Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Grape Pulp Based Citric Acid Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a grape pulp based citric acid plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for citric acid derived from grape pulp is rising due to increasing consumer preference for natural and clean-label ingredients. Health-conscious consumers view citric acid, a natural preservative found in citrus fruits, as a safer alternative to synthetic additives. The global citric acid market is projected to grow due to the food and beverage industry’s shift towards natural ingredients.

Using grape pomace, a byproduct of winemaking, aligns with sustainability goals by reducing waste and promoting eco-friendly practices. For example, beverages like Coca-Cola's Minute Maid and PepsiCo's Tropicana increasingly incorporate grape-derived citric acid to enhance flavour and extend shelf life. Regulatory support for natural ingredients further encourages manufacturers to explore sustainable sources like grape pulp. This trend not only meets consumer demands but also fosters a more sustainable food system, benefiting both producers and environmentally conscious consumers.

Other elements to consider while establishing a grape pulp based citric acid plant include raw material sourcing, workforce planning, and packaging. The production of grape pulp-based citric acid relies on several key raw materials, primarily grape pomace, which is sourced from the winemaking process. Grape pomace, the residue left after juice extraction, constitutes about 16% of the original fruit and is rich in carbohydrates, making it an ideal substrate for citric acid production using microbial fermentation, particularly with the fungus Aspergillus niger. In addition, other raw materials such as sucrose or molasses can be added to enhance fermentation. Molasses, a byproduct of sugar refining, is widely used due to its low cost and high sugar content (40-55%). These materials are typically sourced from sugarcane or beet processing facilities. The combination of these substrates allows for efficient citric acid production.

Moreover, to help stakeholders determine the economics of a grape pulp based citric acid plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Grape pulp, or grape pomace, is the solid residue left after pressing grapes for juice or wine. This byproduct is rich in sugars and organic acids, which makes it an excellent substrate for the microbial fermentation of citric acid. The fermentation process involves optimising conditions such as pH (typically around 3-5), temperature (25-30°C), and nutrient availability to increase yields, which can reach up to 100 grams per litre of fermentation broth. Using grape pulp not only reduces waste in the winemaking industry but also provides a sustainable method for producing citric acid, which is widely used as a natural preservative, flavouring agent, and pH regulator in food and beverages. Citric acid was first isolated in 1784 by Swedish chemist Carl Wilhelm Scheele from lemon juice. The late 19th century marked the beginning of industrial production in 1890, with citrus fruits as the primary source. A significant shift occurred in 1917 when Aspergillus niger was employed for citric acid production, enabling large-scale manufacturing, and transforming the industry.

Grape pulp-based citric acid is a colourless and odourless crystalline solid that typically appears as a white powder at room temperature. The molecular formula is C6H8O7, with a molar mass of 192.13 g/mol and a density of approximately 1.665 g/cm3. It has a melting point of 153°C and begins to decompose at temperatures above 175°C, releasing carbon dioxide and water. This citric acid is classified as a weak organic acid and is triprotic, meaning it can donate three protons, with pKa values of approximately 3.13, 4.76, and 6.40 for its three dissociation steps. Its solubility in water is notably high, at about 59 g per 100 mL at room temperature (25°C), and it is also soluble in alcohols like ethanol. These properties make citric acid useful in food preservation, flavour enhancement, and as a pH regulator.

