Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Isopropylamine Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing an isopropylamine plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for isopropylamine is increasing due to the need for enhanced food security driven by a growing global population, which is projected to reach approximately 9.7 billion by 2050. This rising population necessitates improved agricultural practices and effective crop protection solutions, leading to a higher demand for agrochemicals that use isopropylamine as a critical intermediate. Isopropylamine is essential in the production of herbicides like glyphosate and insecticides such as imidacloprid, which are crucial for maintaining crop yields.

Other elements to consider while establishing an isopropylamine plant include raw material sourcing, workforce planning, and packaging. The production of isopropylamine relies on several key raw materials, such as isopropyl alcohol and ammonia. Isopropyl alcohol is typically produced through the hydration of propylene, while ammonia is primarily derived from the Haber-Bosch process, which produces ammonia from nitrogen and hydrogen gases. These materials ensure efficient production of isopropylamine.

Moreover, to help stakeholders determine the economics of an isopropylamine plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

However, challenges such as supply chain disruptions and volatile raw material costs may threaten supply stability for isopropylamine production. Events like severe weather conditions, geopolitical tensions, or logistical issues can lead to delays in the procurement of essential raw materials such as isopropyl alcohol and ammonia. To combat this, manufacturers of isopropylamine can diversify their supplier base and invest in advanced inventory management systems. By establishing relationships with multiple suppliers across different regions and employing technologies that enhance visibility and forecasting, manufacturers can mitigate supply chain risks and ensure a more stable production process.

Isopropylamine, also known as monoisopropyl amine or 2-propylamine, is a hygroscopic, colourless liquid with an ammonia-like odour. It has a boiling point of 32 °C (90 °F) and is miscible with water, making it an important intermediate in the chemical industry. Isopropylamine is widely used in the production of herbicides and insecticides, including formulations such as atrazine and glyphosate, which are essential for modern agriculture. Additionally, it serves as a solvent and a neutralising agent in the synthesis of pharmaceuticals and surfactants.

Isopropylamine was first made in the early 20th century, with significant advancements in its production methods occurring during the 1930s. By the mid-20th century, its importance in agrochemicals became evident, leading to increased industrial demand. Today, approximately 50,000 tons of isopropylamine are produced annually in the U.S., reflecting its versatility and widespread use across multiple sectors, including agriculture, pharmaceuticals, and chemical manufacturing.

Isopropylamine is a hygroscopic, colourless liquid with an ammonia-like odour, known by a molecular formula of C3H9N and a molecular weight of 59.1 g/mol. Its physical properties include a boiling point of approximately 33-34 °C (91-93 °F), a melting point of -95.2 °C (-139.4 °F), and a specific gravity of about 0.691 at 20 °C. Isopropylamine is miscible with water and exhibits a flash point of -35 °C (-31 °F), indicating its flammability. It acts as a weak base with a pKa value of 10.63, making it reactive in various organic synthesis processes, including alkylation and acylation.

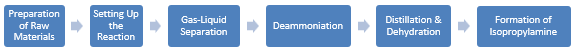

The production process of isopropylamine begins with the preparation of raw materials, primarily acetone, hydrogen, and ammonia. The first step involves preheating this mixture to the required reaction temperature. The preheated mixture is then fed into a fixed-bed reactor containing a nickel-based catalyst, where hydrogen aminating reactions occur at controlled temperatures ranging from 110 to 150 °C. After the reaction, the product is cooled and passed through a gas-liquid separator to separate unreacted gases from the liquid phase. The liquid phase is then transferred to a de-ammoniation tower to remove any excess ammonia. Following this, the resulting solution rich in isopropylamine undergoes distillation to isolate the final product. Finally, any remaining water is removed in a dehydration tower, yielding pure isopropylamine.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The most common industrial method for producing isopropylamine (C3H9N) is through the reaction of ammonia (NH3) with propylene (C3H6) in a process called aminomethylation. This reaction typically occurs in the presence of a catalyst under high pressure and temperature.

Step 1: Preparation of the Reactants

Propylene (C3H6) is obtained as a by-product from the petroleum refining process or by cracking hydrocarbons. Ammonia (NH3) is typically sourced from natural gas, where nitrogen and hydrogen combine in the Haber process.

Step 2: Aminomethylation Reaction

The primary reaction involves the following steps:

Direct Ammonia Reaction with Propylene:

C3H6 + NH3 → C3H9N

This reaction produces isopropylamine (C3H9N) as the main product. The process typically uses a solid or liquid catalyst, such as a transition metal catalyst, under high pressure (30-100 atm) and moderate temperatures (200-300°C).

