Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Copper Hydroxide Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a copper hydroxide plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

| Copper Hydroxide Product Details: | |

| Product Name | Copper (II) Hydroxide |

| Chemical Formula | CuO2H2 |

| Molar Mass | 97.56 g/mol |

| Appearance and Color | Powder, Blue |

| CAS No. | 20427-59-2 |

| Melting Point | 160°C |

| Common Names | Parasol, Cuzin |

The demand for copper hydroxide is increasing due to expanding agrochemical industry.

Copper hydroxide is widely used as a fungicide in agriculture, effectively controlling fungal diseases such as powdery mildew and downy mildew on crops, particularly fruit trees and vegetables. In the United States, the Environmental Protection Agency (EPA) reported that copper-based fungicides account for approximately 25% of the total fungicide market share. As the global population is projected to reach around 9.7 billion by 2050, there is a pressing need for enhanced agricultural productivity, which drives the demand for effective crop protection chemicals like copper hydroxide.

Rapid industrial growth, particularly in developing countries in Asia, are also contributing to the rising demand for copper hydroxide. The United Nations estimates that by 2050, nearly 68% of the world's population will live in urban areas, leading to increased agricultural activities to meet food demands. Countries like India and China are experiencing significant industrial growth alongside agricultural advancements, further driving the need for effective pest management solutions.

Other elements to consider while establishing a copper hydroxide plant include raw material sourcing, workforce planning, and packaging. The production of copper hydroxide relies on several key raw materials, such as copper salts (like copper sulfate) and alkalis (such as sodium hydroxide). Copper sulfate, often sourced in its pentahydrate form (CuSO₄·5H₂O), serves as the primary source of copper ions in the production process. When mixed with sodium hydroxide, a precipitation reaction occurs, forming copper hydroxide as a bluish-green solid. In addition to copper sulfate and sodium hydroxide, other raw materials may include water for dissolving the salts and additives that enhance the stability of the final product. The quality of these raw materials directly impacts the efficiency of the manufacturing process and the purity of the copper hydroxide produced.

Moreover, to help stakeholders determine the economics of a copper hydroxide plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

However, challenges such as fluctuations in raw material prices and supply chain disruptions may threaten supply stability. To combat this, manufacturers of copper hydroxide can diversify their sourcing strategies by establishing relationships with multiple suppliers or investing in alternative raw materials that can be used in the production process. This approach can mitigate supply chain risks and ensure consistent production capabilities.

Copper hydroxide is a pale blue or bluish-green crystalline solid. It is primarily produced by adding sodium or potassium hydroxide to a copper salt solution. This compound is known for its low solubility in water and strong basic properties, making it useful in various applications, including agriculture as a fungicide and in the production of rayon, where it acts as a solvent for cellulose. Additionally, it serves as a colourant in ceramics and is used in the aquarium industry for controlling parasites. Copper hydroxide has been in demand since copper smelting began around 5000 BC. Alchemists first produced it by mixing copper sulfate and lye solutions. Its industrial production increased during the 17th and 18th centuries for use in pigments like blue verditer and Bremen green.

Copper hydroxide, with the chemical formula Cu(OH)2, is a pale blue or bluish-green crystalline solid known for its distinctive properties and various applications. Physically, it appears as a fine powder or crystalline solid with a density of 3.37 g/cm3 and a melting point of 80°C. It is insoluble in water, which contributes to its stability in various environments, and possesses a characteristic fishy odor. Chemically, copper hydroxide exhibits strong basicity, although its low solubility can make detection challenging in aqueous solutions. It readily reacts with acids to form copper salts; for instance, when it reacts with sulfuric acid, it produces copper sulfate and water. Additionally, copper hydroxide displays amphoteric behaviour, meaning it can react with both acids and bases. In concentrated alkalis, it dissolves to form complex ions.

