Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Copper Oxychloride Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a copper oxychloride plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

| Copper Oxychloride Product Details: | |

| Product Name | Copper Oxychloride |

| Chemical Formula | H6Cl2Cu4O6 |

| Molar Mass | 427.13 g/mol |

| Appearance and Color | Powder, Blue |

| CAS No. | 1332-40-7 |

| Melting Point | 300°C |

| Common Names | Colloidox, Blitox |

The demand for copper oxychloride is increasing due to several key factors, primarily its effectiveness as a fungicide in agriculture. As global food production needs are rising, driven by a projected increase of 2 billion people by 2040, the agricultural sector is facing significant pressure to enhance crop yields and protect against diseases. In 2024, it is estimated that fungal infections will affect approximately 30% of global crop production, with diseases such as downy mildew and late blight being particularly problematic. Downy mildew can lead to yield losses of up to 50% in susceptible crops like grapes and cucumbers, while late blight is responsible for devastating losses in potato and tomato production.

Countries in the Asia Pacific region, especially China and India, are experiencing rapid agricultural expansion. The Indian government has set ambitious targets under the PM Kisan Samman Nidhi scheme, aiming to double farmers' income by 2024. This has led to increased adoption of effective crop protection measures, including copper oxychloride, which is crucial for managing fungal diseases. In Latin America, countries like Brazil and Argentina are also witnessing strong demand for copper oxychloride due to rising agrochemical usage and modern farming practices.

Other elements to consider while establishing a copper oxychloride plant include raw material sourcing, workforce planning, and packaging. The production of copper oxychloride relies on several key raw materials, such as high-purity copper sources, including copper metal or copper salts, and hydrochloric acid. The manufacturing process begins with the reaction of copper with hydrochloric acid to form copper chloride. This is followed by a precipitation step where a base, such as sodium hydroxide, is added to produce copper oxychloride. The quality of these raw materials significantly impacts the final product’s purity and effectiveness.

Moreover, to help stakeholders determine the economics of a copper oxychloride plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Copper oxychloride is a widely used fungicide and bactericide in agriculture. It effectively combats various fungal diseases such as downy mildew and leaf spots in crops like tomatoes, grapes, and potatoes. The compound works by inhibiting spore germination through its interaction with enzymes, making it a critical tool for sustainable crop protection. Additionally, it serves as a precursor for other copper-based chemicals. Copper compounds have been used since ancient times; copper itself was first smelted around 5000 BC. Copper oxychloride was produced later for agricultural applications, gaining prominence in the 20th century as a reliable fungicide. Its natural occurrence in minerals like atacamite highlights its long-standing significance in both agriculture and industry.

Copper oxychloride, with the chemical formula Cu2(OH)3Cl, is a bluish-green powder that primarily functions as a fungicide in agriculture. It has a molecular weight of approximately 433.18 g/mol and appears as an odourless solid. The compound is insoluble in water but can dissolve in dilute acids and ammonium hydroxide, making it versatile for various applications. Its melting point is around 300 °C, at which it decomposes rather than melting. With a density ranging from 420 to 520 g/L, copper oxychloride is stable in neutral pH conditions but may decompose in alkaline environments. Additionally, it exhibits moderate toxicity to mammals and aquatic organisms, necessitating careful handling during use.

The production of copper oxychloride begins with the selection of raw materials, typically high-purity copper sources such as copper metal or salts. The process starts with a reaction with hydrochloric acid (HCl), where copper reacts to form copper chloride (CuCl2). Next, the copper chloride undergoes precipitation with sodium hydroxide (NaOH), resulting in the formation of copper oxychloride. The precipitate is then subjected to filtration to remove impurities, followed by washing to eliminate any remaining soluble salts. After washing, the product is crystallised to achieve the desired solid form. Subsequently, the crystallised copper oxychloride is dried to remove excess moisture and then milled to obtain the required particle size. Finally, rigorous quality control measures are implemented.

Read more about this report - Request a Free Sample

Copper oxychloride (Cu2(OH)3Cl) is a copper compound that is typically produced through a reaction involving copper(II) chloride (CuCl2) with copper(II) hydroxide (Cu(OH)2) or by reacting copper metal with chlorine gas.

1. Production of Copper Oxychloride via Copper(II) Chloride and Copper(II) Hydroxide

Copper oxychloride is commonly prepared by reacting copper(II) chloride with copper(II) hydroxide in the presence of water.

Reaction: 3 CuCl2 (aq) + 3 Cu(OH)2 (aq) → 2 Cu2(OH)3Cl (s) + 2 H2O (l)

Details:

2. Production via Chlorination of Copper

Copper oxychloride can also be produced by chlorinating copper metal (Cu) in the presence of chlorine gas (Cl2) and water.

Reaction: 2 Cu (s) + 4 Cl2 (g) + 2 H2O (l) → 2 Cu2(OH)3Cl (s) + 2 HCl (g)

Copper oxychloride is widely used in agriculture protecting crops from diseases such as downy mildew, leaf spots, and blight, particularly in fruits like grapes and tomatoes. For instance, global grape production is projected to reach approximately 75 million tonnes in 2024, with major producers including China (12.6 million tonnes), Italy (8.44 million tonnes), and the United States (5.37 million tonnes). Similarly, tomato production is expected to exceed 180 million tonnes, with leading producers like China, India, and the United States contributing significantly to this figure. Copper oxychloride is applied to prevent bacterial infections that can devastate these crops. Additionally, it serves as a soil amendment to address copper deficiencies essential for plant health. In industrial settings, it acts as a precursor for other copper compounds and is used in pigment production for ceramics and paints. The increasing demand for sustainable agricultural practices and the need for effective crop protection solutions are key drivers of the copper oxychloride market.

