Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Cooling Gel Pads Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a cooling gel pads plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The increasing demand for cooling gel pads can be attributed to a combination of health awareness, demographic shifts, and lifestyle changes. As consumers become more conscious of their health and wellness, there is a growing interest in non-invasive pain management solutions. Cooling gel pads are recognised for their effectiveness in providing relief from pain and inflammation without the side effects associated with pharmaceuticals. This trend is particularly significant among individuals suffering from chronic conditions such as arthritis or those recovering from sports injuries, who seek efficient and safe treatment options. As of 2024, over 58 million adults in the United States are affected by arthritis, with projections indicating that this number could reach 78 million by 2040. Osteoarthritis, the most common form, affects between 19% to 30% of adults over 45 years old, highlighting a substantial market for pain relief products like cooling gel pads.

Other elements to consider while establishing a cooling gel pads plant include raw material sourcing, workforce planning, and packaging. The production of cooling gel pads relies on key raw materials such as water, glycerol, sodium chloride, and polyacrylic acid. These ingredients are essential for creating the gel formulation that provides the desired cooling effect. Glycerol can be derived from natural sources like vegetable oils, while sodium chloride is commonly available as table salt. Polyacrylic acid is produced through chemical manufacturing processes. The manufacturing process involves mixing these components to form a hydrogel, which is then encased in flexible film casings made from materials like PVC or nylon.

Moreover, to help stakeholders determine the economics of a cooling gel pads plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Cooling gel pads are designed to provide a soothing, temperature-regulating effect for various applications. These pads typically contain a gel that absorbs heat from the body, creating a cooling sensation. They function effectively when the ambient temperature is lower than the body temperature, allowing heat to dissipate into the surrounding air once the user leaves the pad. This technology is particularly beneficial in hot weather or for individuals seeking relief from heat-related discomfort or minor injuries.

Cooling pads have evolved from traditional ice packs and water-based cooling methods as modern gel formulation leverages advancements in polymer science to enhance heat absorption and comfort. For instance, in October 2023, a new discreet cooling device designed to alleviate menopausal hot flushes was introduced by Brunel University student Aphra Hallam. The Zera Cooling Crescent uses skin-safe, reusable silicone gel pads and is portable enough to fit in a handbag. This device can be activated via Bluetooth through an accompanying app.

Cooling gel pads consist of a multi-layer structure, featuring an outer waterproof fabric shell (often made from nylon taffeta or polyester) and an inner hydrogel layer. The hydrogel is primarily composed of 30-40% water, 40-50% glycerol, 12-18% sodium chloride, and 1-4% polyacrylic acid. This composition allows the gel to absorb and dissipate body heat without the need for refrigeration.

Cooling gel pads maintain a temperature approximately 3 to 5 degrees Celsius below room temperature. Some models feature openings or channels within the gel layer to enhance breathability and airflow. Many cooling gel pads are also designed to be portable and lightweight. Moreover, cooling gel pads are often resistant to punctures and tears. They can typically withstand temperatures ranging from -20°C to 60°C and are easy to clean.

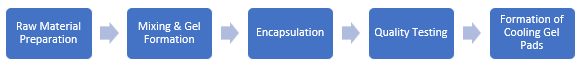

The production process of cooling gel pads begins with raw material preparation, where components such as poly-isocyanates, polyhydroxy compounds (with molecular weights ranging from 1,000 to 12,000), stabilisers, and fillers are gathered. The typical chemical composition of the gel includes 30-40% water, 40-50% glycerol, 12-18% sodium chloride, and 1-4% polyacrylic acid. Next, these materials are combined using a static or dynamic mixer, which is then subjected to the gel formation process, where it is allowed to set at room temperature for approximately 5 minutes to 24 hours. Once the gel has formed, it is poured into flexible film casings made from materials like PVC or nylon. These casings are sealed carefully to prevent any leakage. Then, the pads undergo quality control tests. Finally, after passing quality control checks, the cooling gel pads are packaged.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The process for producing cooling gel pads involves the following steps:

1. Preparation of Hydrogel

The first step involves the preparation of a hydrogel using a polymer, such as polyvinyl alcohol (PVA), and a crosslinking agent, such as borax (Na2B4O7). The chemical reaction is as follows:

n PVA (aq) + (B(OH)4)- + 2 Na+ → PVA-Borate Network (gel) + 2 NaOH (aq)

2. Incorporation of Cooling Agents

Cooling agents like menthol (C10H21O) or camphor (C10H14O) can be incorporated into the hydrogel. For example, the reaction of menthol with the hydrogel can be described as:

PVA-Borate Network + C10H14O → PVA-Borate-Menthol Gel (cooling gel pad)

3. Gel Pad Formation

The hydrogel containing the cooling agents is then poured into moulds to form gel pads. The mixture is allowed to set and solidify. This can be summarised as:

PVA-Borate-Menthol Gel (set) → Cooling Gel Pads (final product)

4. Packaging

Once the gel pads are formed and dried, they are cut into desired shapes and sizes, and then packaged for sale.

