Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Lasagna Rolls Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a lasagna rolls plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

One significant driver fuelling demand for lasagna rolls is the convenience they offer; lasagna rolls are individually portioned, making them ideal for busy lifestyles where quick and easy meal options are essential. For example, brands like Stouffer's and Amy's Kitchen have introduced frozen lasagna roll products that can be easily heated in the microwave, appealing to families and individuals looking for meals that require minimal preparation. Moreover, lasagna rolls can be made with various fillings and sauces, which further fuels demand. For instance, restaurants often feature spinach and ricotta lasagna rolls or mushroom and truffle oil rolls.

Another factor contributing to the rising popularity of lasagna rolls is the influence of Italian cuisine, which has gained global traction. As consumers increasingly explore Mediterranean flavours, lasagna rolls market is set to grow. Health-conscious trends also play a role; many home cooks are opting for lighter ingredients, such as whole wheat pasta or plant-based fillings, to create healthier versions of this classic dish. Also, brands like Banza offer chickpea pasta lasagna rolls that cater to gluten-free diets. Furthermore, social media has amplified their visibility through visually appealing recipes shared by food bloggers and influencers on platforms like Instagram and TikTok. These factors are growing the demand for lasagna rolls in today’s culinary landscape.

Other elements to consider while establishing a lasagna rolls plant include raw material sourcing, workforce planning, and packaging. The production of lasagna rolls relies on primarily lasagna sheets, cheese, and meat or vegetable fillings. Lasagna sheets, which are the foundation of the dish, are typically made from durum wheat semolina or all-purpose flour. These ingredients are sourced from grain producers and milling companies that specialise in pasta production. Brands like Barilla and De Cecco are well-known for their high-quality pasta products, including lasagna noodles. Additionally, various types of cheese such as ricotta, mozzarella, and Parmesan are essential for the filling and topping of lasagna rolls. These cheeses are sourced from dairy farms and cheese manufacturers. In terms of fillings, ground meats like beef or sausage are commonly used, along with vegetables such as spinach or zucchini for vegetarian options. These ingredients are sourced from local farms or meat processing plants. These raw materials contribute to the production of high-quality lasagna rolls.

Moreover, to help stakeholders determine the economics of a lasagna rolls plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Lasagna rolls are a variation of the traditional lasagna, featuring pasta sheets rolled around a filling of cheese, meat, or vegetables, then baked with sauce and cheese on top. This dish offers a convenient serving method and is often favoured for its appealing presentation. Lasagna rolls can be customised with various ingredients, such as ricotta, spinach, and marinara sauce. The origins of lasagna date back to ancient Greece, where a dish called laganon was made from layers of pasta. The first recorded lasagna recipe appeared in the 14th century in Italy, however, by the 19th century, regional variations emerged, particularly in Naples and Emilia-Romagna. Today, lasagna rolls have become a classic Italian dish.

Lasagna rolls have a cylindrical shape, typically measuring about 3 inches in length and 1 inch in diameter when rolled, with a soft, chewy texture due to the cooked lasagna noodles. The colour of the rolls varies based on the filling, often displaying vibrant hues from ingredients like spinach or tomato sauce. Chemical properties involve a rich composition of macronutrients, including approximately 15-20% protein from cheese and meat fillings, around 30-40% carbohydrates from the pasta, and 10-15% fats from cheese and oils. Additionally, lasagna rolls are often high in vitamins A and C due to vegetable content, while the presence of various herbs and spices contributes to their antioxidant levels.

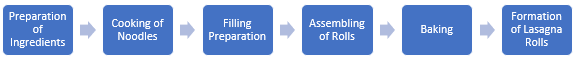

The production process of lasagna rolls begins by gathering essential components: lasagna noodles, typically 9 to 12 sheets, cheese (such as 2 cups of ricotta, 1 cup of mozzarella, and ½ cup of grated Parmesan), sauce (like 2 cups of marinara or alfredo), and optional fillings such as sautéed spinach or cooked ground meat. Next, the cooking of noodles involves boiling the lasagna noodles in salted water for about 8-10 minutes until al dente, then draining and rinsing them with cold water to prevent sticking.

