Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Isoborneol Flakes Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing an isoborneol flakes plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for isoborneol flakes is experiencing significant growth, primarily driven by their diverse applications across various industries. In the personal care sector, isoborneol flakes are sought after for their fragrance and cooling properties, making them a crucial ingredient in perfumes, lotions, and soaps. Additionally, their therapeutic properties, such as antiviral, antibiotic, and anti-inflammatory effects, have increased their usage in pharmaceuticals for treating respiratory issues and heart disease. The natural insect repellent qualities of isoborneol flakes also make them an attractive option for safe and effective pest control, particularly in regions with high insect activity.

Other elements to consider while establishing an isoborneol flakes plant include raw material sourcing, workforce planning, and packaging. The production of isoborneol flakes relies on several key raw materials, such as borneol, which are sourced from natural plant materials, particularly from the camphor tree and various species within the Lamiaceae family. Borneol is typically extracted through steam distillation of plant parts, including leaves, bark, and flowers, ensuring high purity and quality for subsequent processing into isoborneol flakes.

Additionally, the manufacturing process may involve other chemicals for purification and formulation, which are sourced from established chemical suppliers. The reliance on these natural and chemical sources underscores the importance of sustainable harvesting practices and quality control to maintain the integrity of the final product.

Moreover, to help stakeholders determine the economics of an isoborneol flakes plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Iso Borneol flakes are a refined form of the bicyclic organic compound borneol, known for their white crystalline structure and refreshing scent. They are widely used in traditional medicine for their analgesic, anti-inflammatory, and antispasmodic properties, providing relief from pain and inflammation. Additionally, these flakes find applications in the fragrance industry, cosmetics, insect repellents, and food flavouring due to their pleasant aroma and potential health benefits.

Iso Borneol has been used in traditional Chinese and Ayurvedic medicine for centuries. Its medicinal properties have been documented since ancient times, particularly for treating inflammation and pain. The compound is derived from camphor and has evolved into a significant ingredient in modern therapeutic and industrial applications.

Isoborneol flakes are a crystalline form of the organic compound isoborneol, notable for their distinct properties. Physically, they appear as white or cloudy white crystals with a melting point ranging from 212 to 214 °C (414 to 417 °F) and a molecular weight of approximately 154.25 g/mol. They emit a characteristic camphor-like scent that provides a cooling effect and are soluble in organic solvents like ethanol, but insoluble in water. Isoborneol has the formula C10textH18O and is identified by the CAS number 124-76-5. Its boiling point is around 212 °C (413.6 °F) at standard atmospheric pressure, making it useful in various applications across the fragrance, food, and pharmaceutical industries.

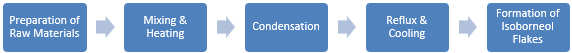

The production process of isoborneol flakes begins with the preparation of raw materials, primarily using a camphene mixture (over 95% camphene) combined with a solvent such as Virahol and water in a specific ratio. The next step involves mixing these components in a distillation kettle. The mixture is then heated to reach the azeotropic temperature, typically between 60 and 80 °C, allowing for distillation where the product rises to the top of the kettle. The distillate is condensed using an overhead condenser, and then refluxed back into the distillation kettle through a fixed bed catalytic reactor. After approximately eight hours, a sample of the reactant is taken for analysis, and heating is stopped once the camphene content drops to 3% or lower. Finally, the reactant is cooled to below 40 °C before discharging the final isoborneol product.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

Isoborneol, a secondary alcohol, is typically produced through the reduction of camphor. The reduction is often carried out using reducing agents such as sodium borohydride (NaBH4) or lithium aluminium hydride (LiAlH4). This process results in the formation of isoborneol in the form of crystals or flakes.

The primary reaction in the production of isoborneol is the reduction of camphor to isoborneol.

Reduction of Camphor: C10H16O (camphor) + H2 → C10H18O (isoborneol)

Process Overview:

1. Preparation of Reactants:

Camphor (C10H16O) is typically obtained from natural sources such as the camphor tree (Cinnamomum camphora) or synthesized via the terpenoid pathway. A suitable reducing agent such as sodium borohydride (NaBH4) or lithium aluminium hydride (LiAlH4) is prepared for the reduction reaction.