The applications of cooling gel pads are expanding significantly, driven by the rising incidence of orthopedic conditions and musculoskeletal disorders, particularly in regions like India, China, and Europe. In India, around 60 million people suffer from arthritis, with osteoarthritis being the most common form, significantly affecting mobility and quality of life. The ageing population is also a major concern; by 2025, approximately 140 million individuals in India will be over 60 years old, which is increasing the demand for effective pain management solutions. In China also, the prevalence of osteoporosis is alarming, with an estimated 200 million individuals affected, leading to a high incidence of fractures among the elderly. Reports indicate that over 1 million hip fractures occur annually in China alone, underscoring the urgent need for effective treatment options like cooling gel pads.

Moreover, government reports highlight that as the global population ages, expected to reach 2 billion people aged 60 or older by 2050, the demand for cooling gel pads as a non-invasive pain relief option will likely increase. This growing need for pain management strategies are driving market development. For instance, IHT Group launched patented cooling pad technology for hogs in North America in spring 2024. These pads feature aluminum tread plates over copper pipes that circulate water, improving animal welfare by reducing heat stress and enhancing productivity in livestock. Similarly, in August 2023, Kobayashi expanded its line of cooling gel sheets, which use a moisture-rich gel that lowers skin temperature significantly through evaporation, making them effective for fever relief and heat defense.

A detailed overview of production cost analysis that evaluates the manufacturing process of cooling gel pads is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a cooling gel pads production plant:

Market Dynamics and Trends: Factors such as expanding elderly population are significantly affecting market conditions in the cooling gel pads sector. Older adults often experience age-related health issues, making them more susceptible to joint pain and musculoskeletal disorders. Cooling gel pads offer a simple and effective solution for this demographic, allowing for independent use and easy application. Healthcare providers increasingly recommend these pads as part of pain management strategies for geriatric patients, further enhancing their appeal in this growing market segment. By 2025, it is estimated that 53.9% of individuals aged 75 and older will experience arthritis, making this demographic particularly reliant on effective pain management solutions. Understanding these demands and trends helps businesses align their production plans in the cooling gel pads market.

Profiling of Key Industry Players: Leading manufacturers of cooling gel pads include companies such as Dhruvraj Syndicate, Facmed Pharmaceuticals Pvt. Ltd., and Heptagon Healthcare Private Limited. Dhruvraj Syndicate offers a range of products designed for therapeutic use, while Heptagon Healthcare provides Rahat hot and cold gel pack, which is well-regarded in the market.

Recently, there has been a notable expansion in the cooling gel pad market, driven by increasing prevalence of conditions such as arthritis and sports injuries. By 2024, approximately 60 million people in India are expected to suffer from arthritis, with osteoarthritis being particularly common among older adults. This demographic shift is accompanied by an increase in sports participation, leading to a rise in sports-related injuries that necessitate effective recovery solutions like cooling gel pads. The demand is further fueled by the fact that around 140 million individuals in India will be over 60 years old by 2025, highlighting the urgent need for accessible pain management products.

The innovation landscape is also evolving, with new products entering the market that use advanced materials and technologies. For example, Kobayashi recently expanded its line of cooling gel sheets, which effectively lower skin temperature through evaporation, an important feature for users seeking relief from heat-related discomfort or minor injuries. Such advancements enhance the efficacy of cooling gel pads.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in cooling gel pad prices are influenced by several factors, including changes in raw material costs like glycerol and sodium chloride, advancements in manufacturing technology, and market demand driven by health and wellness trends. As consumer awareness increases and demand rises, prices may fluctuate accordingly, with e-commerce platforms also contributing to competitive pricing dynamics.

Establishing a cooling gel pads manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

Cooling gel pads must comply with several primary regulatory frameworks to ensure safety and efficacy in their production. In the United States, the Food and Drug Administration (FDA) regulates these products under Title 21 of the Code of Federal Regulations, which outlines standards for medical devices and consumer products. Additionally, manufacturers are required to adhere to Good Manufacturing Practices (GMP), ensuring that all production processes meet stringent quality standards, including proper handling of raw materials and robust quality control measures. Environmental regulations also play a crucial role, governing waste management and emissions to promote sustainable production practices. Furthermore, many manufacturers obtain ISO certification to demonstrate compliance with international quality management standards, which enhances product credibility in the market. These frameworks ensure that cooling gel pads are safe for consumer use and produced responsibly.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the cooling gel pads industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share