Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Capacitor Manufacturing Plant Project Report 2025 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics,” provides an in-depth and comprehensive examination of the financial and operational aspects of establishing capacitor plant.

The report is the result of extensive primary and secondary research, offering a detailed analysis of current market trends. It profiles key industry players, giving insights into their market strategies, production capacities, and financial performance, which are crucial for benchmarking and competitive analysis.

It delves into historical, current, and forecasted price trends, helping stakeholders understand market dynamics and price volatility. The report provides a thorough analysis of the mass balance and raw materials requirements, ensuring a clear understanding of the input-output ratios essential for efficient production. Detailed examinations of the various unit operations integral to the capacitor manufacturing process are included, highlighting process optimisation techniques and technological advancements.

The report presents a comprehensive capital cost analysis, detailing the financial investment required for setting up a capacitor plant. This includes an exhaustive breakdown of costs associated with raw materials, catchem, utilities, labour, packaging, transportation, land acquisition, construction, and machinery. Additionally, it offers an in-depth look at the operating costs, providing clarity on the recurring expenses involved in running the plant.

Projected profit margins and optimal product pricing strategies are outlined, offering guidance on maximising profitability. The report also addresses regulatory frameworks, environmental impacts, and sustainability measures pertinent to the capacitor industry.

A capacitor is a passive electronic component that stores electrical energy in an electric field. It consists of two conductors separated by an insulator. When a voltage is applied across the conductors, one accumulates a positive charge and the other a negative charge. The amount of charge stored depends on the capacitance, which is determined by the size of the conductors, the distance between them, and the properties of the insulating material. The earliest forms of capacitors were created in the 1740s, when European experimenters discovered that electric charge could be stored in water-filled glass jars known as Leyden jars. Over time, capacitors evolved from these early designs to include a variety of dielectric materials and construction methods, leading to the diverse range of capacitor types used in various electronic circuits for filtering, timing, and bypassing applications.

The fundamental property of capacitor is the capacitance, which is the measure of the amount of electrical charge a capacitor can store, measured in farads (F). Capacitors also have a working voltage, which is the maximum voltage that can be applied without causing damage. Another important property is the leakage current, which is the small amount of current that can pass through the dielectric material separating the conductors. Capacitors also have a specified working temperature range, within which they can operate effectively. Finally, some capacitors are polarised, meaning they require the correct polarity of the applied voltage to function properly. Also, capacitors can be made in a variety of shapes and sizes, using different dielectric materials such as ceramic, film, or electrolytic, each with their own advantages and disadvantages.

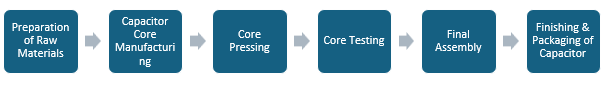

The process begins with the preparation of raw materials, where the metal parts such as the shell, bottom, and cover are cut and formed. These parts are then welded together to create the capacitor container. Next, the capacitor core is manufactured by winding the dielectric materials, such as aluminum foil and polypropylene film, into the capacitor components. The components are then assembled, and the capacitor core is subjected to withstand voltage tests to ensure quality.

After the core is assembled, it is pressed to the appropriate dimensions, and various non-electrical and electrical tests are performed to verify the capacitor's performance and safety. These tests may include noise detection, light wave detection, and high-frequency pulse current measurement. Finally, the capacitor undergoes a thorough inspection and is packaged for delivery.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The production of capacitors involves several steps, such as:

Step 1: Preparation of Aluminum Foil

High-purity aluminum foil is used as the electrode material in electrolytic capacitors. The aluminum foil is etched to increase its surface area.

Chemical reaction (etching): Al + 3 HCl → AlCl3 + 3/2 H2

Step 1: Formation of Aluminum Oxide Layer

The etched aluminum foil is anodised to form a thin layer of aluminum oxide (Alâ‚‚O3), which acts as the dielectric material.

Chemical reaction (anodising): 2 Al + 3 H2O → Al2O3 + 3 H2

Step 1: Winding or Stacking

The prepared electrode and dielectric materials are wound or stacked together to form the capacitor core. For electrolytic capacitors, a liquid or solid electrolyte is also included.

Step 2: Encapsulation

The capacitor core is encapsulated in a protective casing to ensure stability and protect it from environmental factors. The casing is often made of plastic or metal.

Step 3: Termination

The capacitor is then equipped with leads or terminals for electrical connection to circuits.

The primary applications for capacitors include the power generation and distribution sector, as well as the telecom, computer, consumer electronics, automotive, and industrial sectors. Capacitors play a crucial role in power generation and distribution, helping to prevent ripple currents and smooth out DC bus voltage variations. In the automotive industry, capacitors are used in electric vehicles to keep semiconductors safe and suppress harmful high frequency components generated by switching devices in the drive system. Additionally, the demand for capacitors is increasing due to rising demand for control circuits, inverter main circuits, switching mode power supplies, and computer motherboards. The capacitor market is driven by the increasing demand for consumer electronics products, growing demand for premium smartphones, and rising production of electric vehicles.

This production cost analysis report by Expert Market Research scrutinises the capacitor manufacturing process, offering a comprehensive overview necessary for stakeholders considering venturing into this sector. Based on the latest economic data, the report encompasses detailed insights into the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital investments, pricing strategies, and profit margins. This report is an indispensable resource for entrepreneurs, investors, researchers, consultants, business strategists, and all those who have any kind of stake in the capacitor industry. It equips them with essential information and strategic insights to effectively navigate the complexities of the market.

The following sections detail the comprehensive scope of the prefeasibility report for a capacitor production plant:

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the capacitor industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 2,699

USD 2,429

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 2,699

USD 2,429

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Our step-by-step guide will help you select, purchase, and access your reports swiftly, ensuring you get the information that drives your decisions, right when you need it.

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City,1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

United States

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

United States (Head Office)

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City, 1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

Share