Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Drinking Chocolate Mix Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a drinking chocolate mix plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for drinking chocolate mix is increasing due to rising popularity of chocolate-based beverages in colder seasons when consumers seek comforting beverages. Industry surveys indicate that 66% of UK consumers enjoy hot chocolate or cocoa at least once a month, with 27% indulging weekly. This consistent consumption reflects a cultural affinity for hot chocolate as a comforting drink, driving demand for various chocolate mixes.

Increasing awareness of the health benefits associated with cocoa is another factor propelling market growth. Research has shown that dark chocolate can help lower cardiovascular disease risks and enhance blood flow due to its flavonoid content. As consumers become more health-conscious, they are turning to drinking dark chocolate mixes that offer these benefits, particularly those with reduced sugar content. Approximately 50% of UK consumers express interest in lower-sugar hot chocolate options, indicating a shift towards healthier alternatives.

Other elements to consider while establishing a drinking chocolate mix plant include raw material sourcing, workforce planning, and packaging. The production of drinking chocolate mix relies on several key raw materials, such as cocoa powder, which provides the essential chocolate flavour. Sugar is commonly used to sweeten the mix, while milk powder or creamer is often included to enhance creaminess and texture. Other ingredients may include vanilla extract for flavour or emulsifiers to improve consistency and shelf life. Some mixes also incorporate alternative sweeteners like jaggery or dates.

Moreover, to help stakeholders determine the economics of a drinking chocolate mix plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Drinking chocolate mix, often enjoyed as a comforting beverage, has evolved significantly over centuries. Originally consumed by the Mayans around 500 BC, it used to be a cold, spicy drink made from ground cocoa seeds, water, and various spices. The drink later made its way to Europe in the 1500s, where it was sweetened and served hot, gaining popularity among the elite. By the 18th century, innovations like mixing chocolate with milk led to the development of rich hot chocolate, now available in convenient mixes and various flavours worldwide. In 2024, spicy flavours like chili and seasonal favorites such as pumpkin spice are trending, alongside unique combinations like salted caramel and lavender. The market is also seeing a rise in low-sugar and plant-based hot chocolates, appealing to health-conscious consumers.

Drinking chocolate mix typically has a fine, powdery texture, allowing it to dissolve easily in hot liquids. The cocoa butter content gives it a melting point around 33-35°C (91-95°F), affecting how it behaves when heated. In terms of colour, drinking chocolate mix ranges from dark brown to light brown, depending on the cocoa content and processing methods used. Chemically, it is composed of cocoa solids, cocoa butter, sugar, and sometimes milk solids, which contribute to its taste and nutritional profile. Additionally, it is rich in polyphenols and flavanols, providing health benefits such as anti-inflammatory effects. The presence of alkaloids like theobromine and caffeine can also enhance mood and energy levels.

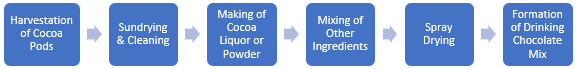

The production process of drinking chocolate mix begins with harvesting cocoa pods from cocoa trees, typically done by hand. The harvested pods are then fermented for about 7 days, a crucial step that develops the beans' flavour. After fermentation, the beans are sun-dried for approximately 10 days to reduce moisture content. Once dried, the beans undergo cleaning and grading to ensure quality before being shipped to manufacturers.

The next step is roasting, where the beans are roasted at controlled temperatures. Following roasting, the beans are subjected to winnowing, which removes the outer shells and yields cocoa nibs. These nibs are then ground into cocoa liquor, which can be separated into cocoa powder and cocoa butter. In the subsequent phase, the cocoa powder is mixed with sugar, milk solids, and other flavourings to create the chocolate mix. This mixture is then homogenised to achieve a uniform consistency. If an instant product is desired, the liquid mixture may be subjected to spray drying, transforming it into a fine powder. Finally, the finished drinking chocolate mix is packaged for distribution.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

One significant application of drinking chocolate mix is in health drinks, where chocolate mixes are increasingly used to create nutritious beverages. For instance, brands like Cacao Barry offer dark chocolate powders enriched with antioxidants, specifically targeting consumers interested in the health benefits of cocoa. Additionally, the growing popularity of flavoured milk and energy drinks has spurred market growth. Products like Nestlé’s Nesquik and Ovaltine have successfully captured this demographic by offering ready-to-mix chocolate drinks that are both delicious and easy to prepare.

Moreover, global chocolate consumption was approximately 8.13 million tons in 2022, with an estimated per capita consumption of about 1 kg per year. This has also provided an impetus to market expansion. The United States stands out as a major consumer, with Americans consuming about 9 kg of chocolate per person annually, while the Swiss lead globally with an impressive 11.8 kg per capita. Furthermore, the Indian government’s initiatives to promote dairy consumption have led to increased interest in chocolate milk products among children. Furthermore, online platforms like Amazon and Walmart have expanded their offerings of gourmet and speciality chocolate mixes, including organic options from brands like Equal Exchange and Coco & Eve, making it easier for consumers to explore new flavours.

A detailed overview of production cost analysis that evaluates the manufacturing process of drinking chocolate mix is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, cocoa production in 2024 is facing significant challenges, particularly in West Africa, where leading producers like Ghana and Côte d’Ivoire have reported declining yields due to pests, diseases, and climate change impacts. Ghana's output fell to just over 429,000 metric tonnes, less than 55% of its average. This decline has led to soaring cocoa prices, which reached around USD 10,000 per metric ton by mid-2024. As cocoa prices soar due to shortages, manufacturers may face increased production costs, leading to higher retail prices for consumers. Despite these difficulties, there is cautious optimism for the 2024/25 season, with Ghana's cocoa board projecting a recovery to approximately 650,000 tons.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a drinking chocolate mix production plant:

Market Dynamics and Trends: Factors such as rising demand for convenience products are significantly affecting market conditions in the drinking chocolate mix sector. The fast-paced lifestyle of modern consumers has led to a growing demand for convenience food products, including instant drinking chocolate mixes. These products allow consumers to consume chocolate beverage quickly and easily. The rise of e-commerce has further facilitated access to these products, making it easier for consumers to purchase their mixes online. Understanding these factors helps businesses align their production plans with demands and trends in the drinking chocolate mix market.

Profiling of Key Industry Players: Leading manufacturers like Nitin's Premixes, Hershey’s, Ghirardelli, Cadbury, and Tiggle are included in the drinking chocolate mix report. Recently, Nitin's Premixes has gained recognition for its high-quality hot chocolate and drinking chocolate mixes, which are made with premium cocoa and are used in cafes and restaurants. Hershey’s continues to be a household name, offering a familiar hot chocolate mix that is easy to prepare and enjoyed by consumers across various demographics. Ghirardelli, known for its rich chocolate products, has also expanded its offerings to include premium hot cocoa mixes that appeal to chocolate enthusiasts. Tiggle has also emerged as a favourite among families, particularly for its additive-free ingredient list and appealing taste that caters to children. These manufacturers are responding to the growing demand for delicious and convenient drinking chocolate options in the market.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in drinking chocolate mix prices are influenced by several key factors, particularly the rising costs of cocoa and other raw materials. In 2024, cocoa prices surged to nearly USD 9,500 per metric ton, marking a 47% increase over three months and more than double the price from a year ago. As manufacturers face these escalating costs, they are likely to pass them on to consumers, with estimates suggesting retail chocolate prices could rise by 30% or more in 2025. General inflation and higher costs for sugar and packaging contribute to these price increases, impacting overall consumer spending on chocolate products.

Establishing a drinking chocolate mix manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the drinking chocolate mix industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share