Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Cetyl Betaine Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a cetyl betaine plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for cetyl betaine is increasing due to its growing application in the cosmetics and personal care industries. Consumers are increasingly gravitating towards products that contain gentle and mild ingredients, leading to a rise in the use of cetyl betaine as a surfactant in shampoos, body washes, and skincare formulations. Its ability to enhance texture without causing irritation makes it a popular choice for hair care products. Additionally, the global shift towards clean beauty products has further propelled demand for cetyl betaine, as it is often derived from natural sources and is considered safer than traditional surfactants. Many brands are reformulating their products to be sulfate-free by leveraging cetyl betaine.

Other elements to consider while establishing a cetyl betaine plant include raw material sourcing, workforce planning, and packaging. The production of cetyl betaine relies on several key raw materials, such as cetyl dimethyl amine and coconut-derived fatty acids. Cetyl dimethyl amine is typically derived from the hydrogenation of vegetable oils, while coconut-derived fatty acids are extracted from coconuts.

Moreover, to help stakeholders determine the economics of a cetyl betaine plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Cetyl betaine, also known as hexadecyl betaine, is an amphoteric surfactant commonly used in cosmetics and personal care products. It acts as a mild cleansing agent, hair conditioner, and foam booster. Cetyl betaine is effective in trapping dirt and oil, making it easier to rinse away. It also provides skin and hair conditioning benefits by reducing static and improving manageability. Its chemical formula is C20H41NO2, comprising 20 carbon atoms, 41 hydrogen atoms, one nitrogen atom, and two oxygen atoms. Historically, cetyl betaine was developed as part of the broader class of betaines, which are derived from natural sources like sugar beets. Its use in cosmetics became prominent in the late 20th century as demand for mild surfactants grew.

Cetyl betaine appears as a colourless to pale yellow liquid with a density of approximately 1.0 to 1.1 grams per milliliter. The molecular weight of cetyl betaine is about 341.58 grams per mole, and its molecular formula is C20H41NO2. It has a flash point of around 150°C and is soluble in water at concentrations up to 30%. Cetyl betaine is stable under normal conditions (pH 4 to 10), although it can undergo hydrolysis and esterification at extreme pH levels. Its amphoteric nature allows it to act as both an acid and a base, forming zwitterionic structures in solution. Additionally, cetyl betaine has a low toxicity profile, with an LD50 greater than 5,000 mg/kg in oral studies, which makes it commonly used in cosmetics.

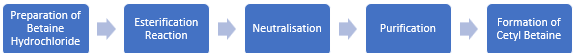

The production process of cetyl betaine begins with the preparation of betaine hydrochloride. This is achieved by reacting betaine with hydrochloric acid, resulting in a solution that is adjusted to a pH of 2 using concentrated HCl. Ethanol is then added to facilitate crystal growth, and the solution is chilled for up to 24 hours to form betaine hydrochloride crystals.

Next, hexadecanol (cetyl alcohol) is placed in a reactor and heated to approximately 70-80°C until melted. Betaine hydrochloride is added along with an acid catalyst, typically sulfuric acid, and the mixture is agitated and maintained at around 120°C for about 24 hours to allow for the esterification reaction to occur. After this reaction, the mixture is cooled to approximately 60°C, and potassium carbonate is introduced to neutralise the acid catalyst.

The product then undergoes purification with hot water to eliminate impurities. This process results in two layers forming: an organic layer containing cetyl betaine and an aqueous layer with by-products. The organic layer is filtered, and the product is then dissolved in hot ethyl acetate to remove any unreacted hexadecanol. Finally, the solution is cooled, filtered again, and concentrated through distillation to ensure the production of high quality cetyl betaine.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

Below is the process of making cetyl betaine:

Step 1: Synthesis of Cetyl Dimethylamine

Cetyl dimethylamine is synthesised by reacting cetyl alcohol with dimethylamine. The chemical reaction is shown below:

Chemical Reaction:

C16H33OH + (CH3)2NH → C16H33N(CH3)2 + H2O

Cetyl alcohol (C16H33OH) reacts with dimethylamine (CH3)2NH to form cetyl dimethylamine (C16H33N(CH3)2) and water (H2O).