Following this, the filling preparation combines the cheese, vegetables, and seasonings in a bowl until well blended. For the assembly, each noodle is laid flat, approximately 3 inches wide, spread with about ¼ cup of filling, and then tightly rolled up. In the baking stage, a baking dish is prepared by spreading a layer of sauce on the bottom. The rolled noodles are placed seam-side down in the dish, covered with additional sauce and cheese, and baked in a preheated oven at 375°F (190°C) for about 25-30 minutes until heated through and the cheese is bubbly. Lasagna rolls are then cooled to serve.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The lasagna rolls market is driven by the growing trend of home cooking and the demand for convenient meal solutions. For instance, during the pandemic, many families turned to cooking at home, with searches for lasagna recipes increasing by 150% in early 2020. Restaurants like Don Angie in New York City have popularised innovative versions, such as their viral pinwheel lasagna, which combines modern culinary techniques with classic flavours. Additionally, the rise of health-conscious eating has led to increased interest in lasagna roll-ups featuring zucchini and spinach. Government reports also indicate that consumers are increasingly looking for meals that can be prepared in advance and frozen for later use, further driving the popularity of lasagna rolls market.

A detailed overview of production cost analysis that evaluates the manufacturing process of lasagna rolls is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, global eggplant production is projected to reach around 63 million metric tons by 2026, with China as the leading producer, contributing about 65% of the total. In the U.S., annual production is estimated at 142 million pounds, primarily from New Jersey. The Philippines and India are also significant producers, with India expecting around 129.33 lakh tonnes in the 2024-25 season. Market dynamics will be influenced by climate, agricultural practices, and demand, with prices in India projected between INR 1440 to 1630 per quintal at harvest. Overall, the eggplant market shows steady growth, and this increased production can benefit lasagna roll makers by providing a more affordable and abundant ingredient for gluten-free and low-carb options.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a lasagna rolls production plant:

Market Dynamics and Trends: Factors such as launch of innovative variations in lasagna rolls are significantly affecting market conditions in the lasagna rolls sector. Examples include vegetarian roll-ups filled with zucchini and ricotta, crispy fried lasagna rolls with a crunchy coating, and spicy Italian sausage versions that appeal to meat lovers. Unique options like pinwheel lasagna rolls, which feature colourful fillings such as pesto or sun-dried tomatoes are also entering the market. These creative adaptations attract consumers seeking new and exciting culinary experiences. Understanding these demands and trends helps businesses align their production plans in the lasagna rolls market.

Profiling of Key Industry Players: Leading manufacturers such as Barilla, S&B Herba Food Limited, and Inovata Foods are prominently featured in the lasagna rolls report. Recently, the market has seen a surge in innovative culinary creations, including Don Angie's viral pinwheel lasagna, which blends modern techniques with traditional flavours.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in cheese prices significantly impact the costs of lasagna rolls due to several interconnected factors. Cheese is a primary ingredient in lasagna rolls, and any increase in cheese prices directly raises production costs for manufacturers. As of late 2023, the average price of cheese in the U.S. reached approximately USD 2.00 to USD 2.50 per pound, up from around USD 1.50 per pound in 2021. This 33% increase has put pressure on manufacturers.

When cheese prices rise, manufacturers may see their production costs increase by as much as 20-30%, depending on the recipe and the amount of cheese used. Consequently, to maintain profit margins, manufacturers may need to adjust the prices of lasagna rolls by 5-15%, potentially impacting consumer pricing and demand. This dynamic illustrates how fluctuations in cheese prices can ripple through the entire lasagna rolls market, affecting both producers and consumers alike. Understanding these elements is essential for stakeholders to navigate market trends effectively.

Establishing a lasagna rolls manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the lasagna rolls industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share