Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Bamboo Straw Pipe Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a bamboo straw pipe plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

It is estimated that 500 million plastic straws are used daily in the United States alone, which translates to enough straws to fill over 127 school buses every day. These straws are typically used for a very short time and then discarded, contributing to the 15 million metric tons of plastic that enter the ocean each year. By 2025, experts predict that there will be one pound of plastic in the ocean for every three pounds of fish. Recently, around 7.5 million plastic straws were found on U.S. shorelines during a five-year cleanup project, highlighting their pervasive presence in marine environments. In contrast, bamboo straws are biodegradable and compostable, making them a much more sustainable option. Their use helps mitigate plastic waste significantly. Many households are actively transitioning from plastic to bamboo straws as part of their sustainability efforts, contributing to growth of the bamboo straw pipe market.

Other elements to consider while establishing a bamboo straw pipe plant include raw material sourcing, workforce planning, and packaging. The production of bamboo straw pipes relies primarily on bamboo stalks. Bamboo, particularly species like Moso bamboo (Phyllostachys edulis), is favoured for its rapid growth and renewability, making it an economical and sustainable choice. In addition, biodegradable additives such as polylactic acid (PLA) and polyhydroxyalkanoate (PHA) may be incorporated to enhance the straws' mechanical properties. A typical formulation might include 50-80% PLA and 10-40% PHA mixed with bamboo powder. Basic tools like knives for cutting, sandpaper for smoothing, and natural sealers such as beeswax are also essential for finishing the straws. The overall cost of these materials is relatively low, making bamboo straws an attractive option for both artisans and larger manufacturers.

Moreover, to help stakeholders determine the economics of a bamboo straw pipe plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Bamboo, belonging to the subfamily Bambusoideae of the grass family Poaceae, encompasses over 1,400 species across 115 genera. This diverse group of perennial plants is renowned for its rapid growth, with certain species capable of growing up to 91 cm in just 24 hours. Bamboo exhibits remarkable strength, with some species like Bambusa tulda reaching tensile strengths of up to 60,000 psi. Its hollow stems and high strength-to-weight ratio make it a valuable resource for construction, food, and various artistic applications, particularly in East and Southeast Asia, where it holds significant cultural and economic importance.

Historically, bamboo has been used for thousands of years for construction and crafts. Today, it is also used in making straws. Bamboo straw pipes are eco-friendly alternatives to plastic straws, made from the hollow stems of bamboo plants. They are biodegradable, reusable, and contribute to reducing plastic waste. Bamboo straws are gaining popularity in the sustainable living movement due to their minimal environmental impact and durability.

Bamboo straw pipes weigh approximately 5-10 grams and can be 20-25 cm in length, making them lightweight and easy to carry. They are durable, with a tensile strength of around 40,000 psi, and can withstand multiple uses, making them a sustainable alternative to plastic straws. Bamboo straws are heat resistant, allowing them to be used with beverages up to 100°C (212°F) without degrading. Chemically, they are biodegradable within 3-6 months, breaking down naturally without leaving harmful residues. Additionally, bamboo contains a natural antimicrobial compound called "bamboo kun," which helps resist mold and bacteria, ensuring hygienic use.

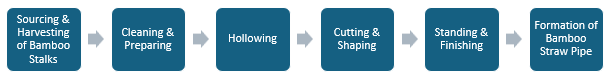

The production process of bamboo straw pipes begins with sourcing and harvesting mature bamboo stalks, such as Moso bamboo, which are then cut to desired lengths. After harvesting, the bamboo is cleaned to remove dirt and impurities, followed by hollowing out the stalks to create cylindrical tubes while maintaining a consistent diameter. The hollowed bamboo is then cut into straw lengths and the ends are smoothed for safety. Next, the straws are sanded to eliminate rough edges and optionally treated with natural oils for added protection. Afterward, the straws are air-dried to remove moisture, followed by a quality control inspection to ensure consistency and durability. Finally, the finished bamboo straws are packaged for sale or distribution.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The bamboo straw pipe market is driven by the increasing demand for sustainable and eco-friendly alternatives to single-use plastics, particularly in the food and beverage industry. Bamboo straws, being biodegradable and reusable, serve as an excellent substitute for plastic straws, aligning with global efforts to reduce plastic waste. They are widely used in restaurants, cafes, and events for serving beverages like juices and smoothies. Additionally, the rise of e-commerce and social media marketing has further propelled the market.

