Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Electric Lawn Aerator Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing an electric lawn aerator plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for electric lawn aerators is increasing due to the rising popularity of lawn care among homeowners and businesses. Globally, there are an estimated 40 million acres of land dedicated to lawns in the United States alone, reflecting a significant investment in maintaining healthy and aesthetically pleasing outdoor spaces. This trend is evident in the growing interest in gardening and outdoor aesthetics, prompting consumers to seek equipment like electric aerators that can promote healthy grass growth and improve overall lawn health. Additionally, technological advancements have made electric lawn aerators more efficient and user-friendly. Innovations such as battery-powered models and self-propelled designs reduce manual labour and enhance ease of use, appealing to both homeowners and professional landscapers. Electric aerators also contribute to soil health by reducing the need for chemical fertilisers while improving water retention. As more people recognize the importance of well-maintained lawns, estimated to cover over 128,000 square kilometers in the U.S., the demand for efficient tools like electric aerators is expected to rise.

Other elements to consider while establishing an electric lawn aerator plant include raw material sourcing, workforce planning, and packaging. The production of electric lawn aerators relies on several key raw materials, such as high-strength steel for tines, polypropylene for the housing, and various electrical components for the motor. High-strength steel is essential for the durability and effectiveness of the aerator's tines, while polypropylene is used to create a lightweight yet robust housing that can withstand outdoor conditions. Electrical components, including motors with power ratings typically ranging from 1,200W to 1,600W, are crucial for the aerator's performance. These raw materials are typically sourced from various industrial suppliers and manufacturers dealing in metal and plastic production. By leveraging reliable supply chains for these essential materials, manufacturers can provide high-quality electric lawn aerators in the market.

Moreover, to help stakeholders determine the economics of an electric lawn aerator plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

The electric lawn aerator is a crucial tool for maintaining healthy lawns by improving soil aeration and promoting root growth. It works by creating small holes in the soil, allowing air, water, and nutrients to penetrate deeper. The evolution of aerators has significantly enhanced their efficiency as early models were often heavy and cumbersome, making the task labor-intensive. In the 1980s, manufacturers began developing lighter, more effective walk-behind aerators. The concept of lawn aeration gained traction in the mid-20th century as lawn care became more popular. In 1972, Union Carbide expanded aeration technology in the U.S. to improve water quality in lakes. By the late 1980s, significant advancements led to the development of user-friendly aerators that transformed lawn care practices. Today, advanced models feature multifunctional capabilities, such as integrated seeders, making aeration a quicker and more productive process.

Electric lawn aerators possess several important properties. Physical properties include power ratings typically ranging from 1,200W to 1,600W, allowing them to effectively remove thatch and aerate the soil. They often feature adjustable working depths, with settings ranging from -12 mm to +6 mm, enabling users to customise the aeration process based on lawn conditions. The width of the aeration path usually varies between 30 cm to 40 cm. The materials used in construction include durable plastics and metals; for example, the deck is often made from anti-rust polypropylene or aluminum, ensuring longevity. Additionally, electric lawn aerators are designed to reduce environmental impact by eliminating emissions associated with gas-powered models, making them an eco-friendlier option for lawn care. Many models also feature noise levels around 60-70 dB, providing a quieter operation compared to traditional gas-powered alternatives.

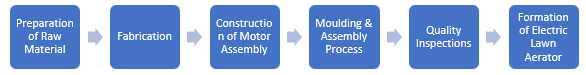

The production of electric lawn aerators begins with the procurement of raw materials such as high-strength steel for tines, polypropylene for the housing, and various electrical components for the motor. The process starts with the fabrication of tines, which are shaped and treated to resist corrosion. Next, the motor assembly is constructed, typically featuring a power rating between 1,200W and 1,600W, which provides sufficient power for effective aeration. The housing is moulded from polypropylene, which is designed to withstand outdoor conditions. Once all components are prepared, they are assembled. Next, each unit undergoes rigorous quality testing before being packaged for distribution.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The growing popularity of residential gardening is a significant factor driving electric lawn aerator market growth. Government reports indicate that home gardening has surged by over 30% since 2020, leading to a rise in gardening-related expenditures, which reached approximately USD 47 billion in the U.S. in 2023. This trend has resulted in a growing demand for efficient lawn care tools, including electric aerators, which help improve soil health and promote robust grass growth.

