companies to participate in new developments. This initiative includes establishing a National Lithium Company and focusing on strategic projects in the Atacama salt flat. This strategy aims to position Chile as the world's leading lithium producer.

Profiling of Key Industry Players: Leading manufacturers like Albemarle Corporation, SQM S.A., and Ganfeng Lithium Group Co., Ltd are included in the lithium carbonate report. Recently, Arcadium Lithium, formed from the merger of Allkem and Livent, has become a significant player in the lithium market, enhancing its production capabilities and expanding its operations across multiple regions. This merger, valued at USD 10.6 billion, positioned Arcadium as a vertically integrated company involved in both lithium mining and processing, with assets in Argentina, Australia, and downstream facilities in the United States, China, Japan, and the United Kingdom.

In addition to these developments, the lithium market is witnessing increased production capacities among these leading firms. For instance, SQM has announced plans to expand its lithium production at the Salar del Carmen in Chile from 180,000 metric tons to 210,000 metric tons starting this year. Meanwhile, in June 2023, Jiangxi Ganfeng Lithium launched several large joint venture projects, including the Cauchari-Olaroz brine mine in Argentina, which plans to produce 40,000 tons per annum (tpa) of lithium carbonate. Ganfeng aims to achieve a total lithium carbonate equivalent production target of 300,000 tpa by 2025 and 600,000 tpa by 2030.

Additionally, players are engaging in mergers and acquisitions to increase their market share. Zijin Mining Group is in talks to acquire a stake in Zangge Mining Co. Ltd., which has a market value of USD 6.4 billion, as part of its strategy to expand its presence in the lithium market. Zangge produced approximately 9,278 tons of lithium carbonate in the first nine months of 2024. This acquisition aligns with Zijin's goal to ramp up lithium production to 300,000 tons by 2028 amid a projected demand boom for electric vehicle batteries.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in lithium carbonate prices are influenced by several key factors, including supply and demand dynamics, technological advancements, and geopolitical elements. In 2023, lithium prices experienced a dramatic decline, with prices for lithium hydroxide and lithium carbonate dropping by over 80% from their record highs in 2022. As of early January 2025, lithium carbonate prices were assessed at around USD 14.00-USD 14.50 per kg for battery-grade products in China, Japan, and South Korea, with the CIF North Asia price reaching approximately USD 14,600 per tonne in May 2023. The rapid expansion of lithium production has led to temporary oversupply situations that affect prices. Additionally, innovations in battery technology and extraction methods can enhance efficiency and influence market pricing. Regulatory changes in lithium-rich countries like Chile and Australia also impact global supply chains. These dynamics create a volatile market environment.

Establishing a lithium carbonate manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of a lithium carbonate manufacturing facility must comply with various regulatory frameworks that govern production standards, environmental impacts, and worker safety. Key regulations include the Clean Water Act, which mandates effluent limitations for lithium carbonate production to prevent water pollution, as outlined in 40 CFR 415. Additionally, facilities must adhere to Good Manufacturing Practices (GMP) as specified by the FDA, ensuring that production processes meet safety and quality standards for any pharmaceutical applications of lithium carbonate.

Moreover, the production process typically involves carbonation of lithium sulfate, which can generate hazardous by-products that must be managed according to local and national environmental laws. Furthermore, companies must implement specific engineering controls to mitigate risks associated with handling lithium carbonate. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the lithium carbonate industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share