Step 2: Quaternisation to form Cetyl Betaine

Cetyl dimethylamine is then reacted with chloroacetic acid to form cetyl betaine. The chemical reaction is shown below:

Chemical Reaction:

C16H33N(CH3)2 + ClCH2COOH → C16H33N(CH3)2CH2COO + HCl

Cetyl dimethylamine (C16H33N(CH3)2) reacts with chloroacetic acid (ClCH2COOH) to form cetyl betaine (C16H33N(CH3)2CH2COO) and hydrochloric acid (HCl).

Cetyl betaine is widely used in personal care products, particularly as a surfactant and conditioning agent. In the cosmetic industry, it is found in approximately 459 formulations registered with the FDA, predominantly in leave-on skin care products and hair conditioners. Its functionality includes antistatic properties, which help reduce static charges in hair, and cleansing capabilities that effectively remove dirt and oil. Studies indicate that cetyl betaine enhances skin hydration and improves hair manageability, which is why it is added in products with concentrations ranging from 0.0001% to 8.7%.

Additionally, cetyl betaine contributes to homocysteine remethylation, which can potentially lower cardiovascular risk, and is linked to reduced LDL cholesterol levels. Government reports also highlight its role in microbial biotechnology, where it serves as a methyl donor during fermentation processes. Cetyl betaine's role in functional foods is also gaining traction due to its health benefits, such as reducing homocysteine levels linked to cardiovascular health. Recent government reports highlight ongoing research into its potential in therapeutic applications, including HIV prevention and liver health support, further bolstering market interest.

A detailed overview of production cost analysis that evaluates the manufacturing process of cetyl betaine is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, in 2024, South Korea's K-beauty industry exported cosmetics worth USD 10.2, a 20.6% annual increase. China was the largest importer as the country purchased USD 2.5 billion worth of South Korean cosmetics, followed by the United States at USD 1.9 billion and Japan at USD 1 billion. This growth will likely boost demand for cetyl betaine as a key ingredient in personal care products. Moreover, cetyl betaine makers can expect increased opportunities for their products in the expanding market driven by K-beauty trends.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a cetyl betaine production plant:

Market Dynamics and Trends: Factors such as expanding personal care and cosmetics industries are significantly affecting market conditions in the cetyl betaine sector. In 2022, cosmetics and personal care products industry added approximately USD 308.7 billion to the U.S. GDP, reflecting a 15% increase since 2020. It supports around 4.6 million direct and indirect jobs. In terms of labor income, the industry generated about USD 203.3 billion, alongside contributing USD 82.3 billion in taxes at federal, state, and local levels. The expanding economic contributions of cosmetic sector in the U.S. are positively impacting the cetyl betaine market as well as it is a key ingredient in many personal care products.

Profiling of Key Industry Players: The cetyl betaine market is led by several prominent companies. BASF SE offers a variety of surfactants, including cetyl betaine. Evonik Industries AG is another key player, producing cetyl betaine as part of its extensive speciality chemicals portfolio aimed at cosmetics. Dow corporation, Kao Corporation, Solvay, Amino GmbH, Merck KGaA, and Stepan Company are other notable players contributing to the growth of the market.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in cetyl betaine prices are influenced by several key factors. Primarily, raw material costs play a significant role; changes in the prices of feedstocks like alkyl dimethyl t-amine can directly impact production expenses. Additionally, market dynamics, including supply chain disruptions and geopolitical issues, can affect the availability and pricing of these materials. Transportation and logistics costs also contribute to price variability, as increased shipping expenses can raise overall costs for manufacturers. Furthermore, broader economic factors such as inflation and shifting consumer demand for sustainable ingredients can lead to price adjustments. Together, these factors create a complex environment that affects cetyl betaine pricing in the market.

Establishing a cetyl betaine manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of a cetyl betaine manufacturing facility must comply with various regulatory frameworks to ensure safety, environmental protection, and product quality. Key regulations include the REACH Regulation in Europe, which mandates the registration of chemical substances to ensure safety for human health and the environment. Facilities must also adhere to Good Manufacturing Practices (cGMP) to maintain quality control and hygiene standards. In the U.S., compliance with EPA regulations is essential for chemical safety and environmental impact, while OSHA standards ensure worker safety regarding hazardous substances. Additionally, products containing cetyl betaine for cosmetic use must meet Cosmetic Ingredient Review (CIR) assessments for safety. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the cetyl betaine industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share