Formation of Secondary and Tertiary Amines (side reactions):

Depending on the conditions, there can also be the formation of diisopropylamine (C6H15N) and triisopropylamine (C9H21N), which are secondary and tertiary amines, respectively.

Secondary amine formation (diisopropylamine):

C3H6 + C3H9N → C6H15N

Tertiary amine formation (triisopropylamine):

C3H6 + C6H15N → C9H21N

Step 3: Purification

The product mixture contains isopropylamine along with any by-products (secondary and tertiary amines). The product is purified through distillation to isolate isopropylamine.

The isopropylamine market is driven by its extensive applications across various industries, particularly in agriculture, pharmaceuticals, and manufacturing. It serves as a vital intermediate in the production of herbicides and pesticides, including well-known chemicals like glyphosate and atrazine, which are essential for modern farming practices. The U.S. production of isopropylamine is substantial, reflecting its significant industrial demand, with estimates suggesting several tens of thousands of tons produced each year. Additionally, it is used in the synthesis of pharmaceuticals such as propranolol and diisopropylamine dichloroacetate, showcasing its importance in healthcare. Government initiatives such as the Environmental Quality Incentives Program (EQIP) and the Conservation Stewardship Program (CSP) promote sustainable agricultural practices that often rely on chemicals like isopropylamine, enhancing market growth. Furthermore, the Inflation Reduction Act has allocated funding to support climate-smart agriculture, which encourages the use of eco-friendly pesticides and herbicides. Recent reports indicate increasing interest in its use as a solvent and emulsifier in various chemical processes, reinforcing its relevance in diverse applications.

A detailed overview of production cost analysis that evaluates the manufacturing process of isopropylamine is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for an isopropylamine production plant:

Market Dynamics and Trends: Factors such as expansion of pharmaceutical industry are significantly affecting market conditions in the isopropylamine sector. The pharmaceutical industry significantly contributes to the demand for isopropylamine, as it is used in the synthesis of important medications, including penicillin and streptomycin, both vital antibiotics. The increasing prevalence of infectious diseases and the growing focus on healthcare further drive this demand. Moreover, the expansion of the rubber and plastics industries also uses isopropylamine in manufacturing rubber accelerators and other chemical intermediates. This multifaceted demand underscores the importance of isopropylamine in supporting global agricultural productivity and healthcare advancements. Understanding these demands and trends helps businesses align their production plans in the isopropylamine market.

Profiling of Key Industry Players: Leading manufacturers like DFPCL and BASF are included in the isopropylamine report. Recently, DFPCL announced plans to expand its isopropyl alcohol production capacity, which directly supports the synthesis of isopropylamine. Additionally, BASF SE is engaged in the development of isopropylamine applications.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in isopropylamine prices are influenced by raw material costs, supply chain dynamics, and market demand. The availability and pricing of key raw materials, such as isopropyl alcohol and ammonia, directly impact production costs. For instance, any disruptions in the supply of these inputs due to geopolitical tensions or natural disasters can lead to significant price volatility. Additionally, fluctuations in demand from downstream industries, particularly the agrochemical and pharmaceutical sectors, play a crucial role. For example, during periods of increased agricultural activity or pharmaceutical production, heightened demand for isopropylamine can drive prices up. Conversely, when demand softens, prices may decline. Recent trends indicate that supply shortages around seasonal events, such as the Lunar New Year, have also contributed to price increases. Understanding these elements is essential for stakeholders to navigate market trends effectively.

Establishing an isopropylamine manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of an isopropylamine manufacturing facility must comply with various regulatory frameworks that govern production standards. Key regulations include those set by the Environmental Protection Agency (EPA), which mandates adherence to standards for volatile organic compounds (VOCs) under 40 CFR 60.489. This requires that all newly constructed or modified units implement the best systems for continuous emission reduction to lower equipment leaks.

Additionally, isopropylamine is regulated by the Occupational Safety and Health Administration (OSHA), which enforces exposure limits such as an 8-hour time-weighted average (TWA) of 5 ppm and a 15-minute short-term exposure limit (STEL) of 10 ppm. Compliance with these regulations ensures that manufacturers maintain safe working conditions and minimise environmental impacts during production. Furthermore, the Food and Drug Administration (FDA) regulates the use of isopropylamine salts in food-related applications. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the isopropylamine industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share