Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Carbon Tetrabromide Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a carbon tetrabromide plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for carbon tetrabromide is increasing due to its critical role in the pharmaceutical industry, where it is used as an essential intermediate in the synthesis of various drugs and active pharmaceutical ingredients, such as complex organic molecules and brominated derivatives. For example, carbon tetrabromide is utilized in the Appel reaction, which converts alcohols to alkyl bromides, and in the Corey-Fuchs reaction that transforms aldehydes into terminal alkynes. These reactions are essential for producing active pharmaceutical ingredients (APIs) used in medications for chronic diseases such as diabetes and cardiovascular conditions. The ongoing research and development activities in pharmaceuticals, spurred by the rising prevalence of health conditions and an ageing population, have heightened the need for chemical compounds like carbon tetrabromide.

For example, significant investments are being made in GLP-1 agonists for obesity and related issues, with obesity affecting 1 in 8 people globally. Companies like Sanofi are using digital twins to enhance predictive modelling in drug development. The global population aged 65 and older is projected to reach 1.5 billion by 2050, contributing to a surge in chronic diseases, which account for about 70% of all deaths worldwide. This demographic shift necessitates more effective pharmaceuticals, thereby boosting the demand for intermediates like carbon tetrabromide.

Other elements to consider while establishing a carbon tetrabromide plant include raw material sourcing, workforce planning, and packaging. The production of carbon tetrabromide relies on several key raw materials, such as methane and bromine. Methane, a primary feedstock, is typically derived from natural gas extraction and processing. This abundant hydrocarbon serves as the starting material for the bromination process that produces carbon tetrabromide. Bromine, on the other hand, is sourced from brine pools or salt lakes, with significant production occurring in countries like Israel and the United States. The bromination process involves reacting methane with bromine to yield carbon tetrabromide along with byproducts such as methyl bromide and dibromomethane. This method ensures a steady supply of carbon tetrabromide.

Moreover, to help stakeholders determine the economics of a carbon tetrabromide plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

However, challenges such as supply chain disruptions and raw material shortages may threaten supply stability for carbon tetrabromide production. Events like natural disasters, geopolitical tensions, or trade disputes can significantly impact the availability of essential materials, such as bromine and methane. For example, in 2021, geopolitical tensions in the Middle East affected the supply of bromine from Israel, which is one of the largest producers globally. Similarly, natural disasters such as hurricanes can disrupt natural gas production and processing facilities, leading to shortages of methane.

To combat these challenges, companies like Albemarle Corporation, a major producer of bromine and bromine-based compounds, have established multiple production facilities in different countries to mitigate risks associated with supply disruptions. By sourcing bromine from various locations, including the United States and China, they can ensure a more stable supply. Additionally, manufacturers can explore partnerships with local natural gas producers to secure a reliable source of methane. Implementing these strategies can help maintain consistent production levels in the market.

Carbon tetrabromide (CBr4), also known as tetrabromomethane, is a brominated hydrocarbon with various industrial applications. It is primarily produced through the bromination of methane, yielding byproducts like methyl bromide and dibromomethane. Carbon tetrabromide serves as a solvent for greases, waxes, and oils, and is used in the plastic and rubber industries for blowing and vulcanisation. Additionally, it plays a role in organic synthesis, particularly in reactions converting alcohols to alkyl bromides. Historically, carbon tetrabromide was first produced in 1865 by German chemist August Wilhelm von Hofmann. It gained prominence in the early 20th century for use as a solvent and in fire-resistant chemicals.

Carbon tetrabromide (CBr4) appears as colourless to yellow-brown crystals with a slight odour, a boiling point of approximately 190 °C (374 °F), and a melting point of about -9.5 °C (14.9 °F). It has a high specific gravity of 3.42, indicating it is denser than water. Chemically, carbon tetrabromide is non-polar due to its symmetrical tetrahedral structure, resulting in a dipole moment of 0 Debye. It is stable under normal conditions but can participate in reactions such as the Appel reaction, which converts alcohols to alkyl bromides when combined with triphenylphosphine.

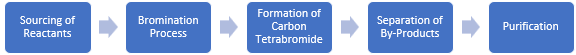

The production of carbon tetrabromide (CBr4) begins with sourcing methane (CH4) and bromine (Br2), which are reacted under controlled conditions. Typically, this direct bromination occurs at elevated temperatures, around 50-100 °C (122-212 °F), to facilitate the reaction. During this process, carbon tetrabromide is formed alongside byproducts such as methyl bromide (CH3Br) and dibromomethane (CH2Br2). The crude product then undergoes separation and purification techniques, such as distillation, to isolate high-purity carbon tetrabromide. The final product is obtained with a purity level exceeding 99%, making it suitable as a solvent and in the plastic and rubber industries.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

Below is the process of making carbon tetrabromide:

Step 1: Bromination of Methane or Carbon Disulfide

Carbon tetrabromide is generally produced by the bromination of methane (CH4) or carbon disulfide (CS2) using bromine (Br2) as the brominating agent.

