Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Glycerin Monostearate Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a glycerin monostearate plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for glycerol monostearate (GMS) is increasing due to the growing demand for processed and convenience foods. As lifestyles become busier, consumers are increasingly seeking ready-to-eat meals, baked goods, and snacks. GMS serves as an effective emulsifier and stabiliser in products like ice cream, margarine, and baked goods, which enhances texture, consistency, and shelf life. For instance, in ice cream production, glycerol monostearate helps prevent the formation of ice crystals, resulting in a smoother texture. As ice cream production increases, demand for glycerol monostearate is expected to grow. In 2023, U.S. ice cream makers produced around 1.30 billion gallons of ice cream, which contributed USD 11.4 billion to the U.S. economy.

Another significant factor contributing to the rising demand for glycerol monostearate is the shift towards clean-label and natural ingredients. Consumers are becoming more health-conscious and scrutinising ingredient lists for artificial additives. GMS, derived from vegetable sources, aligns well with this trend as it is perceived as a natural alternative to synthetic emulsifiers. This shift has prompted manufacturers in food and cosmetics, to innovate formulations that incorporate GMS to meet consumer expectations for transparency and quality. Glycerol monostearate (GMS) is commonly found in various personal care products, including creams, lotions, and hair care formulations, where it enhances texture and stability. Brands like Nivea use GMS for its moisturising creams; L'Oréal incorporates it in hair conditioners and styling products; and Cetaphil uses it in skincare formulations. Additionally, Neutrogena uses GMS in its lotions to improve consistency and effectiveness. The growing demand for clean-label ingredients has led many brands to highlight GMS in their products, fuelling market growth.

Other elements to consider while establishing a glycerin monostearate plant include raw material sourcing, workforce planning, and packaging. The production of glycerol monostearate relies on glycerol and stearic acid, which are typically sourced from vegetable oils or animal fats. Glycerol is often derived as a byproduct from the biodiesel production process, while stearic acid can be obtained from palm oil and soy oil. These raw materials undergo a glycerolysis reaction, where they are combined to produce glycerol monostearate. These materials are essential for creating this emulsifying agent known as GMS.

Moreover, to help stakeholders determine the economics of a glycerin monostearate plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Glycerol monostearate (GMS), a glycerol ester of stearic acid, is widely used as an emulsifier and stabiliser in various industries, particularly food and cosmetics. It is a white, odourless powder that enhances the texture and shelf life of products, making it essential in baked goods, ice cream, margarine, and confectionery. GMS also finds applications in pharmaceuticals as a lubricant and coating agent for tablets and capsules. Its ability to create stable emulsions makes it valuable for both oil-in-water and water-in-oil systems. Glycerol monostearate has been in use since the early 20th century, with its first commercial production occurring in the 1920s. It gained prominence as a food additive in the mid-1900s when the FDA recognised it as Generally Recognized as Safe (GRAS) solid. Today, it is commonly used in gluten-free products and clean-label formulations, which highlight its adaptability to modern dietary trends.

Glycerol monostearate (GMS) is a white to cream-coloured, waxy solid with a slight fatty odour and taste. It has a melting point of 54-60°C and a boiling point of 290°C. GMS is characterised by its hydrophobic nature, making it insoluble in water (solubility of 0.1 g/100 mL at 25°C) but soluble in organic solvents like ethanol and chloroform. Chemically, GMS typically contains at least 90% monoglycerides, primarily glyceryl monostearate and glyceryl monopalmitate. It has an acid value of 5-10 mg KOH/g and an iodine value of 1-5 g I2/100 g, exhibiting emulsifying, thickening properties valuable in food, cosmetics, and pharmaceuticals. Additionally, GMS has a molecular weight of 358.57 g/mol and acts as a lubricant and release agent in industrial applications.

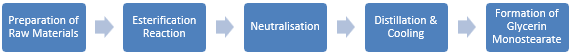

The production process of glycerol monostearate (GMS) begins with the preparation of raw materials, primarily glycerol and hydrogenated palm oil. These ingredients are mixed in an esterification reaction tank, where sodium hydroxide is added as a catalyst. The mixture is then heated to approximately 210°C under controlled pressure for about 30 minutes, resulting in the formation of crude glycerol monostearate. Following this, the crude product undergoes neutralisation by adding phosphoric acid to adjust the pH to around 6.0-7.5, after which it is stirred and allowed to stand for de-slagging. The thick ester is then subjected to multiple stages of distillation at varying temperatures (ranging from 160°C to 220°C) and vacuum pressures (from 5 pa to 150 pa) to remove impurities and separate glycerol from the monostearate. Finally, the high-quality glycerol monostearate is cooled and packaged for distribution.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

Glycerin monostearate (GMS) is primarily produced through the esterification or transesterification of glycerol with stearic acid or triglycerides containing stearic acid.

Process Description:

Raw Materials:

Glycerol (C3H8O3): A trihydroxy alcohol used as the base material.

Stearic Acid (C18H36O2): A saturated fatty acid derived from natural fats and oils.

