Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Dextrose Powder Manufacturing Plant Project Report 2025 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a dextrose powder plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for dextrose powder is increasing due to growing awareness among consumers about the health risks associated with high sugar consumption, particularly obesity and diabetes. The World Health Organization (WHO) has reported that worldwide obesity has nearly tripled since 1975, with over 650 million adults classified as obese in 2016. Additionally, the International Diabetes Federation (IDF) states that approximately 537 million adults are living with diabetes, a number projected to rise to 783 million by 2045. These alarming statistics have heightened consumer awareness about the dangers of high sugar intake, prompting many to seek healthier alternatives and limit their sugary food intake. This shift is prompting food manufacturers to seek alternatives like dextrose, which can provide sweetness without the negative connotations of traditional sugars.

Other elements to consider while establishing a dextrose powder plant include raw material sourcing, workforce planning, and packaging. The production of dextrose powder primarily relies on key raw materials derived from starch sources, with corn being the most common. Corn starch undergoes hydrolysis, a process in which enzymes or acids break down the starch into simpler sugars, specifically glucose. This glucose is then crystallised into dextrose monohydrate, the primary form used in powder production. In addition to corn, other starchy sources such as potatoes, rice, and various vegetables can also be used for dextrose production. During production, binders like water or glucose syrup are often added to help agglomerate the dextrose particles during granulation. The combination of these raw materials and processes ensures the creation of high-purity dextrose powder that is widely used across food, pharmaceutical, and fermentation industries.

Moreover, to help stakeholders determine the economics of a dextrose powder plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Dextrose powder, a simple sugar derived from corn or wheat, is chemically identical to glucose and serves as a quick energy source for the body. It is commonly used in food products as a sweetener and has significant medical applications, particularly in intravenous solutions for treating low blood sugar and dehydration. Dextrose is also popular among athletes and bodybuilders for its rapid absorption and calorie density. It was first isolated in the early 19th century by French chemist Anselme Payen. It became widely recognised for its role in nutrition and medicine during the 20th century. Today, its production methods have evolved, leading to its current widespread use in various industries.

Dextrose powder, also known as D-glucose monohydrate, is a white crystalline powder with a sweet taste and no odour. It has a molecular formula of C6H12O6 and a molecular weight of 198.17. Dextrose is a monosaccharide, a type of carbohydrate, and is chemically identical to glucose found in the body. It has a density of 1.5 g/cm cube and is highly soluble in water, with a solubility of 450.5 g/L at 25°C. Dextrose has a melting point between 153-156°C and is stable when stored sealed in a dry environment at room temperature. It has a pH between 5.0-8.0 when dissolved in water at 25°C.

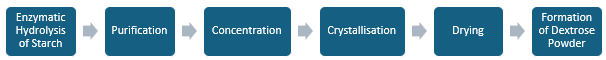

The production process of dextrose powder begins with starch, which is subjected to enzymatic hydrolysis. In this step, enzymes break down the starch into glucose. The resulting glucose solution is then purified to remove impurities, ensuring a high-quality product. Following purification, the glucose solution undergoes concentration to increase the sugar content. Once concentrated, the solution is cooled, allowing dextrose monohydrate to crystallise. The final step involves drying the dextrose crystals to produce a white powder with a sweet taste and bland odour.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

Below is the detailed description of the process of making dextrose powder:

1. Raw Materials

The raw materials required to produce dextrose powder include:

2. Hydrolysis of Starch

The primary step in the production of dextrose powder is the hydrolysis of starch. Starch is composed of long chains of glucose units linked together by glycosidic bonds. Hydrolysis breaks these bonds to release glucose (dextrose) molecules. This process can be achieved through either acid hydrolysis or enzymatic hydrolysis.

Acid Hydrolysis

In acid hydrolysis, starch is treated with dilute hydrochloric acid (HCl) in water. The acid breaks down the glycosidic bonds in starch, releasing dextrose (C6H12O6). The chemical reaction is as follows:

(C6H10O5)n + nH2O + nHCl → nC6H12O6 + nHCl

Enzymatic Hydrolysis

In enzymatic hydrolysis, enzymes such as alpha-amylase and glucoamylase are used to break down the starch molecules into dextrose. Alpha-amylase breaks down starch into shorter chains (dextrins), and glucoamylase further hydrolyses the dextrins into dextrose. The overall reaction is as follows:

(C6H10O5)n + nH2O → nC6H12O6 (with the help of enzymes)

3. Purification and Filtration

After hydrolysis, the dextrose solution is purified through filtration and decolorisation to remove impurities and by-products. Activated carbon and ion-exchange resins are commonly used to purify the solution.

4. Crystallization

The purified dextrose solution is then concentrated through evaporation to achieve a high concentration of dextrose. Crystallisation is induced by cooling the concentrated solution, leading to the formation of solid dextrose crystals.

5. Drying and Packaging

The dextrose crystals are separated from the solution using centrifugation and then dried to obtain dextrose powder. The powder is finally packaged in airtight containers to maintain its quality and prevent moisture absorption.