A detailed overview of production cost analysis that evaluates the manufacturing process of bamboo straw pipe is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological ninnovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, numerous countries have implemented bans on plastic straws to combat plastic pollution. In the United States alone, plastic straws rank among the top ten items found during coastal cleanups globally. While plastic straws account for only about 0.025% of total plastic waste entering oceans each year, their visibility in marine environments make them a focal point for anti-plastic campaigns.

In 2020, Starbucks phased out plastic straws in favour of paper alternatives across its 28,000 branches globally. Similarly, California has enacted legislation requiring full-service restaurants to ask customers if they want a plastic straw instead of automatically providing one. Seattle became one of the first major U.S. cities to implement a ban on plastic straws in July 2018, mandating that restaurants and bars use compostable or reusable alternatives instead. On an international scale, countries like Vanuatu and the Seychelles have outright banned plastic straws. In Europe, McDonald's has eliminated plastic straws in its UK and Ireland locations. These examples highlight a significant shift away from plastics, propelling bamboo straw pipe expansion.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a bamboo straw pipe production plant:

Market Dynamics and Trends: Technological innovations significantly impact the bamboo straw pipe sector through advancements such as 3D printing and biodegradable coatings. 3D printing allows for customisable straw designs, enhancing functionality and brand appeal. Biodegradable coatings improve the durability and usability of bamboo straws, making them more resistant to moisture and wear. Additionally, recycling technologies enable the upcycling of used bamboo straws into new products, promoting a circular economy. These innovations not only address environmental concerns but also meet growing consumer demand for sustainable alternatives to single-use plastics, driving market growth in the bamboo straw sector. Understanding these factors helps businesses align their production plans with demands and trends in the bamboo straw pipe market.

Profiling of Key Industry Players: Leading manufacturers in this sector are dedicated to producing high-quality and eco-friendly bamboo straws. Notable players are bambu, Arbhu Enterprises, Oceans Republic, Bamboo Straws Company, Bamboo Straw Co., Greenhouse Eco Products, Simply Straws, and StrawFree.

Arbhu Enterprises produces premium bamboo straws for India and Hengshun Bamboo Products Factory offers a variety of bamboo products. Other important manufacturers include Yedhant International, KK Enterprise, Bambooology Private Limited, Soulway Enterprise, Namaste Bamboo, Pioneer Paper Cup, and B. M. Traders.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in bamboo straw pipe prices are influenced by several key factors, particularly the costs of essential raw materials such as bamboo stalks. The availability and quality of these bamboo stalks can significantly impact production costs, with prices ranging from USD 0.05 to USD 0.10 per straw depending on geographical location. Labour costs also play a crucial role, as skilled artisans are needed for the meticulous crafting of each straw, adding an additional USD 0.02 to USD 0.05 per unit. Furthermore, production volume affects pricing as larger production runs can lower per-unit costs due to economies of scale. Other factors include quality control measures, packaging, and branding expenses, which can further influence the overall cost structure of bamboo straws.

Establishing a bamboo straw pipe manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of a bamboo straw pipe manufacturing facility must adhere to various regulatory frameworks. Key regulations include the FSSAI guidelines for food safety in India, ISO/PRF 16830 for the quality of bamboo products, and Jamaican Standards, which governs local bamboo production. In the U.S., compliance with FDA regulations for food contact materials, EPA environmental standards, and OSHA workplace safety guidelines is essential. Adherence to EU Regulation (EC) No 1935/2004 for food safety, local zoning laws, and certification standards from organisations like the Forest Stewardship Council (FSC) further ensure safe production of bamboo straws.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the bamboo straw pipe industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share