Reaction Overview:

The production of glycerin monostearate involves esterification or transesterification. These are the primary methods:

Esterification Process:

This method reacts glycerol with stearic acid in the presence of a catalyst, typically an acidic catalyst like sulphuric acid or p-toluenesulfonic acid. The reaction yields glycerin monostearate and water.

Reaction: C3H8O3 + C18H36O2 → C21H42O4 + H2O

C3H8O3 (Glycerol) reacts with C18H36O2 (Stearic acid) to form C21H42O4 (Glycerin monostearate) and H2O (Water).

Transesterification Process:

Here, triglycerides containing stearic acid are reacted with glycerol. This method also requires a catalyst, typically an alkali like sodium hydroxide or potassium hydroxide.

Reaction: C57H104O6 (Tristearin) + C3H8O3 → 3C21H42O4

C57H104O6 (Tristearin) reacts with C3H8O3 (Glycerol) to form 3C21H42O4 (Glycerin monostearate).

Reaction Conditions:

Purification:

After the reaction, the crude product undergoes:

Glycerol monostearate (GMS) is widely used in the food industry because it enhances texture and shelf life in products such as baked goods, ice cream, and margarine. It also helps in preventing fat bloom in chocolates and improving creaminess in dairy products. The growing trend towards convenience foods and ready-to-eat snacks has driven demand for GMS in processed foods like sauces and dressings. Additionally, its applications extend to cosmetics, where it stabilises emulsions in creams and lotions, and pharmaceuticals, serving as a lubricant in tablet formulations. Government reports indicate that a rising focus on natural ingredients is further propelling the use of GMS as a clean-label alternative in food and personal care products. The increasing consumer awareness about health and wellness is also driving the market, as GMS aligns with the demand for healthier food options without compromising on quality or taste.

A detailed overview of production cost analysis that evaluates the manufacturing process of glycerin monostearate is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a glycerin monostearate production plant:

Market Dynamics and Trends: Factors such as expansion of the pharmaceutical industry are significantly affecting market conditions in the glycerin monostearate sector. In pharmaceuticals, GMS is valued for its emulsifying properties that enhance drug delivery systems and improve product stability. It can be found in formulations for products like protein shakes and various topical medications. Notable topical medications that use glycerol monostearate include Altoprev (lovastatin), Azulfidine EN-tabs (sulfasalazine), and Esomeprazole Magnesium Delayed-Release (for acid reflux). As these industries continue to grow, glycerol monostearate's role as an ingredient is propelling its market demand. Understanding these trends helps businesses align their production plans in the glycerin monostearate market.

Profiling of Key Industry Players: Leading companies in the glycerol monostearate market include BASF SE, Croda International PLC, DuPont, Clariant, Akzo Nobel N.V., and Evonik Industries AG. These manufacturers are known for their extensive product portfolios and strong distribution networks, which enable them to cater to a wide range of applications across industries such as food, pharmaceuticals, and cosmetics.

Recently, Croda International PLC announced the inauguration of a new production facility in Jurong Island, Singapore, aimed at meeting the growing demand for esters and alkoxylates. This investment reflects the company's commitment to expanding its production capacity to support the rising consumption of glycerol monostearate in various sectors. Additionally, in 2024, Oleon N.V. doubled the capacity of its isostearic acid and dimer acid production plant in Belgium, further indicating the competitive landscape and growth potential within the glycerol monostearate market.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in glycerol monostearate prices are influenced by several factors. One significant factor is the cost of raw materials, particularly glycerol and stearic acid, which are essential for its production. As of January 2025, the price of glycerol in North America is approximately USD 0.69 per kg, while in Europe, it is around USD 0.68 per kg. In Northeast Asia, the price is about USD 0.66 per kg, and in Southeast Asia, it has risen to USD 0.75 per kg. Meanwhile, price of stearic acid is generally influenced by the prices of palm oil and other vegetable oils, which have seen fluctuations due to market demand and supply chain dynamics. As of recent trends, stearic acid prices typically range from USD 1.50 to USD 2.50 per kg. Changes in the availability or pricing of these inputs can directly impact the overall cost of glycerol monostearate.

Additionally, as the food and cosmetic industries expand, demand for glycerol monostearate can also increase, potentially leading to price hikes. Supply chain dynamics also affect pricing as disruptions in production or transportation can lead to shortages, causing prices to rise. Furthermore, regulatory changes regarding food and cosmetic ingredients can influence market conditions, as manufacturers may need to adjust their formulations or sourcing strategies to comply with new standards. These factors collectively shape the pricing landscape for glycerol monostearate in the market.

Establishing a glycerin monostearate manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of a glycerol monostearate manufacturing facility must comply with various regulatory frameworks. It must adhere to food safety standards as an approved food additive, with specifications outlined in the Food Chemicals Codex (FCC). In the cosmetic industry, standards such as IS 4236 govern its use in formulations. Compliance with these regulations is essential for ensuring product safety, efficacy, and market acceptance. However, glycerol monostearate is identified as an approved pharmaceutical excipient and is listed in major pharmacopoeias, including the United States Pharmacopeia (USP) and the European Pharmacopoeia (Ph.Eur). It is also included in the US FDA Inactive Ingredients Database for various formulations, indicating its safety for pharmaceutical use.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the glycerin monostearate industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share