The dextrose powder market is driven by its diverse applications across in food and beverages, pharmaceuticals, and personal care industries. In the food sector, dextrose serves as a sweetener, bulking agent, and flavour enhancer in products such as baked goods, candies, sports drinks, and energy bars, appealing to consumers seeking quick energy sources. In the pharmaceutical industry, it is crucial for intravenous solutions that provide essential glucose to patients, as well as in oral rehydration solutions for treating dehydration. Additionally, dextrose is used in the production of fermentation processes for brewing beer and making bioethanol. In personal care, the growing demand for natural sweeteners and clean-label products propels market growth, as dextrose is favoured for its natural attributes in cosmetics, skincare formulations, and oral care products like toothpaste. Furthermore, the increasing trend of health and wellness, along with the rise in sports nutrition products, continues to enhance the market demand for dextrose powder.

A detailed overview of production cost analysis that evaluates the manufacturing process of dextrose powder is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, ongoing research and development are expanding the applications of dextrose powder into emerging sectors such as biofuels and cosmetics. In the biofuels sector, dextrose serves as a key substrate in the fermentation of corn to produce ethanol, a widely used biofuel. Additionally, it is used in microbial fermentation processes to produce advanced biofuels like butanol. Dextrose is also being explored in biofuel cells that convert glucose into electricity, providing power for small devices. In the cosmetics industry, dextrose monohydrate is increasingly incorporated into creams and lotions for its hydrating properties, improving skin texture and moisture retention. These developments indicate promising new market opportunities for stakeholders in this industry.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a dextrose powder production plant:

Market Dynamics and Trends: Growth factors such as expansion of product’s applications in food and pharmaceuticals are significantly affecting market conditions in the dextrose powder sector. Dextrose is widely used as a sweetener and flavour enhancer in baked goods, providing moisture and improving crust colour. In dairy products like flavoured milk, it balances sweetness, while in beverages, it replenishes energy quickly. Additionally, dextrose enhances texture and taste in confectionery and sauces. In the pharmaceutical sector, dextrose plays a vital role as an energy source in intravenous (IV) solutions and oral rehydration therapies. The growing healthcare needs due to rising health consciousness further propel the demand for dextrose in medicinal applications. The International Diabetes Federation highlights that 537 million adults are currently living with diabetes, which underscores the need for effective dietary management solutions that often include low-calorie sweeteners like dextrose. Understanding these factors helps businesses align their production plans with demands and trends in the dextrose powder market.

Profiling of Key Industry Players: Leading manufacturers in the dextrose powder market include prominent companies such as Cargill, Incorporated, Archer Daniels Midland Company (ADM), Ingredion Incorporated, and Tate & Lyle PLC. Other key players are Roquette Frères, Tereos, AGRANA Beteiligungs-AG, Gulshan Polyols Ltd., and Foodchem International Corporation. These companies are actively engaged in the production and distribution of dextrose, responding to the growing demand for natural sweeteners and functional ingredients across various sectors, including food, pharmaceuticals, and beverages.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in dextrose powder prices are influenced by several key factors, particularly the costs of essential raw materials such as corn and corn starch. The price trend of corn has shown some volatility; for instance, in late November 2024, corn futures dipped toward USD 4.20 per bushel amid ample supplies and demand concerns. The U.S. Department of Agriculture (USDA) projected the average corn price for the 2024 marketing year at USD 4.40 per bushel, down from USD 4.75 in 2023 and significantly lower than the high of USD 6.54 in 2022.

These trends reflect a larger supply of corn, with U.S. yields slightly reduced to 183.1 bushels per acre, resulting in an estimated production of 15.143 billion bushels for the 2024/25 marketing year. Additionally, large carryover stocks continue to suppress prices, contributing to an ongoing inventory buildup. Similarly, fluctuations in corn starch prices, which directly correlate with corn prices, further impact dextrose production costs. Disruptions in supply chains, such as reduced productivity at production facilities and transport issues caused by strikes at U.S. ports, have also led to significant price increases for dextrose powder. Analysis indicates that, despite short-term fluctuations in corn and dextrose prices, businesses must carefully navigate overall pricing strategies in the global market due to rising demand in the food and pharmaceutical sectors.

Establishing a dextrose powder manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of a dextrose powder manufacturing facility must comply with various regulatory frameworks that govern production standards. Key regulations include adherence to the Codex Alimentarius standards, which specify the essential composition and quality factors for powdered dextrose, such as a minimum reducing sugar content of 99.5% on a dry basis and strict limits on contaminants like arsenic and lead. Additionally, manufacturers must ensure compliance with local food safety regulations, which often require following the General Principles of Food Hygiene to maintain product safety and quality.

In many regions, including India, specific standards such as IS 874 (1992) outline the requirements for dextrose monohydrate used in pharmaceutical applications, detailing its purity, appearance, and freedom from contaminants. Furthermore, manufacturers must put the necessary labelling requirements that inform consumers about the product's composition, including any anti-caking agents used. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the dextrose powder industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 2,699

USD 2,429

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 2,699

USD 2,429

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Our step-by-step guide will help you select, purchase, and access your reports swiftly, ensuring you get the information that drives your decisions, right when you need it.

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City,1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

United States

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

United States (Head Office)

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City, 1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

Share