Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Floating Shelf Unit Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a floating shelf unit plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

| Floating Shelf Unit Product Details: | |

| Product Name | Floating Shelf Unit |

| Appearance and Color | Rectangular shelf, various finishes (e.g., black, white, walnut, oak) |

| Common Names | Wall Shelf, Invisible Shelf, Wall-Mounted Shelf |

| Top Exporting Countries | USA, United Kingdom, China, Vietnam, Germany |

The demand for floating shelf units is increasingly driven by urbanisation, particularly as living spaces shrink in densely populated areas. According to projections, India's urban population has raised from 31.1% in 2011 to approximately 35-37% in 2024. Additionally, the number of cities with populations exceeding one million is projected to grow from 52 in the 2011 Census to around 75-80 by 2024, highlighting the challenges of accommodating larger populations within limited urban spaces. The United Nations estimates that as of 2024, approximately 57.25% of the world's population lives in urban areas, a figure expected to rise to 68% by 2050, adding about 2.5 billion people to urban areas globally, predominantly in Asia and Africa. These figures demonstrate the need for efficient space solutions like floating shelves that cater to the needs of modern city dwellers.

Other elements to consider while establishing a floating shelf unit plant include raw material sourcing, workforce planning, and packaging. Wood is the primary material used, with options ranging from solid woods like oak, maple, and pine to engineered woods such as plywood and MDF (medium-density fiberboard). Metal components are often used in the brackets and supports that hold the floating shelves in place. High-quality adhesives are used to securely assemble floating shelves. Finishing materials such as stains, paints, or sealants are applied to enhance the appearance and protect the wood from moisture and wear. Finally, various fasteners, including screws and anchors, are required for securely mounting the shelves to walls. These raw materials contribute to the functionality and design of floating shelf units.

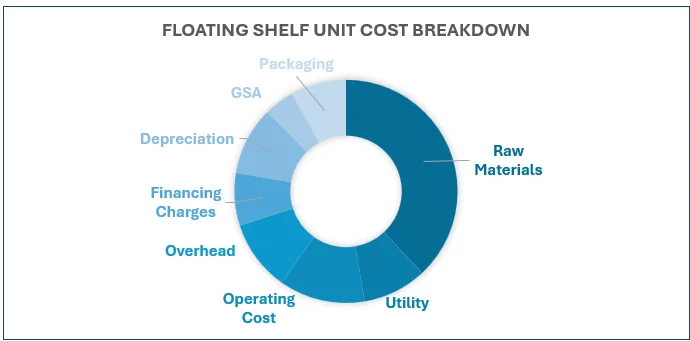

Moreover, to help stakeholders determine the economics of a floating shelf unit plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Read more about this report - Request a Free Sample

A floating shelf is a shelf with hidden wall fixings, giving it a sleek, minimalist appearance without visible supporting brackets. This design, attributed to contemporary designer Magnus McCormick in the late 1950s, has become a timeless furniture icon, seamlessly integrating into modern interiors. Floating shelves expand storage options and serves as overhead storage, console tables, or even radiator tops. However, they have limitations; they are generally unsuitable for heavy loads due to the torque created from shelf loading compared to the holding power of screws against the wall.

The key physical property of floating shelf units is the concealed wall fixings that create the illusion of shelves "floating" on the wall, providing a sleek, minimalist look. These shelves are available in various materials, including wood, glass, metal, and acrylic, allowing homeowners to choose a style that complements their existing decor. Solid wood shelves are durable and offer a traditional aesthetic, while metal and glass provide a contemporary look. Typically, at least 1.25" thick, floating shelves are designed to support up to 50 lbs per stud with proper installation. In terms of chemical properties, wood shelves are susceptible to moisture and can warp or crack if not properly sealed, while metal shelves are corrosion-resistant and easy to clean and glass and acrylic shelves are non-porous and require minimal maintenance.