A detailed overview of production cost analysis that evaluates the manufacturing process of copper oxychloride is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, the World Bank recently stated that to meet the food demands of a projected global population of 9.7 billion by 2050, farmers will need to increase crop yields by 50% per hectare. This significant increase is crucial for ensuring food security. The reliance on agrochemicals, such as copper oxychloride, becomes essential in achieving these yield targets, especially in high-demand crops like tomatoes and grapes.

In 2021, global tomato production was approximately 182 million tonnes, with significant contributions from countries like China, India, and the United States. By 2050, production levels will need to rise to meet increased demand. Similarly, global grape production was around 77 million tonnes in 2021. The demand for grapes is also expected to rise due to increasing consumption rates and the growing popularity of wine and fresh grape consumption.

Copper oxychloride, specifically, is widely used as a fungicide to protect these crops from diseases. Additionally, the World Bank estimates that developing countries will require an average annual net investment of about USD 83 billion in agriculture to achieve necessary production increases. These trends can provide various opportunities for copper oxychloride producers.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a copper oxychloride production plant:

Market Dynamics and Trends: Rising potato production significantly impacts the copper oxychloride market, which is essential for managing crop diseases. In 2022, global potato production reached approximately 375 million tonnes, with China and India as the top producers, yielding 95.5 million tonnes and 56 million tonnes, respectively. Other notable producers included Russia with 18.9 million tonnes and the United States at 17.8 million tonnes. As demand for potatoes increases, so does the need for effective fungicides like copper oxychloride, which helps protect crops from diseases, thereby supporting higher yields and ensuring food security. Recently, in November 2023, experts from Punjab Agricultural University cautioned farmers about the risks of late blight disease affecting potato crops. This increasing awareness further drove demand for copper oxychloride. Understanding these factors helps businesses align their production plans with demands and trends in the copper oxychloride market.

Profiling of Key Industry Players: Leading manufacturers in the copper oxychloride market include Albaugh, LLC, IQV, Biota Agro Solutions Private Limited, Syngenta, and Greenriver Industry Co., Ltd. These companies are focusing on product innovation and sustainable formulations to meet growing agricultural demands.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Read more about this report - Request a Free Sample

Fluctuations in copper prices significantly impact the cost of copper oxychloride, as copper is a primary raw material in its production. When copper prices rise, the manufacturing costs for copper oxychloride increase, which can lead to higher product prices and reduced profit margins for manufacturers. This volatility creates challenges for companies striving to maintain competitive pricing in the market. Additionally, these price changes can affect the accessibility of copper oxychloride for farmers, ultimately influencing its market share and growth potential in the agricultural sector.

Establishing a copper oxychloride manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the copper oxychloride industry.

| Report Features | Coverage - Detailed Report |

| Product Name | Copper Oxychloride |

| Report Coverage | Manufacturing Process & Unit Operations: In-depth analysis of each step involved in the production from raw materials, including technical tests, mass balance, and key unit operations. |

| Plant Infrastructure & Development: Comprehensive review of land selection, site development, environmental impacts, construction costs, and project phasing. | |

| Plant Layout & Design: Factors influencing the plant layout, including space planning, machinery placement, and operational efficiency. | |

| Machinery & Equipment Requirements: Analysis of machinery needs for production, including costs, suppliers, and technological advancements. | |

| Raw Material Procurement & Costs: Detailed breakdown of raw material requirements, procurement strategies, supplier options, and cost structures. | |

| Packaging & Distribution: Insight into packaging requirements, material selection, procurement channels, and associated costs. | |

| Operational Costs & Resources: Examination of utility needs (water, electricity), transportation logistics, human resources, and other operational costs. | |

| Financial & Economic Analysis: Project investment costs, financial projections, income/expenditure forecasts, and cost-benefit analysis. | |

| Profitability & Risk Analysis: Financial performance metrics, including profitability margins, payback period, and sensitivity to market risks. | |

| Market & Competitive Landscape: Competitive positioning, market trends, regional breakdown, and strategic recommendations for market growth. | |

| Currency | USD (Data can also be provided in the local currency) |

| Customization Scope | The report can also be customised based on the requirements of the customer |

| Post-Sale Analyst Support | 10-12 weeks of post-sale analyst support available. |

| Data Access | Lifetime Access |

| Delivery Format | PDF and Excel through email (We can also provide the editable version of the report in PPT/Word format on special request) |

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

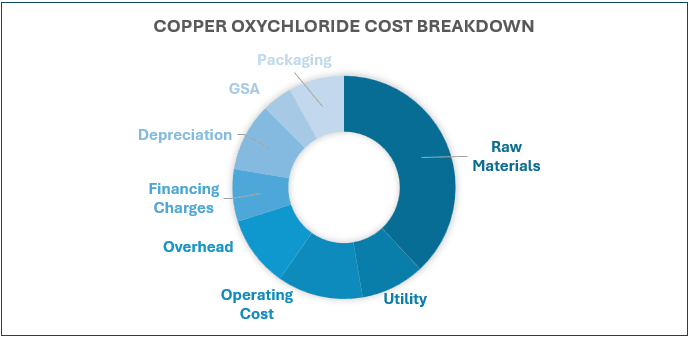

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share