Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Caramel Coffee Creamer Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a caramel coffee creamer plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for caramel coffee creamer is increasing due to the growing consumption of coffee globally. According to the National Coffee Association, approximately 66% of Americans consume coffee daily, a figure that has surged by nearly 14% since 2021. This rising trend is not limited to the U.S.; countries in the Asia-Pacific region, such as China, Japan, and India, are also witnessing a significant increase in coffee consumption as Western coffee culture is becoming more popular. This shift creates a greater demand for coffee enhancers like caramel creamers, which add flavour and richness to coffee beverages. Another contributing factor is the notable shift towards healthier coffee creamers. Many consumers are seeking non-dairy creamers made from almond, soy, or coconut milk due to rising awareness of lactose intolerance and dietary preferences.

Other elements to consider while establishing a caramel coffee creamer plant include raw material sourcing, workforce planning, and packaging. The production of caramel coffee creamer relies on several key raw materials, such as milk, heavy cream, and caramel sauce. Milk and heavy cream, essential for creating the creamy base of the creamer, are typically sourced from local dairy farms or large-scale dairy producers. Caramel sauce is made from ingredients like brown sugar, butter, and vanilla extract. This sauce is often produced in-house by manufacturers or sourced from suppliers offering high-quality caramel products. These raw materials ensure the production of optimal quality caramel coffee creamer.

Moreover, to help stakeholders determine the economics of a caramel coffee creamer plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Caramel coffee creamer features the rich, buttery flavour of caramel and has the smoothness of coffee creamer, which enhances the overall taste of coffee beverages. Popular in cafes and households, it serves as a convenient alternative to traditional cream or milk and appeals to those seeking a dairy-free option. Caramel originated from Arab mixtures of sugar and water centuries ago. However, the modern version, incorporating milk and cream, emerged around 1860. Coffee creamer itself became popular in the mid-20th century, with the first commercial product launched in 1950. Today, various companies have launched different creamers, which is driving the market expansion. For instance, in August 2024, Coffee Mate introduced Caramel Apple Crisp creamer, which combines sweet baked apple flavours with caramel notes. Similarly, in collaboration with Hershey, Coffee Mate launched Kit Kat Flavoured Creamer.

Caramel coffee creamer is typically a smooth, viscous liquid with a creamy texture, often having a rich caramel colour (RGB values around 139, 69, 19). The density ranges from 1.01 to 1.05 g/cm³, which makes it denser than water. The primary ingredients in the product include about 30-40% water, 20-30% sugar, and 10-15% vegetable oils, which contribute to its emulsification and stability. It is lactose-free, cholesterol-free, and gluten-free, making it appealing to various dietary needs. Additionally, it contains around 5-10% added sugars and flavourings, which enhance its sweetness and caramel flavour profile. Its pH typically hovers around 6-7, which ensures compatibility with coffee without altering its taste significantly.

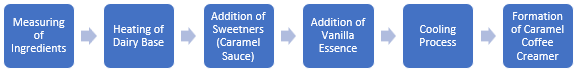

The production process of caramel coffee creamer begins with gathering essential ingredients: 2 cups of milk or half-and-half, 1 cup of sugar or 1 can (14 oz) of sweetened condensed milk, 1/2 cup of caramel sauce, and 1 teaspoon of vanilla extract. Next, in a medium saucepan, the dairy base is heated over medium-high heat until it reaches approximately 180°F (82°C), just below boiling, allowing the sugar to dissolve effectively. Once heated, the sweetener is added. Afterward, the caramel sauce is gradually whisked in. Once combined, the mixture is removed from heat, and 1 teaspoon of vanilla extract is stirred in to enhance the flavour profile. The creamer is then allowed to cool at room temperature for about 30 minutes before being transferred to a clean, airtight container.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The caramel coffee creamer market growth is largely attributed to the rising popularity of coffee consumption as about 66% of Americans consume coffee daily. The demand for flavoured options is also on the rise, with reports indicating that nearly 30% of consumers prefer flavoured coffee over unflavoured varieties. Additionally, the increasing lactose-intolerance levels has led to a surge in demand for non-dairy and plant-based creamers. For instance, in early 2023, Danone introduced new plant-based almond and coconut creamers under its Silk and So Delicious brands, while Chobani launched creamers in flavours like caramel macchiato and chocolate hazelnut. Furthermore, innovations in single-serve packaging and online shopping convenience have made it easier for consumers to enjoy flavoured creamers at home or on the go.