The production process of a floating shelf unit begins with identifying customer demand and creating design specifications, followed by the procurement of raw materials such as wood and brackets. Once materials are acquired, they undergo inspection for quality before being prepared through cutting and sanding. The assembly phase involves putting together the shelf structure and attaching necessary components, which is then followed by a quality control check to ensure structural integrity. After assembly, the shelves receive finishing touches, such as stains or paints, and undergo a final inspection to confirm compliance with standards. Once approved, the finished units are packaged for shipment.

Read more about this report - Request a Free Sample

Below is the detailed process of making a floating shelf unit:

1. Raw Materials

The primary materials used in the production of floating shelf units include:

2. Wood Preparation and Treatment

Wood used for floating shelves often undergoes treatment to protect it from moisture, insects, and decay. Chemical treatments include the application of preservatives such as copper-based compounds (copper azole) or borates. The chemical reactions in wood preservation typically involve the binding of these chemicals to cellulose fibers in the wood.

Wood Preservation

One common chemical used in wood preservation is copper azole, which reacts with the wood to protect it from decay:

Copper(II) oxide (CuO) + Azole → Copper azole complex

3. Adhesives

Adhesives such as polyvinyl acetate (PVA) wood glue are used in the assembly of floating shelves, particularly for joining wood components. PVA adhesives form strong bonds as the water in the emulsion evaporates, leaving behind the polymer that adheres to the wood fibers.

Polyvinyl acetate is synthesised through the polymerisation of vinyl acetate monomers:

nCH2=CH(OCOCH3) → (CH2-CH(OCOCH3))n

4. Metal Bracket Production

The metal brackets used to support floating shelves are typically made from steel or aluminum. The metal is shaped and welded to create the bracket. If steel is used, it may undergo galvanisation, where it is coated with zinc (Zn) to prevent rust. The reaction in galvanisation is as follows:

Zn + Fe → ZnFe (zinc-iron alloy)

5. Finishing

The finishing process involves the application of paints, varnishes, or lacquers to the surface of the wood. These finishes protect the wood and improve its aesthetic appeal. Most paints and varnishes contain organic solvents that evaporate during the drying process, leaving behind a solid protective layer.

For example, polyurethane varnish involves the following curing reaction as it dries and hardens:

R-N=C=O (isocyanate) + R-OH (polyol) → Polyurethane

The floating shelf unit market is driven by several applications, primarily in the household, hospitality, and retail sectors. The increasing demand for space-efficient storage solutions in urban settings is a significant driver, as homeowners and businesses seek to optimise limited space while enhancing aesthetic appeal. For example, floating shelves are popular in modern home decor for displaying books, plants, and decorative items, while hotels use them to create stylish and functional guest rooms. Additionally, the rise of DIY home improvement projects has further fuelled market growth, as consumers look for accessible and customisable shelving options. Innovations in materials and manufacturing processes, such as the use of sustainable wood and advanced cutting technologies, also contribute to the market's expansion, aligning with the growing demand for eco-friendly interior.

A detailed overview of production cost analysis that evaluates the manufacturing process of floating shelf unit is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, India witnessed sale of 25,000 luxury homes in 2023, which is a 30% increase from 2022.

This growth is attributed to rising disposable incomes, which have increased by around 10% over the past year, and a shift in consumer preferences towards premium living spaces. Notably, 85% of luxury home buyers are looking for properties priced above INR 1 crore (approximately USD 120,000) and many are seeking homes in the range of INR 2-5 crore. The surge is likely to positively impact makers of floating shelf units as residents are investing in stylish and functional decor, including floating shelves, which offer both aesthetic appeal and space-saving solutions.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a floating shelf unit production plant:

Market Dynamics and Trends: The growing popularity of DIY (Do It Yourself) home improvement projects have significantly affected market conditions in floating shelf unit sector. According to surveys, around 70% of homeowners reported engaging in DIY projects in the past year as they are seeking innovative ways to personalise their living spaces affordably and creatively. In such cases, floating shelves offer a versatile solution that is not only easy to install but also customisable to fit various styles and preferences. Understanding these factors helps businesses align their production plans with demands and trends in the floating shelf unit market.

