Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Jalapeno Poppers Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a jalapeno poppers plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for jalapeno poppers is increasing due to the rising popularity of spicy and flavourful foods among consumers. As culinary preferences evolve, more people are seeking bold flavours, leading to a surge in the consumption of spicy snacks like jalapeno poppers. This trend is evident in the growing number of fast-casual dining establishments incorporating jalapeno poppers into their menus, such as Jack in the Box, Sonic, and Wienerschnitzel, which offer unique variations of this popular appetizer. Additionally, the expansion of global food culture plays a significant role in this demand. The increasing interest in Mexican and Tex-Mex cuisines, where jalapeno poppers are a staple, has contributed to their popularity. Chains like Church's Chicken and Carl's Jr. have also included jalapeno poppers as a featured item.

Other elements to consider while establishing a jalapeno poppers plant include raw material sourcing, workforce planning, and packaging. The production of jalapeno poppers relies on several key raw materials, such as jalapeno peppers, cream cheese, and bacon. Jalapeno peppers are typically grown in regions with warm climates, such as Mexico and the southern United States, where they thrive in the heat and can be harvested year-round. Cream cheese is manufactured by dairy processing companies, often sourced from local dairy farms that provide high-quality milk. Bacon, on the other hand, is produced by meat processing plants that source pork from farms across the country, ensuring a steady supply of this essential ingredient.

Moreover, to help stakeholders determine the economics of a jalapeno poppers plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Jalapeno poppers are an appetizer featuring jalapeno peppers stuffed with cheese, often cream cheese or cheddar, and sometimes mixed with spices or meats. The peppers are typically breaded and deep-fried, resulting in a crispy exterior that contrasts with the creamy filling. This dish balances the heat of the jalapeno with the coolness of the cheese, making it a favourite at parties and gatherings. The jalapeno pepper is native to Mexico, with its name meaning "from Xalapa," the capital of Veracruz. The modern version of jalapeno poppers likely originated in Texas around 1972, evolving from traditional stuffed peppers like chiles rellenos. The term "jalapeno popper" was trademarked in 1992, leading to widespread popularity across the United States.

Jalapeno poppers measure between 5 to 10 cm in length and have a diameter of about 2 to 3 cm. Their vibrant green or red colour varies with ripeness, and they feature a crispy exterior from deep frying, while the interior is creamy, often containing 30 to 50 grams of cheese. Chemically, jalapeno contains capsaicin, which gives them heat, typically ranging from 4,000 to 8,500 Scoville heat units. Nutritionally, they average about 250 calories per 100g, comprising approximately 39% carbohydrates (around 25g), 50% fat (about 12g), and 11% protein (roughly 3g). They also provide vitamins A (about 1,000 IU) and C (around 10 mg).

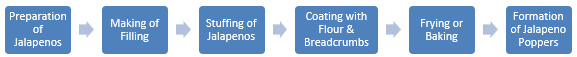

The production process of jalapeno poppers begins with gathering of fresh jalapenos, cheese, breadcrumbs, and seasonings. Next, the jalapenos are prepared by trimming the stems and slicing them in half lengthwise. Optionally, they can be blanched in boiling water for about three minutes to soften their texture. After blanching, the seeds and membranes are carefully removed to reduce the heat. The filling is then made by mixing cheese with spices and other ingredients in a bowl before stuffing each jalapeno half with this mixture. The stuffed jalapenos are coated in a flour-water paste, followed by rolling them in breadcrumbs to create a crispy exterior. Finally, they are either deep-fried at around 365°F or baked at 400°F until golden brown.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The jalapeno poppers market is influenced by various applications and drivers, which reflects changing consumer preferences and culinary trends. The growing popularity of spicy snacks has led to the inclusion of jalapeno poppers on menus across numerous restaurant chains, such as Carl's Jr., Arby's, and Sonic, where they are featured prominently as appetizers. Additionally, the rise of casual dining establishments has paved the way for innovative variations, such as bacon-wrapped jalapeno poppers at Two Bros BBQ Market in Texas. The increasing trend towards convenience foods has also led to the emergence of frozen options from brands like Mr. Munchies and ITC Master Chef, catering to consumers seeking quick or ready-to-eat meal solutions. The fusion of traditional Mexican cuisine with modern American tastes continues to drive interest in jalapeno poppers, making them a staple in both home cooking and foodservice sectors.

A detailed overview of production cost analysis that evaluates the manufacturing process of jalapeno poppers is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a jalapeno poppers production plant:

Market Dynamics and Trends: Factors such as favorable jalapeno production across countries are significantly affecting market conditions in the jalapeno poppers sector. North America, particularly Mexico and the United States, remains a leading producer and consumer of jalapenos. In 2023, Mexico's Ministry of Agriculture reported a record hot pepper harvest of 3.68 million metric tons, with jalapenos accounting for approximately 0.9 million metric tons of this yield. This robust production supports both domestic consumption and export capabilities, ensuring a steady supply for food service and processing industries. In February 2024 alone, there were 432 jalapeno pepper export shipments, marking an 82% year-on-year growth compared to February 2023. This expanding global interest in Mexican cuisine and the health benefits associated with jalapenos further enhance market dynamics, positioning jalapeno poppers as a popular choice among consumers seeking bold flavours and unique culinary experiences. Understanding these trends helps businesses align their production plans in the jalapeno poppers market.

Profiling of Key Industry Players: Leading manufacturers like L & M Companies, Can-Am Pepper Company Ltd, and Global Green Company Limited are included in the jalapeno poppers report, highlighting their significant roles in the production and supply of jalapeno peppers. Recently, in August 2024, Good Foods, known for its "better-for-you dips and guacamole," introduced a new seasonal dip flavour called Cranberry Jalapeno, crafted with fresh jalapenos. The expansion of these manufacturers' product lines demonstrates the increasing popularity of jalapeno-based products in the market.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in jalapeno poppers prices are influenced by several factors, including raw material costs, supply chain dynamics, and consumer demand. The prices of key ingredients such as jalapeno peppers, cream cheese, and breadcrumbs can vary significantly based on seasonal availability and agricultural conditions. For instance, if adverse weather affects jalapeno crops in major producing regions like Mexico and the southern United States, it can lead to reduced supply and increased prices. Additionally, supply chain disruptions, such as transportation delays or increased shipping costs, can also impact the final price of jalapeno poppers; for example, rising fuel prices may increase logistics costs, which are then passed on to consumers. Consumer demand plays a crucial role as well; during peak seasons for parties and gatherings, such as the Super Bowl or summer barbecues, the demand for snacks like jalapeno poppers tends to spike, leading to temporary price increases in the market. These factors contribute to the fluctuations observed in jalapeno popper prices.

Establishing a jalapeno poppers manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of a jalapeno poppers manufacturing facility must comply with various regulatory frameworks that govern production standards. Key regulations include those set by the Food and Drug Administration (FDA), which ensures food safety and labelling requirements through Current Good Manufacturing Practices (CGMP). Facilities must also obtain necessary state and local permits, including health department inspections. If the facility processes meat or dairy, compliance with United States Department of Agriculture (USDA) standards is required. Additionally, manufacturers must implement rigorous quality assurance protocols to ensure that all ingredients meet safety standards, including regular testing for contaminants. Compliance with these regulations is essential for ensuring the safety and quality of jalapeno poppers.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the jalapeno poppers industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share