Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Baby Laundry Detergent Manufacturing Plant Project Report 2025 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing a baby laundry detergent plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The increasing demand for baby laundry detergent can be linked to increasing awareness of infant skin sensitivity and rising birth rates. Research indicates that babies have thinner skin and a less developed skin barrier, which can lead to increased susceptibility to irritants. This awareness has driven parents to seek out hypoallergenic and gentle detergents specifically formulated for babies. The global birth rate is projected to be approximately 16.65 births per 1,000 people in 2024, reflecting a slight increase from previous years. This rise in birth rates contributes directly to the demand for baby-specific products, including laundry detergents. Countries with high birth rates, such as Niger at 46.6 births per 1,000 inhabitants, underscore the growing population of infants requiring care products. This trend highlights the importance of ensuring safe and effective cleaning solutions for the increasing number of households with babies.

Other elements to consider while establishing a baby laundry detergent plant include raw material sourcing, workforce planning, and packaging. The production of baby laundry detergent relies on several key raw materials. One primary ingredient is surfactants, which are essential for cleaning and stain removal. Common surfactants used in baby laundry detergents include sodium dodecylbenzene sulfonate, sodium lauryl sulfate, and amino acid-based surfactants. Amino acid surfactants have gained popularity due to their gentle nature and biodegradability, making them suitable for sensitive skin and reducing environmental impact.

Additionally, many formulations incorporate plant-based ingredients such as coconut-derived cleansers and bio-enzymes. These natural components not only enhance cleaning efficiency but also ensure that the detergent is free from harmful chemicals like parabens, phosphates, and synthetic fragrances, which can irritate a baby's skin. The careful selection of these raw materials is crucial in producing baby laundry detergents that meet safety standards while effectively cleaning clothes.

Moreover, to help stakeholders determine the economics of a baby laundry detergent plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Baby laundry detergent is specifically formulated to be gentle on sensitive skin while effectively removing stains from baby clothes. These detergents typically avoid harsh chemicals, dyes, and fragrances, making them suitable for infants who are prone to skin irritation. Parents often choose these products to ensure their baby's garments are clean and safe, especially given the frequency of laundry required for infants. The first laundry detergent, Dreft, was introduced by Procter & Gamble in the 1930s, targeting delicate fabrics. The development of baby-specific detergents followed as awareness of children's skin sensitivities grew. Today, various brands offer specialised formulas catering to the needs of infants and toddlers.

Baby laundry detergents are available in 2 main forms: liquid and powder, with liquid detergents often preferred by 70% of parents for their quick dissolving ability in cold water. The formulas are generally smooth and free flowing, ensuring easy application and rinsing. Baby detergents contain mild surfactants that effectively lift stains while being gentle on sensitive skin. 95% of these detergents are free of harsh chemicals such as phosphates, bleach, and fragrances, reducing the risk of irritation. Many formulas, up to 85%, include natural antibacterial ingredients, such as Neem, to ensure hygienic cleaning without harmful chemicals. The use of baby-specific detergents has increased by 30% over the past decade as awareness of children's skin sensitivities has grown.

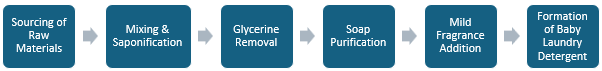

The production process of baby laundry detergent begins with the selection of raw materials, including oils (like coconut and olive oil), alkali (such as sodium hydroxide), water, gentle surfactants, and natural additives like neem extract and aloe vera. These ingredients are mixed and heated to initiate saponification, where the oils react with the alkali to produce soap and glycerine. The glycerine is then removed, typically through evaporation or centrifugation, followed by the purification of the soap to eliminate impurities. A mild, baby-safe fragrance is added before the detergent is packaged in suitable bottles. Finally, the packaged detergent is stored in a clean, dry environment and distributed to retailers.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

Below is the detailed process of making baby laundry detergent, such as:

1. Selection of Surfactants

The primary cleaning agents in laundry detergents are surfactants. For baby laundry detergent, mild and non-irritating surfactants are chosen. Commonly used surfactants include Sodium Lauryl Sulfate (SLS), Sodium Laureth Sulfate (SLES), and Cocamidopropyl Betaine.

Chemical Formula for Sodium Lauryl Sulfate (SLS):

C12H25NaO4S

Chemical Formula for Sodium Laureth Sulfate (SLES):

C14H29NaO5S

Chemical Reaction (Formation of SLS):

C12H25OH + H2SO4 → C12H25OSO3H + H2O (Dodecyl hydrogen sulfate formation)

C12H25OSO3H + NaOH → C12H25OSO3Na + H2O (Sodium lauryl sulfate formation)

2. Addition of Builders and Softeners

Builders are added to enhance the cleaning efficiency by softening water and maintaining alkalinity. Common builders include Sodium Carbonate (Na2CO3) and Sodium Citrate (Na3C6H5O7). Fabric softeners, like glycerin, are also added to keep baby clothes soft.

Chemical Formula for Sodium Carbonate (Na2CO3):

Na2CO3

Chemical Reaction (with Water Hardness Ions):

Ca2+ + Na2CO3 → CaCO3 + 2Na+ (Calcium carbonate precipitation)

3. Incorporation of Enzymes

Enzymes such as proteases, lipases, and amylases are incorporated to break down proteins, fats, and carbohydrates, respectively. These enzymes help remove stains from baby clothes.