Profiling of Key Industry Players: Leading manufacturers like IKEA, Wayfair, and Rakks Shelving Systems are included in the floating shelf unit report. Other notable players are Roj Exim Pvt. Ltd., Global Marketing Empire, and Deodap International Private Limited. These companies offer a diverse range of products to maintain their market presence.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in floating shelf unit prices are influenced by several key factors, particularly the costs of essential raw materials such as wood, metal, and adhesives. The type of wood used can significantly affect pricing; for instance, solid hardwoods like oak or maple tend to be more expensive than engineered woods such as MDF or plywood. Additionally, the cost of metal components can vary based on market demand and availability.

The design complexity of the shelves also influences pricing as customised designs typically incur higher costs compared to standard, ready-made options. As manufacturers navigate these variables, they must also consider broader economic conditions, including supply chain disruptions or changes in consumer demand, which can further influence the pricing dynamics of floating shelf units.

Establishing a floating shelf unit manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

Read more about this report - Request a Free Sample

| Report Features | Coverage - Detailed Report |

| Product Name | Floating Shelf Unit |

| Report Coverage | Manufacturing Process & Unit Operations: In-depth analysis of each step involved in the production from raw materials, including technical tests, mass balance, and key unit operations. |

| Plant Infrastructure & Development: Comprehensive review of land selection, site development, environmental impacts, construction costs, and project phasing. | |

| Plant Layout & Design: Factors influencing the plant layout, including space planning, machinery placement, and operational efficiency. | |

| Machinery & Equipment Requirements: Analysis of machinery needs for production, including costs, suppliers, and technological advancements. | |

| Raw Material Procurement & Costs: Detailed breakdown of raw material requirements, procurement strategies, supplier options, and cost structures. | |

| Packaging & Distribution: Insight into packaging requirements, material selection, procurement channels, and associated costs. | |

| Operational Costs & Resources: Examination of utility needs (water, electricity), transportation logistics, human resources, and other operational costs. | |

| Financial & Economic Analysis: Project investment costs, financial projections, income/expenditure forecasts, and cost-benefit analysis. | |

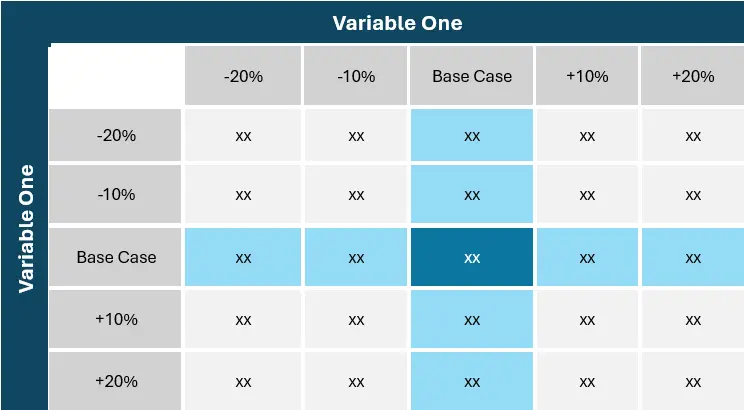

| Profitability & Risk Analysis: Financial performance metrics, including profitability margins, payback period, and sensitivity to market risks. | |

| Market & Competitive Landscape: Competitive positioning, market trends, regional breakdown, and strategic recommendations for market growth. | |

| Currency | USD (Data can also be provided in the local currency) |

| Customization Scope | The report can also be customised based on the requirements of the customer |

| Post-Sale Analyst Support | 10-12 weeks of post-sale analyst support available. |

| Data Access | Lifetime Access |

| Delivery Format | PDF and Excel through email (We can also provide the editable version of the report in PPT/Word format on special request) |

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the floating shelf unit industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share