Moreover, the USDA reported that domestic coffee consumption in the U.S. reached approximately 25 million 60-kilogram bags in 2022, highlighting the robust demand for coffee and its accompaniments like creamers. Additionally, in 2024, coffee consumption in the United States reached a notable peak, with 67% of American adults reporting they had coffee in the past day, marking the highest level in over 20 years. The National Coffee Association's Spring 2024 report also highlighted that coffee consumption is particularly strong among mid-age demographics, with 66% of adults aged 25–39 drinking flavoured coffee in the past week. Overall, nearly three-quarters (73%) of Americans drink coffee daily, with an average consumption of about three cups per person. Ready-to-drink coffee options have also surged in popularity, also contributing to market growth.

A detailed overview of production cost analysis that evaluates the manufacturing process of caramel coffee creamer is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, total coffee consumption is expected to rise by 2.2% to about 177 million bags in the upcoming year. Luxembourg leads with a per capita consumption of approximately 6.5 kg (14 lbs). The United States, despite being one of the largest coffee consumers, ranks 67th globally in per capita consumption at about 4.7 kilograms (10.3 lbs) annually. The projected increase in global coffee consumption will boost the demand and production for caramel coffee creamer.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a caramel coffee creamer production plant:

Market Dynamics and Trends: The growing demand for plant-based creamers is significantly impacting the caramel coffee creamer sector. Notable players include Silk, known for its almond milk-based creamers that come in flavours like Caramel, Mocha, and Vanilla. Califia Farms features a range of creamers made from almond and oat milk, including popular flavors such as Caramel Macchiato, Hazelnut, and Cinnamon Roll. Oatly provides oat milk-based creamers with flavours like Sweet and Creamy, Mocha, and Caramel, while Planet Oat offers flavours such as Caramel and seasonal varieties like Gingerbread.

Additionally, Nut Pods offers dairy-free creamers in flavours like Caramel and French Vanilla. Brands like Milkadamia specialises in macadamia nut milk, while Elmhurst 1925 focuses on clean-label products made from simple ingredients. Even traditional brands like Coffee Mate are engaged in introducing plant-based options that include coconut and almond. These brands are responding to the increasing consumer preference for healthier, dairy-free alternatives, reshaping the market landscape for caramel coffee creamers.

Profiling of Key Industry Players: Leading manufacturers in the caramel coffee creamer market include major players such as Nestlé S.A., Danone, and Chobani LLC. These companies are known for their innovative products and significant market presence. Recently, in January 2023, Danone launched new almond and coconut-based coffee creamers. Chobani LLC also released several new flavours, including caramel macchiato, as part of its strategy to tap into the popular flavoured coffee creamer segment. Similarly, Nestlé's Coffee Mate brand has launched two limited-edition creamers in the flavours Thai Iced Coffee and Piña Colada, both designed to evoke tropical vacation vibes without caffeine or alcohol. These creamers will be available nationwide starting January 2025. Coffee mate also launched its first dairy-based Natural Bliss Pistachio Creamer on January 1, 2025. International Delight is also set to launch two new creamers in January 2025, namely, wedding cake creamer and chocolate covered strawberry creamer.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Production costs play a significant role in fluctuating caramel coffee creamer prices as the prices of raw materials and manufacturing expenses increase, manufacturers often pass these costs onto consumers, resulting in higher retail prices. Additionally, market demand and trends heavily impact pricing. Economic factors also contribute to price fluctuations; for instance, inflation or supply chain disruptions can elevate the costs of ingredients and production. Finally, shifting consumer preferences towards health natural and low-fat options, can further influence market prices, prompting manufacturers to adjust their pricing strategies.

Establishing a caramel coffee creamer manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of a caramel coffee creamer manufacturing facility must comply with various regulatory frameworks that govern production standards. These regulations include adherence to the Current Good Manufacturing Practices (CGMP) as outlined in the Code of Federal Regulations (CFR), specifically 21 CFR Part 110 and Part 117, which ensure that food products are produced safely and consistently. Manufacturers are also required to certify that their products meet specific quality and safety standards, including those related to ingredient composition and labeling, as mandated by the Federal Food, Drug, and Cosmetic (FD&C) Act and the Fair Packaging and Labeling Act.

In addition, facility must ensure that all ingredients are accurately labelled according to their common names and that any allergens are clearly identified to meet FDA allergen labelling requirements. Furthermore, packaging standards must be adhered to, ensuring that products are preserved correctly for consumer safety. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the caramel coffee creamer industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share