Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Dimethylglyoxime Manufacturing Plant Project Report 2025 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a dimethylglyoxime plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for dimethylglyoxime (DMG) is experiencing a significant increase due to its versatile applications in analytical chemistry. DMG is widely used as a reagent for detecting and quantifying metal ions, especially nickel and palladium. In the metal finishing industry, DMG is employed to detect the presence of nickel in electroplating solutions, where it forms a distinctive red precipitate. This application is crucial for ensuring product quality and compliance with safety standards, especially in consumer goods like jewelry, where nickel exposure can cause allergic reactions.

Another driving factor behind the growing demand for DMG is heightened regulatory scrutiny concerning health and environmental safety. Regulations such as the CEN/TR 12471:2022, which outlines screening methods for nickel in consumer products, highlight the need for reliable testing methods to prevent nickel exposure that can lead to dermatitis. Additionally, standards like IS 228-5 (1987) in India specify methods for determining nickel content using DMG in ferrous metals, reinforcing its importance in industries that must comply with strict safety regulations. As awareness of the potential health risks associated with metals increases, industries are compelled to adopt rigorous testing methods, further propelling the use of DMG as a reliable testing agent.

Moreover, advancements in analytical techniques are contributing to the rising demand for dimethylglyoxime. Innovations in chemical analysis, such as improved spectroscopic methods that use DMG for metal detection, help in improving accuracy and efficiency of testing processes. In emerging economies, industrial growth across sectors like pharmaceuticals and agriculture has led to increased usage of chemical reagents, including DMG. For instance, in agricultural soil testing, DMG can be used to detect trace metals that may affect crop health and safety. These factors position DMG as an essential compound for both research and industrial applications.

Other elements to consider while establishing a dimethylglyoxime plant include raw material sourcing, workforce planning, and packaging. The production of dimethylglyoxime (DMG) relies on several key raw materials, including acetaldehyde, Grignard reagent, methyl propanoate, hydroxylamine, and formaldehyde. Acetaldehyde and formaldehyde are commonly produced from the oxidation of ethanol or through the dehydrogenation of ethanol, while Grignard reagents are made from alkyl halides and magnesium. Hydroxylamine can be derived from ammonia and nitrous oxide or through other synthetic pathways involving hydroxylamine hydrochloride. The availability and pricing of these raw materials can significantly impact the overall production cost of dimethylglyoxime, making it crucial for manufacturers to maintain stable supply chains and relationships with reliable suppliers.

Moreover, to help stakeholders determine the economics of a dimethylglyoxime plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Dimethylglyoxime (C4H8N2O2) is a colourless, crystalline compound primarily used as a reagent in analytical chemistry, particularly for detecting nickel and palladium ions. It forms a distinctive red precipitate with nickel ions, making it valuable for qualitative and quantitative analysis in various samples. Additionally, dimethylglyoxime acts as a bidentate ligand, forming stable complexes with metals, which are of interest in coordination chemistry. Historically, dimethylglyoxime was first produced in 1905 by Russian chemist Lev Chugaev, who discovered its nickel-complexing properties. It has since become one of the earliest organic reagents used in analytical chemistry, however, the applications now include roles in metal ion detection and environmental analysis.

Dimethylglyoxime (C4H8N2O2) is a white crystalline compound having a density of 1.37 g/cm³ and a molecular weight of 116.12 g/mol. The melting point ranges from 240 to 241 °C, while its boiling point is approximately 300 °C, though it decomposes before reaching this temperature. Dimethylglyoxime is insoluble in water (solubility < 1 g/100 mL) but soluble in alcohol (about 10 g/100 mL in ethanol) and sodium hydroxide solutions. It is odourless and exhibits two hydrogen bond donors. Chemically, it acts as a bidentate ligand, forming stable complexes with metal ions, particularly nickel, resulting in an insoluble red precipitate when reacted with nickel ions at concentrations as low as 0.1 mm.

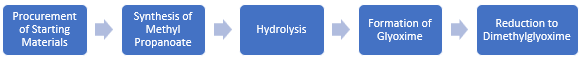

The production of dimethylglyoxime (C4H8N2O2) begins with starting materials such as acetaldehyde (C2H4O) and methylmagnesium bromide (CH3MgBr). In the first step, acetaldehyde reacts with the Grignard reagent to form methyl propanoate (C4H8O). This intermediate undergoes hydrolysis in the presence of water to yield hydroxylamine (C2H7NO). Next, hydroxylamine reacts with formaldehyde (CH2O) to form glyoxime (C4H8N2O), which is then reduced using lithium aluminium hydride (LiAlH4) to produce the final product, dimethylglyoxime. After synthesis, dimethylglyoxime is purified through crystallisation and filtration processes before being packaged for distribution.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

Dimethylglyoxime, or DMG, is produces primarily from the reaction of dimethylamine and diketene, which is described below:

1. Procurement of Starting Material: Diketene and Dimethylamine Reaction

Reaction Formula:

C4H4O2 + (CH3)2NH → C4H7NO

Explanation: Diketene (C4H4O2) reacts with dimethylamine ((CH3)2NH) to form N,N-dimethylacetamide (C4H7NO).

2. Formation of Dimethylglyoxime

Reaction Formula:

C4H7NO + NH2OH · HCl → C4H8N2O2 + HCl + H2O

Explanation: N,N-dimethylacetamide reacts with hydroxylamine hydrochloride (NH2OH·HCl) to yield dimethylglyoxime (C4H8N2O2), with hydrochloric acid (HCl) and water (H2O) as by-products.