Reaction Pathway 1: Bromination of Methane

The bromination of methane occurs in a radical substitution reaction where methane reacts with bromine to replace all the hydrogen atoms with bromine atoms, forming carbon tetrabromide (CBr4).

Chemical Reaction:

CH4 + 4Br2 → CBr4 + 4HBr

Methane (CH4) reacts with bromine (Br2) to form carbon tetrabromide (CBr4) and hydrogen bromide (HBr).

Reaction Pathway 2: Bromination of Carbon Disulfide

Another method involves the reaction of carbon disulfide with bromine, which leads to the production of carbon tetrabromide.

Chemical Reaction:

CS2 + 6Br2 → CBr4 + 2S2Br2

In this reaction, carbon disulfide (CS2) reacts with bromine (Br2) to form carbon tetrabromide (CBr4) and disulfur dibromide (S2Br2).

Carbon tetrabromide is widely used in the plastic and rubber industries for blowing agents and vulcanisation. Additionally, carbon tetrabromide serves as a chemical intermediate in organic synthesis, notably in the production of alkyl bromides and agrochemicals. According to the U.S. Environmental Protection Agency (EPA) annual reports, approximately 130 million pounds of carbon tetrabromide were produced in the United States as of recent years. Significant quantities were used in agricultural applications, such as grain fumigation and insecticides. Moreover, government data indicates that the demand for carbon tetrabromide is being influenced by regulatory pressures aimed at reducing hazardous substances, prompting manufacturers to innovate safer production methods. Also, the Montreal Protocol has led to a phase-out of ozone-depleting substances, which has impacted the production and use of carbon tetrabromide and has encouraged the development of eco-friendly alternatives.

A detailed overview of production cost analysis that evaluates the manufacturing process of carbon tetrabromide is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, regulatory frameworks are increasingly focusing on reducing the environmental footprint of agricultural chemicals. Many countries are implementing stricter guidelines on pesticide usage and encouraging the development of biopesticides and organic alternatives. The European Union has been actively promoting sustainable agricultural practices through its Green Deal, which aims to reduce chemical pesticide use by 50% by 2030. This shift also fosters the adoption of carbon tetrabromide across various applications, boosting production.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a carbon tetrabromide production plant:

Market Dynamics and Trends: Factors such as growing agrochemical sector are significantly affecting market conditions in the carbon tetrabromide sector. Carbon tetrabromide is used as a raw material in the production of pesticides and soil fumigants. The global agricultural consumption of pesticides is forecast to increase from approximately 4.3 million metric tons in 2023 to about 4.41 million metric tons by 2027. As the world population is projected to reach nearly 10 billion by 2050, the need for sustainable pest management solutions becomes increasingly pressing to ensure food security. Understanding these demands and trends helps businesses align their production plans in the carbon tetrabromide market.

Profiling of Key Industry Players: Leading companies in the carbon tetrabromide market include BASF SE, ICL Group, Chemtura Corporation, Albemarle Corporation, and Lanxess. Recently, BASF SE has strengthened its position in the market by acquiring Solvay's polyamide business, which includes the production of carbon tetrabromide. This strategic enhanced its offerings in the pharmaceutical and agrochemical sectors. Additionally, ICL Group launched a new grade of high-purity carbon tetrabromide tailoured for pharmaceutical applications. Chemtura Corporation has also expanded its production capacity. These companies are actively engaged in developing new products and improving their manufacturing processes to make profits on the rising demand for carbon tetrabromide across various applications.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in carbon tetrabromide prices are influenced by several key factors, including volatility in raw material prices, regulatory changes, and market demand dynamics. Disruptions in supply chains due to geopolitical tensions have previously led to spikes in bromine prices, which directly impact the production costs of carbon tetrabromide. Additionally, regulatory shifts regarding environmental standards can affect pricing. In the European Union, regulations like REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) require extensive testing and registration of chemical substances, which can increase production costs for manufacturers. If new regulations limit the use of certain brominated compounds due to environmental concerns, manufacturers may need to invest in alternative materials or processes, further driving up prices.

Establishing a carbon tetrabromide manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of a carbon tetrabromide manufacturing facility must comply with various regulatory frameworks governing production standards. Key regulations include the Clean Air Act, which mandates emission standards for hazardous air pollutants, requiring facilities to implement pollution control measures. The Clean Water Act regulates discharges into surface waters, necessitating permits for wastewater discharge and adherence to effluent limitations. Compliance with the Resource Conservation and Recovery Act (RCRA) is also essential, as it governs the management of hazardous waste generated during production. Additionally, adherence to safety standards such as the Hazard Communication Standard (HCS) is required, ensuring proper labelling and safety data sheets for chemicals. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the carbon tetrabromide industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share