Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Forged GI Pins Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a forged GI pins plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for forged GI pins is increasing due to growth of the automotive industry. As per industry reports, global vehicle production reached approximately 94.7 million units in 2024, representing a 3.3% increase from 2023. Major producers include China, projected to produce around 27 million vehicles, the United States at approximately 15.9 million, and Germany at about 5 million units. This growth translates into a heightened need for reliable forged components like GI pins, which are crucial for applications in suspension systems and engine mounts. Secondly, the expansion of infrastructure projects worldwide is contributing to demand as forged GI pins. Notable examples include the California High-Speed Rail, which aims to connect major cities across California and has an estimated cost of USD 80 billion. Similarly, the Cross rail project in London, costing around EUR 18 billion, will improve transportation across the city and surrounding areas. In India, the government has announced investments of over INR 1.4 trillion for infrastructure development by 2025, including over 100 smart cities and extensive highway upgrades. These projects will require forged GI pines in structural applications and heavy machinery, leading to market demand.

Other elements to consider while establishing a forged GI pins plant include raw material sourcing, workforce planning, and packaging. The production of forged GI pins relies on several key raw materials, such as galvanised iron (GI), which is sourced from steel manufacturers that produce high-quality iron billets. These billets are typically cut to specific dimensions, around 50 mm in diameter and 200 mm in length, before undergoing the forging process. The galvanised coating is applied to enhance corrosion resistance. Additionally, zinc is used in the galvanisation process, sourced from mining operations that extract high-purity zinc ore. These materials are necessary to produce durable GI pins.

Moreover, to help stakeholders determine the economics of a forged GI pins plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Forged GI pins are fasteners made from galvanised iron (GI) that are commonly used in construction and engineering applications. These pins are known for their strength, durability, and resistance to corrosion, making them ideal for securing structural components. The forging process enhances the mechanical properties of the metal, resulting in a product that can withstand significant stress and strain. The use of forged metal fasteners dates to ancient civilisations, where blacksmiths created tools and structural components through manual forging techniques. With the industrial revolution in the 18th century, advancements in metallurgy and mass production led to the widespread adoption of forged components in construction. Today, forged GI pins are used in applications ranging from scaffolding to heavy machinery assembly.

Forged GI pins exhibit high tensile strength, typically exceeding 5 kN for 11 kV applications and 10 kN for 33 kV applications, ensuring they can endure significant loads without failure. The forging process enhances their durability and toughness, allowing them to withstand mechanical stress in demanding environments. Additionally, the hot-dip galvanisation provides a protective zinc coating that effectively prevents corrosion. Forged GI pins not only offers inherent resistance to rust but also ensures a long-lasting protective layer due to the excellent adhesion of the zinc coating. This material is generally non-toxic, making it safe for use in electrical installations and construction projects.

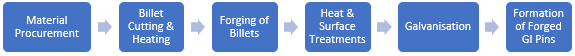

The production process of forged GI pins begins with raw material procurement, where high-quality galvanised iron billets are sourced. The iron is then cut into billets of specific dimensions, typically around 50 mm in diameter and 200 mm in length, during the billet shearing/cutting stage. These billets are heated in temperature-controlled induction heaters to approximately 1,200°C. In the forging process, the heated billets are shaped using drop hammers or screw presses, achieving a tensile strength exceeding 5 kN for 11 kV applications and 10 kN for 33 kV applications. After forging, the pins undergo heat and surface treatment, where the forged pins are hot dip galvanised according to standards such as IS: 2629. Rigorous quality control inspection follows, where each batch is tested for dimensional accuracy and mechanical integrity. Finally, the pins are carefully packaged and shipped to customers.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The forged GI pins market is driven by several applications in the electrical and construction industries. These pins are primarily used for securing insulators in overhead power lines, with specifications indicating that 11 kV pins must withstand a minimum failing load of 5 kN, while 33 kV pins must handle at least 10 kN, as outlined by the West Bengal State Electricity Distribution Company. The market is also growing due to the increasing demand for robust fastening solutions in infrastructure projects and renewable energy initiatives. For instance, India aims to achieve 500 GW of installed renewable energy capacity by 2030, with current figures showing over 209.63 GW already in place, including a substantial increase in solar capacity from 2.6 GW to 90.76 GW since 2014.

This growth is supported by government investments, such as the allocation of INR 10,000 crore for the Centrally Sponsored Scheme for Solar Power in the Union Budget 2024-25, marking a 110% increase from the previous year. Additionally, the National Green Hydrogen Mission targets the production of 5 million tons of green hydrogen by 2030, further necessitating the demand for forged GI pins in infrastructure. The government is also enhancing power transmission infrastructure through initiatives like the Green Energy Corridor, which supports the evacuation of renewable energy. This development is increasing the demand for high-quality forged GI pins that can endure the mechanical stresses involved in these applications.

A detailed overview of production cost analysis that evaluates the manufacturing process of forged GI pins is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a forged GI pins production plant:

Market Dynamics and Trends: Factors such as the rising number of air passengers worldwide are significantly influencing market conditions in the forged GI pins sector. The aerospace industry is experiencing increased demand for high-strength forged components due to a surge in air travel. The International Air Transport Association (IATA) recently reported that global air passenger numbers are projected to reach 4.5 billion by 2025, indicating a robust recovery and growth in the sector.

Additionally, the trend towards renewable energy investments is driving demand for durable fastening solutions in equipment installations. Global investments in renewable energy reached approximately USD 500 billion in 2023, with significant projects like the Hornsea One offshore wind farm in the UK, which boasts a capacity of 1.2 GW. Understanding these demands and trends allows businesses to align their production strategies effectively within the forged GI pins market, ensuring they meet the evolving needs of both the aerospace and renewable energy sectors.

Profiling of Key Industry Players: Leading manufacturers included in the forged GI pins report are Bharat Forge, a prominent forging company in India known for its advanced manufacturing capabilities, and Sanjay Casting & Engineering Company, recognised for its specialised production of fasteners. Shree Krishna Forge Expo (P) Ltd. is also highlighted for its focus on high-quality forged components. Recently, these manufacturers have been expanding their production capacities to meet the rising demand in infrastructure projects and renewable energy goals, such as Australia's aim to add approximately 5400 MW of wind capacity and 3600 MW of rooftop solar capacity annually between 2026 and 2030. This strategic expansion aligns with the increasing need for durable fastening solutions in construction and electrical installations.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in forged GI pins prices are influenced by several key factors. The cost of raw materials, particularly galvanised iron and zinc can vary due to market demand and supply chain disruptions. Economic conditions and trade policies, such as tariffs on steel imports, also impact production costs. Additionally, rising demand from industries like construction and automotive, driven by major infrastructure projects, contributes to price volatility. Lastly, inflation rates and changes in labour costs further affect pricing dynamics in the forged GI pins market.

Establishing a forged GI pins manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the forged GI pins industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share