Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Instant Pho Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing an instant pho plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

One significant factor fuelling demand for instant pho is the growing preference for convenient meal options. Instant pho offers a quick, easy, and delicious solution for busy individuals and families. According to the Food Safety and Standards Authority of India (FSSAI), over 60% of urban consumers prefer instant meals due to their fast preparation time. Another driving factor is the rise in health consciousness among consumers. Many instant pho products are made with natural ingredients and are free from artificial preservatives. For example, a study by the Ministry of Health and Family Welfare found that 70% of consumers are willing to pay a premium for healthier instant meal options.

Other elements to consider while establishing an instant pho plant include raw material sourcing, workforce planning, and packaging. The production of instant pho relies on several key raw materials, such as rice noodles, broth bases, and aromatic herbs. Rice noodles are typically obtained from Vietnam and Thailand, where rice cultivation is integral to the culture and economy. Broth bases often contain beef, chicken, or vegetable extracts, which are sourced from Australia, India, and the United States. Aromatic herbs like basil, cilantro, and green onions are crucial for the authentic pho flavour and are sourced from Southeast Asian countries, notably Vietnam and Thailand. These raw materials ensure the final instant pho product retains its authentic taste and meets safety standards.

Moreover, to help stakeholders determine the economics of an instant pho plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Instant pho, a convenient version of the traditional Vietnamese noodle soup, has gained immense popularity due to its quick preparation and authentic flavours. Originating in the early 20th century, pho itself was developed in northern Vietnam during French colonial times, evolving from local culinary food that incorporated beef and rice noodles. Instant pho emerged as a response to the global demand for fast, flavourful meals, allowing consumers to enjoy this beloved dish with minimal effort. Today, it is widely available in various forms, including cups and packets.

Instant pho consists of rice noodles (about 60-70% of the product), seasonings, and dehydrated vegetables or proteins, packaged in cups or packets for easy preparation. The noodles generally contain around 75-80 grams of carbohydrates per serving, with fat content varying between 5-10 grams, while protein content is usually around 4-6 grams. Chemically, instant pho has a pH range of 6.0 to 7.5, indicating mild acidity. Its formulation often includes preservatives and flavour enhancers like monosodium glutamate (MSG), which can contribute to sodium levels that may exceed 800-1,200 mg per serving.

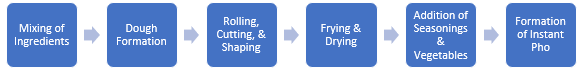

The production process of instant pho begins with flour storage, where high-quality wheat flour is kept in silos and transported to the manufacturing facility. In the mixer, water and oil are added to the flour to create a dough, which is then rolled into sheets. These sheets are cut into strips, which are shaped into noodle discs. The noodles are then fried in oil at a controlled temperature. Next, the noodles undergo a drying process to remove moisture, ensuring a long shelf life. Next, seasonings and dehydrated vegetables are added, often including spices like garlic, onion, and herbs. The prepared noodles are then sealed, labelled, and placed in cups or packets.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The instant pho market is experiencing significant growth driven by several key factors. As a convenient meal option, instant pho caters to the busy lifestyles of consumers, especially among the working population, which has reached approximately 14.5 million employed individuals in Australia as of September 2024, reflecting a 0.3% increase from the previous month. Reports indicate that over 60% of consumers prefer ready-to-eat meals, highlighting a shift towards convenience foods amidst hectic schedules. Brands like Nissin and Mama have successfully introduced instant pho products that appeal to vegetarian and gluten intolerant consumers.

Additionally, the rising trend of plant-based diets is influencing product development, with manufacturers like Annie Chun’s offering vegan instant pho to meet consumer demand for healthier choices. The popularity of instant pho is also fuelled by its adaptability in various culinary contexts, making it a staple in households and restaurants. The instant pho market is also being driven due to the launch of new products in 2024. For example, Sa Giang recently introduced its Instant Pho Saigon Recipe, which captures the authentic flavours of traditional Vietnamese pho. Additionally, Snapdragon Foods has launched its own line of instant pho bowls, which features authentic Vietnamese flavours and no artificial additives.

A detailed overview of production cost analysis that evaluates the manufacturing process of instant pho is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, Vietnamese cuisine's global popularity, particularly dishes like pho, has boosted the country's economy. Accolades like "Asia’s Best Culinary Destination" and "World’s Leading Culinary City" have increased tourism and exports. Instant pho makers can benefit from this trend as global demand is expected to rise further. Companies like Nhịp Sống and Vifon leverage Vietnam's culinary reputation, exporting instant pho to meet international demand.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for an instant pho production plant:

Market Dynamics and Trends: Factors such as the increased demand for international and exotic cuisines are significantly impacting market conditions in the instant pho sector. Consumers appreciate the convenience of enjoying Vietnamese cuisine at home, making instant pho a popular choice. The National Restaurant Association reported that ethnic foods, including Asian cuisine, are among the top trends for 2025. This trend is reflected in the rise of popular instant pho brands like Mama, known for their authentic flavours and quick preparation time. Additionally, Sai Gon offers gluten-free and organic options. By understanding these demands and trends, businesses can align their production plans to capture a larger market share.

Profiling of Key Industry Players: Leading manufacturers like Nhịp Sống, Vifon, and Acecook Vietnam are included in the instant pho report. Recently, PhoLicious, featured on Shark Tank, secured a deal with Kevin O'Leary to expand their distribution and manufacturing capabilities. This expansion allows PhoLicious to scale their operations and bring their authentic Vietnamese taste to a wider audience. Similarly, Acecook Vietnam is innovating with new flavours and packaging that cater to evolving consumer preferences.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Prices of rice noodles, broth bases, and aromatic herbs fluctuate instant pho prices. For instance, any disruption in supply chains or adverse weather conditions affecting rice production can lead to increased prices. Production technology also impacts costs; advancements in technology can reduce production expenses, but the initial investment might raise prices temporarily. Economic conditions, such as inflation and exchange rates, also affect overall costs, making imported raw materials more expensive. Consumer demand influences price fluctuations as well; a surge in demand can lead to higher prices. Lastly, global trade policies, including tariffs and import-export regulations, impact the costs associated with production and sourcing, contributing to price volatility. These factors collectively create a dynamic pricing environment for instant pho.

Establishing an instant pho manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of an instant pho manufacturing facility must comply with various regulatory frameworks that govern production standards. Food Safety and Standards Authority of India (FSSAI) sets the regulations for food safety and quality, requiring manufacturers to adhere to stringent hygiene practices and labelling requirements. Additionally, environmental regulations mandate proper waste management and the use of sustainable practices to reduce environmental impact. Customs and import-export regulations also play a role, as they govern the sourcing of raw materials from different countries. Compliance with these regulatory frameworks ensures the production of safe, high-quality instant pho while adhering to environmental and trade standards.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the instant pho industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share