The production of copper hydroxide typically begins with a solution of copper sulphate, often in its pentahydrate form (CuSO4⋅5H2OCuSO4⋅5H2O). The process starts by adding sodium hydroxide (NaOH) to the copper sulfate solution, which initiates a precipitation reaction. The mixture is then stirred thoroughly to ensure that the sodium hydroxide reacts completely with the copper sulfate, resulting in the formation of a bluish-green precipitate of copper hydroxide (Cu(OH)2).

Following the formation of the precipitate, the mixture is filtered to separate the solid copper hydroxide from the liquid. The precipitate is then washed with water to remove any impurities and excess sodium sulfate. After washing, the copper hydroxide is dried under vacuum conditions to obtain a pure final product. This method yields stable copper hydroxide, which can be used in various applications.

Read more about this report - Request a Free Sample

Copper hydroxide (Cu(OH)2) is commonly produced through a precipitation reaction, typically by reacting copper(II) salts (like copper(II) sulfate) with an alkali such as sodium hydroxide (NaOH). Below is a step-by-step process:

1. Precipitation of Copper Hydroxide

The most common method to produce copper hydroxide is by mixing an aqueous solution of copper(II) sulfate (CuSO4) with sodium hydroxide (NaOH). The reaction produces copper hydroxide as a blue precipitate.

Reaction: CuSO4 (aq) + 2 NaOH (aq) → Cu(OH)2 (s) + Na2SO4 (aq)

Details:

2. Production Using Copper(II) Chloride

Another method of producing copper hydroxide is by reacting copper(II) chloride (CuCl2) with sodium hydroxide (NaOH).

Reaction: CuCl2 (aq) + 2 NaOH (aq) → Cu(OH)2 (s) + 2 NaCl (aq)

Details:

Copper hydroxide is used in agriculture as a fungicide and pesticide, effectively controlling fungal diseases such as powdery mildew and downy mildew on crops, particularly fruit trees and vegetables. Its effectiveness as a biocide extends to the aquarium industry, where it is employed to eliminate external parasites like flukes and marine ich without harming fish, making it a preferred choice over other copper compounds that may be toxic to aquatic life. Additionally, copper hydroxide plays a crucial role in the textile industry as a mordant in dyeing processes and in the production of rayon, where it acts as a solvent for cellulose in the form of Schweizer’s reagent. The increasing demand for sustainable agricultural practices and the growth of the textile sector are primary drivers of the copper hydroxide market.

A detailed overview of production cost analysis that evaluates the manufacturing process of copper hydroxide is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, innovations in agricultural technology like the use of drones and satellite imagery allows farmers to apply fungicides more efficiently, reducing waste and improving crop health. As per industry reports, the application of precision agriculture can boost farm productivity by up to 30%. This increased productivity necessitates effective disease management solutions, thereby driving demand and production for copper hydroxide used in fungicides and bactericides.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a copper hydroxide production plant:

Market Dynamics and Trends: Factors such as shift towards sustainable agriculture practices are significantly affecting market conditions in the copper hydroxide sector. There is a growing emphasis on sustainable farming practices that reduces chemical inputs and increases crop yields. According to a report by the Food and Agriculture Organization (FAO), sustainable practices can increase crop yields by up to 58% while reducing environmental impact. Copper hydroxide is favoured due to its effectiveness and relatively lower toxicity compared to synthetic alternatives, making it an attractive option for farmers seeking eco-friendly solutions. Understanding these factors helps businesses align their production plans with demands and trends in the copper hydroxide market.

Profiling of Key Industry Players: Leading manufacturers of copper hydroxide include Vizag Chemical, known for its extensive distribution network in agriculture and industrial markets, and Vrik Pharma, which is engaged in speciality chemical production. Dhairya International offers copper hydroxide powder and granules, while Tambe Enterprises offers high-purity products for agricultural use. Triangulum Chemicals provides a variety of copper hydroxide products for industrial applications. Internationally, TIB Chemicals is renowned for its innovative solutions in this space. These companies are well-positioned to benefit from the growing demand of effective crop protection solutions.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Read more about this report - Request a Free Sample