Additionally, the shift towards sustainable landscaping practices is propelling market growth; homeowners are increasingly aware of the benefits of aeration in reducing soil compaction and enhancing water absorption. For example, initiatives such as the U.S. Department of Agriculture's Urban Agriculture initiative support community gardens and urban landscaping projects, which have seen funding increases of about 20% in recent years. Also, advancements in technology have led to the development of user-friendly electric aerators, further leading to market growth.

A detailed overview of production cost analysis that evaluates the manufacturing process of electric lawn aerator is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, in January 2025, Graze Robotics launched the production of its next-generation autonomous mower, designed to enhance efficiency in lawn maintenance. The mower features a 60-inch tri-blade deck, capable of mowing 1.6 acres per hour with an 8-hour runtime, making it suitable for large commercial landscapes such as airports and solar fields. Equipped with advanced sensors and a 360-degree safety system, it ensures obstacle detection and avoidance while providing real-time monitoring through a dedicated app. Other manufacturers can also leverage these technological advances and product innovations to capture a growing market share.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for an electric lawn aerator production plant:

Market Dynamics and Trends: Factors such as the growing popularity of residential gardening, rising number of urban landscaping projects, and the shift towards sustainable landscaping practices are significantly affecting market conditions in the electric lawn aerator sector. The U.S. Department of Agriculture's Urban Agriculture initiative has seen funding increases of about 20%, supporting community gardens and urban landscaping projects that emphasize the importance of aeration in reducing soil compaction and enhancing water absorption. As homeowners and commercial landscapers become more aware of these benefits, the demand for electric lawn aerators continues to rise. Understanding these demands and trends helps businesses align their production plans in the electric lawn aerator market.

Profiling of Key Industry Players: Leading manufacturers in the electric lawn aerator market include John Deere, Toro, Billy Goat, Turfco, and Eco-Lawn. These brands hold significant market shares due to their strong reputation in the lawn care industry and their commitment to innovation. Recently, John Deere announced the upcoming launch of its autonomous robot lawnmower, designed for commercial landscaping, which features a powerful 21.4 kWh battery enabling up to 10 hours of operation. The mower uses four pairs of stereo cameras for 360-degree vision and dual GPS antennas for precise navigation, allowing it to operate even in areas without GPS coverage.

This innovative machine aims to address labour shortages in the landscaping industry, where maintaining qualified staff has become increasingly challenging, as highlighted by a report indicating a 50% labor shortage in professional and business services as of January 2024. Expected to hit the market by 2026, John Deere's autonomous mower reflects a growing trend towards automation in lawn care. Such moves position these manufacturers at the forefront of the evolving market.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in electric lawn aerator prices are influenced by raw material costs. The price of high-strength steel and polypropylene used in manufacturing can vary due to market demand and supply chain disruptions. In 2024, the cost of steel saw an increase of approximately 15%, impacting the overall production costs for manufacturers. Seasonal demand also affects pricing, as the spring and summer months typically see a surge in lawn care activities. For example, rental rates for aerators can range from USD 55 to USD 75 for a four-hour window, reflecting increased demand during peak gardening seasons. Moreover, advancements in features in electric aerators can lead to price variations; models with enhanced capabilities may command higher prices. Lastly, competition among manufacturers and the availability of rental options also contribute to price fluctuations, as homeowners may choose to rent rather than purchase equipment outright, further influencing market dynamics.

Establishing an electric lawn aerator manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the electric lawn aerator industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share