Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Furniture Polish Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a furniture polish plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for furniture polish is rising due to growth in home furnishings. This growth is particularly evident in residential construction, which accounts for approximately 36% of total spending, necessitating effective maintenance products like furniture polish to preserve the aesthetic appeal of these investments. Rising disposable incomes play a crucial role as well. In many emerging economies, disposable income levels are expected to rise significantly, allowing consumers to invest more in premium furnishings. As reported by various economic forecasts, by 2031, India's GDP per capita is projected to increase from approximately USD 2,268 to USD 5,140. This shift is expected to significantly boost the number of households earning above USD 5,000 annually, from 26% to 54%, enhancing consumer spending power.

Urban household disposable incomes are anticipated to continue their upward trend, with cities like Beijing projected to reach average disposable incomes of around USD 60,740 by 2040, nearly matching those of developed cities such as Tokyo and Barcelona. Countries like Indonesia and Thailand are also experiencing rapid growth in disposable incomes.

Other elements to consider while establishing a furniture polish plant include raw material sourcing, workforce planning, and packaging. The production of furniture polish relies on several key raw materials, such as nonionic and anionic surfactants, ethyl alcohol, and wax emulsions. These ingredients are essential for cleaning and polishing formulations. Other materials like carnauba wax and mineral oil are commonly used to enhance the polish's properties.

Moreover, to help stakeholders determine the economics of a furniture polish plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Furniture polish is a product designed to clean, protect, and enhance the appearance of wood surfaces. It typically contains oils, waxes, and solvents that nourish the wood, creating a protective barrier against moisture and dirt while imparting a glossy finish. The use of furniture polish dates back thousands of years, with beeswax being one of the earliest forms recorded in history. It was commonly used in ancient Egypt and throughout the Roman Empire. By the 18th century, techniques like French polishing gained popularity in Europe. Today, it is widely used to make furniture and other interiors.

Furniture polish appears as a liquid, often white or clear, with a characteristic odour. Its viscosity ranges from 1 to 40 centipoise (cps) at room temperature, allowing for easy application. The pH level generally falls between 5 and 8, with most formulations around 6 to 7.5, ensuring compatibility with wood finishes. Chemically, furniture polish commonly includes a hydrocarbon solvent ranging from 1% to 15%, silicone at 1% to 5%, and surfactants from 0.05% to 5%, which help emulsify the mixture and enhance cleaning. Additionally, some formulations may contain up to 10% natural oils, such as lemon or orange oil, which provide a pleasant fragrance and additional cleaning properties. It is soluble in water at concentrations of up to 20%, facilitating easy cleanup and application. The polish is stable under normal conditions, with a shelf life of about 2 to 3 years, and exhibits resistance to smearing and water staining, providing a long-lasting protective layer on furniture surfaces.

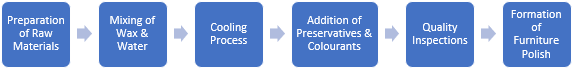

The production process for furniture polish begins with gathering all necessary raw materials, including 60% to 80% water, 5% to 15% wax (such as carnauba or beeswax), 1% to 5% emulsifiers (like glyceryl stearate), and 0.05% to 5% surfactants (such as sodium lauryl sulfate). Initially, the water phase is prepared by heating water to a temperature of 158-176°F (70-80°C). Emulsifiers and surfactants are then added to the heated water to facilitate mixing. Meanwhile, the wax phase is prepared by heating wax and oil ingredients, typically at temperatures around 160°F (70°C).