Fluctuations in copper hydroxide prices are significantly influenced by the costs of essential raw materials such as copper oxide, sodium hydroxide, and sulfuric acid. The price of copper itself is a significant determinant. As of January 2025, copper prices are around USD 4.16 per pound, reflecting a slight decrease from earlier highs. Throughout 2024, copper experienced notable gains, even breaking the USD 5 mark in May due to tight supply and strong demand driven by the green energy transition and infrastructure projects. However, by the end of 2024, prices retreated to the USD 4 range as market dynamics shifted. Furthermore, regulatory pressures and the shift towards sustainable farming methods can affect the availability and pricing of raw materials, thereby influencing overall copper hydroxide prices in the market.

Establishing a copper hydroxide manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

Copper hydroxide manufacturers must comply with several key environmental regulations to ensure safe production and use of their products. Compliance with the Worker Protection Standard (WPS) is essential to protect workers from exposure, while adherence to the Environmental Protection Agency (EPA) regulations under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) ensures that products meet safety and efficacy standards. In the European Union, manufacturers must follow Directive 98/8/EC for biocidal products, which includes strict safety assessments and limits on hazardous impurities. Additionally, compliance with the National Pollutant Discharge Elimination System (NPDES) requires monitoring wastewater discharges to prevent excessive copper levels in water bodies. Finally, adherence to REACH regulations necessitates providing detailed Safety Data Sheets (SDS) that outline handling and emergency measures. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the copper hydroxide industry.

| Report Features | Coverage - Detailed Report |

| Product Name | Copper Hydroxide |

| Report Coverage | Manufacturing Process & Unit Operations: In-depth analysis of each step involved in the production from raw materials, including technical tests, mass balance, and key unit operations. |

| Plant Infrastructure & Development: Comprehensive review of land selection, site development, environmental impacts, construction costs, and project phasing. | |

| Plant Layout & Design: Factors influencing the plant layout, including space planning, machinery placement, and operational efficiency. | |

| Machinery & Equipment Requirements: Analysis of machinery needs for production, including costs, suppliers, and technological advancements. | |

| Raw Material Procurement & Costs: Detailed breakdown of raw material requirements, procurement strategies, supplier options, and cost structures. | |

| Packaging & Distribution: Insight into packaging requirements, material selection, procurement channels, and associated costs. | |

| Operational Costs & Resources: Examination of utility needs (water, electricity), transportation logistics, human resources, and other operational costs. | |

| Financial & Economic Analysis: Project investment costs, financial projections, income/expenditure forecasts, and cost-benefit analysis. | |

| Profitability & Risk Analysis: Financial performance metrics, including profitability margins, payback period, and sensitivity to market risks. | |

| Market & Competitive Landscape: Competitive positioning, market trends, regional breakdown, and strategic recommendations for market growth. | |

| Currency | USD (Data can also be provided in the local currency) |

| Customization Scope | The report can also be customised based on the requirements of the customer |

| Post-Sale Analyst Support | 10-12 weeks of post-sale analyst support available. |

| Data Access | Lifetime Access |

| Delivery Format | PDF and Excel through email (We can also provide the editable version of the report in PPT/Word format on special request) |

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

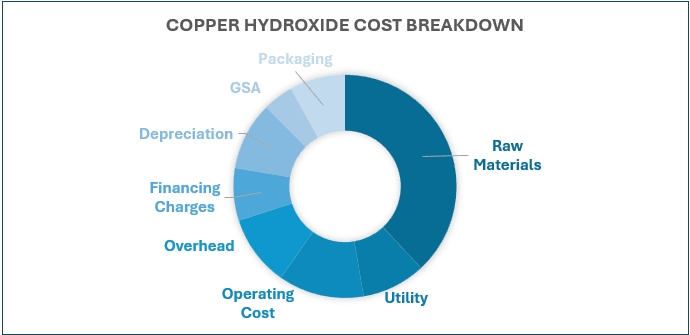

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Strategic Solutions for Informed Decision-Making

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share