Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Ammonium Hydrosulfide Manufacturing Plant Project Report 2026 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics,” provides an in-depth and comprehensive examination of the financial and operational aspects of establishing ammonium hydrosulfide plant.

The report is the result of extensive primary and secondary research, offering a detailed analysis of current market trends. It profiles key industry players, giving insights into their market strategies, production capacities, and financial performance, which are crucial for benchmarking and competitive analysis.

It delves into historical, current, and forecasted price trends, helping stakeholders understand market dynamics and price volatility. The report provides a thorough analysis of the mass balance and raw materials requirements, ensuring a clear understanding of the input-output ratios essential for efficient production. Detailed examinations of the various unit operations integral to the ammonium hydrosulfide manufacturing process are included, highlighting process optimisation techniques and technological advancements.

The report presents a comprehensive capital cost analysis, detailing the financial investment required for setting up a ammonium hydrosulfide plant. This includes an exhaustive breakdown of costs associated with raw materials, catchem, utilities, labour, packaging, transportation, land acquisition, construction, and machinery. Additionally, it offers an in-depth look at the operating costs, providing clarity on the recurring expenses involved in running the plant.

Projected profit margins and optimal product pricing strategies are outlined, offering guidance on maximising profitability. The report also addresses regulatory frameworks, environmental impacts, and sustainability measures pertinent to the ammonium hydrosulfide industry.

Ammonium hydrosulfide, with the formula NH4HS, is a colourless, water-soluble compound that forms micaceous crystals. It is primarily produced by passing hydrogen sulfide through concentrated ammonia. This compound is significant in astrochemistry, as it is believed to be a component of the cloud decks on gas giants like Jupiter and Saturn. Ammonium hydrosulfide is also used in photography as a component in photographic developers, in the textile industry for dyeing processes and as a reducing agent, and in chemical synthesis as a precursor in the production of other sulfur-containing compounds.

Ammonium hydrosulfide, with the chemical formula NH4HS, is an inorganic compound that features both ammonium ions (NH4+) and hydrosulfide ions (HS-). It typically exists as a colourless to yellowish crystalline solid with a molar mass of approximately 51.11 g/mol. This compound is highly toxic and corrosive, requiring careful handling to avoid exposure, as it can irritate the skin, eyes, and respiratory system. Ammonium hydrosulfide has a melting point that decomposes before reaching 0°C, and a boiling point of approximately 40°C, but it decomposes before reaching this temperature. It has a density of around 1 g/mL and is soluble in water and alcohol, but insoluble in organic solvents like toluene and benzene.

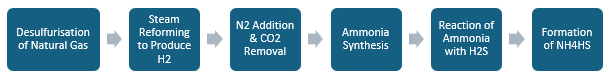

The production of ammonium hydrosulfide (NH4HS) begins with the desulfurisation of natural gas, where sulfur compounds, primarily hydrogen sulfide (H2S), are removed using materials like activated carbon or zinc oxide beds. Next, the desulfurised natural gas is mixed with steam and heated, passing over a nickel catalyst to convert approximately 70% of the methane (CH4) into hydrogen (H2) and carbon dioxide (CO2).

Next, in the secondary reforming, the reformed gas is mixed with preheated air to achieve the desired hydrogen to nitrogen (H2:N2) ratio of 3:1 in the final synthesis gas. The subsequent step is the shift reaction, where carbon monoxide (CO) in the synthesis gas is converted to carbon dioxide (CO2) through a water-gas shift reaction. The CO2 is then removed using an MDEA (methyldiethanolamine) solution. Once the gas is purified, the compressed hydrogen and nitrogen are catalytically converted to ammonia (NH3) over an iron catalyst. Finally, ammonia is reacted with hydrogen sulfide (H2S) to produce the desired ammonium hydrosulfide (NH4HS) solution.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

The production of ammonium hydrosulfide involves several processes, such as:

Step 1: Preparation of Ammonia (NH3)

Ammonia is typically produced through the Haber-Bosch process, which involves the direct combination of nitrogen (N2) and hydrogen (H2) gases. The reaction is carried out under high pressure and temperature in the presence of a catalyst.

Chemical Reaction: N2 (g) + 3H2 (g) → 2NH3 (g)

Step 2: Preparation of Hydrogen Sulfide (H2S)

Hydrogen sulfide is produced by reacting sulfur with hydrogen gas at high temperatures. Another common method involves the reaction of sulfur-containing compounds with hydrogen.

Chemical Reaction: S (s) + H2 (g) → H2S (g)

Step 3: Production of Ammonium Hydrosulfide (NH4HS)

Ammonium hydrosulfide is produced by bubbling hydrogen sulfide gas through a solution of ammonia in water. The reaction is typically carried out at room temperature and atmospheric pressure.

Chemical Reaction: NH3 (aq) + H2S (g) → NH4HS (aq)

One of the main uses of ammonium hydrosulfide is in the mining industry, where it serves as a flotation agent for the extraction of metals such as copper and zinc, enhancing recovery rates. Additionally, it is used in the production of speciality chemicals and as a reagent in analytical chemistry. The growing demand for ammonium hydrosulfide in photo development processes and its role in wastewater treatment further contribute to market growth. Factors such as technological advancements and increasing industrial activities are also propelling the market for ammonium hydrosulfide.

This production cost analysis report by Expert Market Research scrutinises the ammonium hydrosulfide manufacturing process, offering a comprehensive overview necessary for stakeholders considering venturing into this sector. Based on the latest economic data, the report encompasses detailed insights into the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital investments, pricing strategies, and profit margins. This report is an indispensable resource for entrepreneurs, investors, researchers, consultants, business strategists, and all those who have any kind of stake in the ammonium hydrosulfide industry. It equips them with essential information and strategic insights to effectively navigate the complexities of the market.

The following sections detail the comprehensive scope of the prefeasibility report for a ammonium hydrosulfide production plant:

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the ammonium hydrosulfide industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 5,699

USD 4,844

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 5,699

USD 4,844

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 6,799

USD 5,779

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 8,899

USD 7,564

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Share