Once both phases are ready, the wax phase is slowly combined with the water phase while mixing until a homogeneous mixture is achieved. After cooling the mixture to room temperature, additional ingredients such as preservatives (up to 1%), colourants, and fragrances (around 0.1% to 2%) are incorporated. Quality control testing follows, assessing parameters like viscosity and pH. The finished product is then pumped to a filling line, where it is filled into containers or aerosol cans. Finally, containers are sealed, labelled, and packaged for distribution.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The process of making furniture polish involves the following steps:

Ingredients

1. Beeswax or Carnauba Wax (C15H30O2): Provides a protective layer and shine.

2. Mineral Oil (Hydrocarbons, typically C15-C20): Used as a base oil to prevent dryness and improve spreadability.

3. Solvents: Such as Turpentine (C10H16), used to thin wax and oil mixture for easy application.

4. Essential Oils: For scent and sometimes antimicrobial properties.

Process

1. Wax Preparation

Carnauba wax or beeswax is melted at around 85-90°C (185-194°F).

2. Oil and Solvent Addition

Mineral oil and turpentine are added in a specific ratio to create the desired consistency. This may vary depending on the brand and type of polish.

Chemical Reaction (for Carnauba Wax and Turpentine):

C15H30O2 + C10H16 → (No direct reaction, physical mixing)

3. Essential Oil Addition

Essential oils are added at lower temperatures to prevent degradation. Common oils include Lemon Oil (C10H16) for fragrance and antibacterial effects.

4. Emulsification and Stabilisation

To improve consistency, emulsifiers like Polysorbate 20 (C26H49O11) can be used if the polish is water-based.

5. Cooling and Packaging

The mixture is allowed to cool, forming a semi-solid paste, then packaged.

Primarily used in residential and commercial settings, furniture polish serves to clean, protect, and enhance the aesthetic appeal of wooden furnishings. The global middle-class population has increased by approximately 1.5 billion over the past decade, leading to higher disposable incomes and investments in home decor, with consumers spending an average of USD 1,500 annually on home maintenance products. Additionally, the hospitality industry is expanding rapidly, with over 700,000 hotels worldwide and a projected growth rate of 5% annually, driving the need for effective maintenance solutions for furniture in hotels and restaurants.

Government reports further indicate that urbanisation is accelerating, particularly in regions like South Asia and the Pacific, where urban populations are expected to rise by 1.3 billion by 2050, significantly increasing the demand for quality furniture care products. Furthermore, the shift towards eco-friendly products is notable; a survey revealed that 75% of consumers prefer low-VOC and non-toxic polishes due to heightened awareness of indoor air quality. Moreover, the market is expanding due to the rise of e-commerce platforms, which have seen a 20% increase in online sales of furniture care products over the past year.

A detailed overview of production cost analysis that evaluates the manufacturing process of furniture polish is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, in January 2025, Royaloak Furniture launched the Verona Italian Leather Recliner Set, which features premium Italian leather. This launch is likely to positively impact makers of furniture polish. As luxury furniture becomes more prevalent, the demand for effective maintenance products, such as furniture polish, will increase to preserve the quality of these high-end items.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a furniture polish production plant:

Market Dynamics and Trends: Factors such as environmental awareness are significantly affecting market conditions in the furniture polish sector. A growing demand for eco-friendly cleaning solutions is prompting manufacturers to innovate their product lines. Understanding these demands and trends helps businesses align their production plans in the furniture polish market.

Profiling of Key Industry Players: Leading manufacturers included in the furniture polish report are Reckitt Benckiser Group plc (Old English), S.C. Johnson & Son, Inc. (Pledge), The Sherwin-Williams Company, Liberon Limited, and Akzo Nobel N.V. These companies are known for their extensive product lines and innovations within the market.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in furniture polish prices are influenced by several key factors. The prices of essential ingredients, such as oils and solvents, can vary due to supply chain disruptions or changes in demand. The shift towards eco-friendly and sustainable products is driving manufacturers to innovate, which may lead to higher prices for premium formulations. An increase in construction activities and the growing middle-class population, particularly in emerging economies, boosts demand for furniture polish, further influencing pricing dynamics as manufacturers adjust to market needs and consumer trends.

Establishing a furniture polish manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the furniture polish industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share