Chemical Reaction (Protease Action on Protein Stains):

Protein + H2O → Amino Acids (Protease-catalysed hydrolysis)

4. Blending

All the ingredients, including surfactants, builders, softeners, and enzymes, are mixed in large industrial blenders to create a homogeneous detergent mixture. The temperature and mixing speed are controlled to ensure proper blending.

5. pH Adjustment and Addition of Fragrance

The pH of the detergent is adjusted to a mild level (typically pH 7-8) using citric acid or sodium hydroxide. Baby laundry detergent often contains a mild fragrance, added in small quantities to ensure it is gentle on the skin.

Chemical Reaction (pH adjustment with Citric Acid):

C6H8O7 + NaOH → C6H7O7Na + H2O

6. Packaging

The finished detergent is filled into bottles or containers, labeled, and sealed. The packaging process is conducted under hygienic conditions to prevent contamination. The packaged detergent is then ready for distribution.

The baby laundry detergent market is experiencing significant growth, driven by increasing parental awareness regarding the unique needs of infant clothing, leading to a demand for specialised products that are gentle on sensitive skin and free from harsh chemicals. For example, brands like Babyganics and The Honest Company offer hypoallergenic formulations that cater to this market. Additionally, the rising birth rates globally and a growing preference for eco-friendly products further fuel market expansion. As per industry reports, the countries with the highest birth rates in 2024 are predominantly located in Africa, with Niger leading at an impressive 46.6 births per 1,000 population. Following Niger are Angola with 41.1, Benin at 40.3, and Mali at 40 births per 1,000. This trend of high birth rates is significant as it correlates with the increasing demand for baby-specific products, including laundry detergents.

A detailed overview of production cost analysis that evaluates the manufacturing process of baby laundry detergent is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, Tide Free & Clear is a trusted hypoallergenic laundry detergent that has gained popularity for its effectiveness and safety, particularly for sensitive skin.

This formula is free of dyes, perfumes, phthalates, and phosphates, making it an excellent choice for babies and individuals prone to skin irritation. It is recognized by both the National Eczema Association and the National Psoriasis Foundation and is frequently recommended by pediatricians for its gentle yet effective properties. Despite its mild formulation, Tide Free & Clear boasts impressive stain-fighting capabilities, easily tackling tough stains such as those from breastfed newborns. The popularity of Tide Free & Clear in the baby laundry detergent market can significantly benefit stakeholders by tapping into the growing demand for hypoallergenic and gentle cleaning solutions.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for a baby laundry detergent production plant:

Market Dynamics and Trends: Growth factors such as expansion of online shopping platforms has significantly affected market conditions in the baby laundry detergent sector. Platforms like Amazon, Firstcry and Mee Mee offer a variety of baby-specific detergents. For instance, Mother Sparsh provides a plant-powered laundry detergent made with natural ingredients. Similarly, The Moms Co. features a detergent enriched with bio-enzymes and neem extract, ensuring gentle yet effective cleaning. The rise in e-commerce has also led to a 30% increase in online sales of baby care products. Understanding these factors helps businesses align their production plans with demands and trends in the baby laundry detergent market.

Profiling of Key Industry Players: Leading manufacturers like Procter & Gamble, Henkel, and Mother Sparsh are included in the baby laundry detergent report. Recently, Unilever launched innovative laundry sheets under its brands, such as Robijn and Dirt Is Good, to meet the growing consumer demand for good cleaning solutions. Similarly, Kao launched the Attack ZERO liquid laundry detergent, which is formulated with their proprietary Bio IOS technology. This detergent is gentle on fabrics, which makes it suitable for baby clothes.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in baby laundry detergent prices are influenced by several key factors, particularly the costs of essential raw materials such as petroleum-based chemicals and surfactants. For instance, the price of surfactants can range from USD 1.50 to USD 3.00 per kilogram, depending on market conditions. Additionally, the shift towards eco-friendly ingredients often leads to higher production costs, with natural surfactants priced around USD 5.00 to USD 8.00 per kilogram. Economic factors like inflation can also impact retail prices, which typically range from USD 10 to USD 20 for a standard bottle of baby laundry detergent. As parents increasingly seek hypoallergenic options, manufacturers must balance quality and cost to remain competitive.

Establishing a baby laundry detergent manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of a baby laundry detergent manufacturing facility must comply with various regulatory frameworks. In the United States, the Environmental Protection Agency (EPA) regulates laundry detergents through its Safer Choice Program, certifying products that meet stringent safety and environmental standards. Additionally, the Federal Hazardous Substances Act (FHSA) mandates clear hazard warnings and usage instructions on product labels, ensuring consumers are informed about potential risks.

In California, the Cleaning Products Right to Know Act requires manufacturers to disclose all ingredients on product labels and websites. Compliance with Occupational Safety and Health Administration (OSHA) standards is also essential for ensuring safe handling practices in industrial settings. Internationally, manufacturers must adhere to standards set by the Bureau of Indian Standards (BIS) in India, which includes requirements for biodegradable ingredients and safety evaluations for irritant potential. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the baby laundry detergent industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 2,699

USD 2,429

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 2,699

USD 2,429

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Our step-by-step guide will help you select, purchase, and access your reports swiftly, ensuring you get the information that drives your decisions, right when you need it.

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City,1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

United States

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

United States (Head Office)

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City, 1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

Share