2. Reduction Reaction:

The reduction of camphor is carried out by introducing it to the reducing agent in an appropriate solvent under mild conditions (room temperature or slightly elevated temperature). The reaction results in the formation of isoborneol, a crystalline secondary alcohol.

3. Crystallisation:

After the reduction, the reaction mixture is cooled, and isoborneol crystallises out of the solution. The crystalline product is filtered to separate the isoborneol flakes from the reaction mixture.

4. Purification:

The isoborneol flakes are further purified through recrystallisation techniques to remove any impurities or unreacted materials.

5. Final Product:

The final purified isoborneol flakes are collected and dried.

Isoborneol flakes have diverse applications across various industries. They are prominently used in the fragrance industry for perfumes such as Chanel No. 5 and Acqua di Gio, as well as cosmetics like Lush's range of products, due to their pleasant aroma, contributing to the growing preference for natural and organic ingredients in personal care products. In the pharmaceutical sector, isoborneol is found in medicines like Yao Tong Pian, which is used for pain relief, and various topical formulations that provide analgesic and anti-inflammatory effects, aiding in pain relief and treatment of conditions like arthritis. The insect repellent market also benefits from isoborneol's natural repellent properties, making it a key ingredient in eco-friendly pest control solutions. Government regulations promoting sustainable practices further drive market growth by encouraging the use of renewable resources in manufacturing. Additionally, ongoing research highlights isoborneol's potential as a cleaning agent and its applications in aromatherapy, enhancing its appeal across multiple sectors.

A detailed overview of production cost analysis that evaluates the manufacturing process of isoborneol flakes is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for an isoborneol flakes production plant:

Market Dynamics and Trends: Factors such as cultural and traditional significance of the product are significantly affecting market conditions in the isoborneol flakes sector. Isoborneol flakes hold significance in religious rituals and traditional remedies where they are believed to purify the environment and promote relaxation. Isoborneol, often referred to as Bhimseni Kapoor, is commonly used in Hindu ceremonies, such as Aarti, where its aromatic properties are thought to create a sacred atmosphere conducive to spiritual reflection. The expansion of global supply chains and advanced manufacturing technologies have streamlined the production and distribution of isoborneol flakes, improving their availability in the market. With versatile applications in personal care products, pharmaceuticals, and aromatherapy, the demand for isoborneol flakes is projected to continue its upward trend. This increasing consumer awareness of natural ingredients further contributes to their growing popularity across different industries. Understanding these demands and trends helps businesses align their production plans in the isoborneol flakes market.

Profiling of Key Industry Players: Leading manufacturers like Saptagir Camphor Limited and Balaji Traders are included in the isoborneol flakes report. Recently, Saptagir Camphor Limited has expanded its production capabilities, enhancing its supply of isoborneol flakes to meet the growing demand driven by the cosmetics and pharmaceutical industries. Additionally, Balaji Traders has increased its export activities, reflecting the rising global interest in natural ingredients for personal care and traditional remedies.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Establishing an isoborneol flakes manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of an isoborneol flakes manufacturing facility must comply with various regulatory frameworks that govern production standards. Key regulations include those outlined by the Environmental Protection Agency (EPA), which requires adherence to safety and environmental standards to reduce emissions and waste during production. Compliance with the Occupational Safety and Health Administration (OSHA) guidelines is also essential, ensuring safe working conditions for employees handling isoborneol, which can be classified as a flammable material.

Additionally, manufacturers must follow quality assurance protocols that align with industry standards, such as those set by the International Organization for Standardization (ISO). For instance, achieving ISO 9001 certification can help ensure consistent quality management systems are in place. Furthermore, specific certifications related to the chemical industry may be necessary, depending on the intended applications of the isoborneol flakes, especially in food and pharmaceutical sectors where strict safety regulations apply. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the isoborneol flakes industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share