3. Purification

The crude dimethylglyoxime is purified through recrystallisation using solvents such as ethanol or methanol to obtain the final pure product.

The dimethylglyoxime market is experiencing growth driven by its applications in analytical chemistry, particularly for detecting nickel, palladium, and platinum ions. In 2024, it was reported that approximately 60% of dimethylglyoxime's usage is in environmental applications, reflecting its importance in both analytical and ecological contexts. For instance, a recent study highlighted that over 1 million tests using dimethylglyoxime were conducted to monitor nickel levels in industrial wastewater. Moreover, dimethylglyoxime tests are available over the counter in pharmacies for detecting nickel release from jewellery, addressing skin sensitivity issues. Additionally, the demand for dimethylglyoxime in recycling processes for lithium-ion batteries is rising, with estimates suggesting that around 40% of battery recycling facilities are now employing this reagent to recover valuable metals like nickel and cobalt. These factors are contributing to market growth.

A detailed overview of production cost analysis that evaluates the manufacturing process of dimethylglyoxime is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, researchers at Baylor University recently developed a groundbreaking method for the efficient combustion of biofuels using a Swirl Burst (SB) injector, enabling the burning of glycerol/methanol blends with near-zero emissions. This innovative technology allows for ultra-clean combustion of high-viscosity fuels, achieving over 90% combustion efficiency without preheating. This advancement is poised to significantly reduce environmental impacts, improve cost-effectiveness in the biofuel industry, and impact dimethylglyoxime (DMG). Increased demand for biofuels may boost the need for efficient catalysts, potentially enhancing the use of DMG in nickel catalyst applications. Additionally, as glycerol becomes more widely used, there may be new opportunities for DMG production from glycerol by-products.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a dimethylglyoxime production plant:

Market Dynamics and Trends: Factors such as increasing use in nickel catalyst production are significantly affecting market conditions in the dimethylglyoxime sector. Nickel catalysts are needed in petroleum refining, where they are widely used in the hydrogenation of vegetable oils to produce margarine and other hydrogenated fats. The automotive industry further propels demand for nickel catalysts, particularly in catalytic converters, which reduce harmful vehicle emissions. Notably, approximately 70% of new vehicles globally are equipped with catalytic converters that rely on nickel-based catalysts for optimal performance.

Moreover, in 2025, the rapid adoption of electric vehicles (EVs) and renewable energy technologies is expected to drive the demand for key minerals like nickel and copper. Despite a 12% drop in the Philippines' nickel ore production to 25.7 million dry metric tons, industry leaders remain optimistic due to the critical role of these minerals in clean energy components. This surge in nickel demand directly impacts dimethylglyoxime, a compound essential for nickel testing and processing. By aligning with these evolving trends, businesses can strategically enhance their production plans to meet market needs effectively.

Profiling of Key Industry Players: Leading manufacturers in the dimethylglyoxime market include Merck KGaA, Aceto Corporation, Chemours Company, Jiangsu Jicuiyuan Chemical Co., Ltd., and Tianjin Pesticide Research Institute. These companies are engaged in the production and supply of dimethylglyoxime. Recently, BASF has also entered the dimethylglyoxime market to meet the growing demand for dimethylglyoxime across pharmaceuticals and environmental testing industries. With these key players actively participating in the market, the market competition remains robust.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in dimethylglyoxime prices are influenced by raw material costs, regulatory challenges, and market demand dynamics. The prices of key raw materials used in the production of dimethylglyoxime, such as acetaldehyde and formaldehyde, can be volatile due to supply chain disruptions, geopolitical tensions, and changes in production capacities. Any increase in the cost of these feedstocks directly impacts the overall production expenses for manufacturers.

Additionally, strict regulations related to the manufacturing, handling, and disposal of chemical substances can hinder production processes and increase operational costs. Compliance with environmental and safety standards often requires significant investment from manufacturers, which can be reflected in the pricing of dimethylglyoxime. Furthermore, fluctuations in demand from pharmaceuticals and electronic sectors can lead to price volatility as producers adjust their output to meet changing market needs. These factors collectively contribute to the pricing dynamics of dimethylglyoxime in the market.

Establishing a dimethylglyoxime manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of a dimethylglyoxime manufacturing facility must comply with various regulatory frameworks that govern production standards. These regulations include the Manufacture, Storage, and Import of Hazardous Chemicals Rules, which require manufacturers to identify major accident hazards and implement adequate safety measures to prevent incidents. Additionally, compliance with Occupational Safety and Health Administration (OSHA) standards is necessary, as these guidelines ensure safe working conditions and proper handling of hazardous materials.

Manufacturers must also adhere to environmental regulations that govern emissions and waste disposal, such as the Clean Air Act and the Resource Conservation and Recovery Act (RCRA) in the United States. These regulations mandate that any facility managing hazardous chemicals, including dimethylglyoxime, must develop safety reports and emergency response plans to mitigate risks associated with chemical exposure. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the dimethylglyoxime industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 2,699

USD 2,429

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 2,699

USD 2,429

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Our step-by-step guide will help you select, purchase, and access your reports swiftly, ensuring you get the information that drives your decisions, right when you need it.

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City,1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

United States

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

United States (Head Office)

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City, 1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

Share