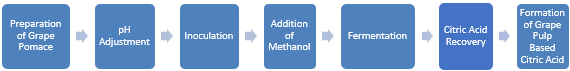

The production process of grape pulp-based citric acid begins with the collection of grape pomace. The pomace is then prepared by grinding it to an average particle size of less than 0.25 inches and adjusting its moisture content to between 45% and 75%. Next, the pH is adjusted to below 4.0, typically using hydrochloric or sulfuric acid if necessary. Following this, the pomace is inoculated with a spore inoculum of Aspergillus niger, at a concentration of 1×105 to 1×107 viable spores. To enhance citric acid production, methanol is added at a concentration of 1.0% to 3.5% (v/w). The mixture undergoes fermentation in solid-state conditions at temperatures ranging from 25°C to 30°C for approximately 4-5 days. After fermentation, citric acid is recovered from the fermented mixture using water, followed by analysis for residual sugar and citric acid content. Finally, the citric acid is purified and packaged.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

Grape pulp-based citric acid has diverse applications across multiple industries, driven by its effectiveness as a natural preservative and flavour enhancer. In the food and beverage sector, it is commonly found in popular soft drinks such as Coca-Cola Fanta Grape, which uses citric acid to enhance taste and maintain freshness, as well as in Welch's grape juice, where it contributes to the tart taste and antioxidant properties. Citric acid is also prevalent in skincare products like Neutrogena's Oil-Free Acne Wash, where it serves as a pH balancer and exfoliant, and in medications such as Alka-Seltzer, where it acts as a buffering agent. Furthermore, its role as a chelating agent in cleaning products underscores its versatility. Government reports highlighting need for waste reduction has spurred interest in using grape pomace, a byproduct of winemaking, for citric acid production.

A detailed overview of production cost analysis that evaluates the manufacturing process of grape pulp based citric acid is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a grape pulp based citric acid production plant:

Market Dynamics and Trends: Favorable grape production conditions are significantly impacting the market for grape pulp-based citric acid. In 2024, various states in the U.S. and other countries are expected to report substantial grape harvests, contributing to the availability of grape pomace for citric acid production. California, as the largest producer, is projected to yield approximately 4.0 million tons of grapes, accounting for nearly 90% of U.S. grape production. Washington is anticipated to produce around 300,000 tons, while New York is expected to yield about 200,000 tons, primarily from its diverse wine grape varieties. Internationally, countries like Italy and Spain are also expected to have strong harvests, with Italy producing around 2.0 million tons and Spain approximately 1.5 million tons of grapes. These favourable conditions not only enhance the availability of raw materials for citric acid production but also help stabilise prices in the grape pulp-based citric acid sector. Understanding these demands and trends helps businesses align their production plans in the grape pulp based citric acid market.

Profiling of Key Industry Players: Leading manufacturers in the grape pulp-based citric acid sector include Archer Daniels Midland Company, Cargill, Incorporated, Tate & Lyle PLC, and Jungbunzlauer Suisse AG. These companies are at the forefront of citric acid production, leveraging various raw materials and innovative fermentation techniques to enhance yield and sustainability.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in grape pulp-based citric acid prices are influenced by changes in raw material costs, supply-demand dynamics, and geopolitical factors. The price of citric acid in the United States reached 906 USD/MT in Q2 2024, reflecting the impact of rising production costs and supply chain challenges. In Q1 2024, prices were affected by slowdowns in production and increased freight costs due to geopolitical tensions, with prices rising to 893 USD/MT.

Additionally, regional supply constraints and seasonal demand fluctuations play a significant role. In South Korea, citric acid prices experienced a notable increase due to heightened production costs and supply limitations from China, reaching 787 USD/MT in June 2024. These dynamics contribute to price volatility in the grape pulp-based citric acid market.

Establishing a grape pulp based citric acid manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of a grape pulp-based citric acid manufacturing facility must comply with various regulatory frameworks that govern production standards. These regulations include adherence to the CODEX standards for food safety, which dictate permissible levels of food additives, including citric acid and malic acid, and require compliance with Good Manufacturing Practices (GMP) to ensure product quality and safety.

Additionally, the facility must meet local food safety regulations, such as those set forth by the Food Safety and Standards Authority of India (FSSAI), which outline specific requirements for fruit and vegetable products, including acidity levels and permissible contaminants. Environmental regulations also play a critical role, requiring facilities to manage waste effectively and minimise their ecological footprint. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the grape pulp based citric acid industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share