Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Aluminium Bromide Manufacturing Plant Project Report 2025 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing an aluminium bromide plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for aluminium bromide is increasing due to its versatile applications in various chemical processes. One of its primary uses is as a catalyst in Friedel-Crafts reactions, which are crucial for synthesising aromatic compounds. For example, in the production of pharmaceuticals and fragrances, aluminium bromide facilitates the formation of carbon-carbon bonds, enhancing the efficiency of these reactions. Aluminium bromide serves as a Lewis acid, promoting reactions that require electron pair acceptance, thereby increasing the reactivity of substrates. Its role in polymerisation processes further underscores its importance; it can initiate polymer chains, making it valuable in the production of specialty chemicals. Moreover, the compound exhibits high hygroscopicity, absorbing moisture from the air and forming hydrated forms that are essential in various applications. As industries continue to prioritise efficient and sustainable chemical processes, the reliance on aluminium bromide is expected to grow, reflecting its critical role in modern chemistry.

Other elements to consider while establishing an aluminium bromide plant include raw material sourcing, workforce planning, and packaging. The production of aluminium bromide relies on several key raw materials, such as aluminium (Al) and bromine (Br2). Aluminium is typically sourced from bauxite, a mineral that contains a high percentage of aluminium oxide. The aluminium used in production is often in powdered form to enhance its reactivity during the synthesis process. Bromine, on the other hand, is usually obtained from natural brine sources or produced through chemical processes. The reaction between powdered aluminium and liquid bromine at elevated temperatures produces aluminium bromide, highlighting the importance of securing high-quality raw materials to ensure product purity and efficiency in production.

Moreover, to help stakeholders determine the economics of an aluminium bromide plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

However, challenges such as disruptions in raw material availability, particularly aluminium (Al) and bromine (Br2), along with rising energy costs, which have surged by over 30% in recent years, threaten the stability of aluminium bromide plant operations. To address these issues, manufacturers can explore alternative sources for key ingredients, which would reduce dependency on fossil fuels and enhance supply chain resilience. Implementing this strategy not only mitigates risks associated with raw material shortages but also aligns with sustainability goals in the production of aluminium bromide.

Aluminium bromide, with the chemical formula AlBr3, is a pale yellow solid that is hygroscopic and sublime. It is primarily used as a catalyst in organic synthesis, particularly in Friedel-Crafts reactions, and as a brominating agent. The compound is notably toxic and can cause severe burns upon contact with skin or eyes. In its anhydrous form, it appears as a colourless solid, while in solution it can be corrosive to various materials. Aluminium bromide was first produced in the 19th century when chemists were exploring halogen compounds. However, its industrial applications emerged in the early 20th century and today, it plays a crucial role in various chemical processes.

Properties of Aluminium Bromide

AlBr3 is a colourless to pale yellow solid with a pungent odour. It turns into gas without turning into liquid upon heating, which makes it hygroscopic and highly sublime. The anhydrous form has a melting point of 97.5°C, a boiling point of 255°C, and a density of 3.2 g/cm cube. Additionally, it has a molar mass of 266.69 g/mol. Moreover, aluminium bromide acts as a strong Lewis acid with a dissociation constant (pKa) of approximately -6.5 in water, where it readily hydrolyses to produce hydrobromic acid (HBr). It can also react with carbon tetrachloride (CCl4) to form carbon tetrabromide (CBr4) and aluminium chloride (AlCl3). These properties demonstrate its reactivity in varied organic synthesis and catalysis.

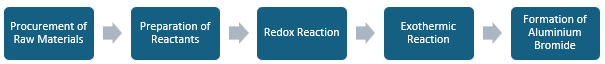

The production process of aluminium bromide begins with the procurement of raw materials, such as aluminium (Al) and bromine (Br2). The aluminium is typically powdered to enhance reactivity, while bromine is used in its liquid form. The powdered aluminium is then introduced into a reaction vessel which contains liquid bromine. This initiates a redox reaction that produces aluminium bromide. Once the aluminium bromide is formed, it often exists in a dimeric state as Al2Br6. The product then undergoes a purification process to eliminate any unreacted materials or impurities. A quality control check is later performed to assess the purity of the product. Once the AlBr3 product meets the required purity standards, it is stored and packaged for distribution.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

Below are the steps and chemical reactions involved in the industrial production of aluminium bromide:

Step 1: Preparation of Reactants

The primary reactants needed for this synthesis are aluminium (Al) and bromine (Br2). Typically, high-purity aluminium is used, and bromine is introduced in its diatomic molecular form as a gas. The reaction is highly exothermic, so it is essential to control the temperature carefully.

Step 2: Reaction between Aluminium and Bromine

Aluminium and bromine react directly according to the following chemical equation:

2 Al (s) + 3 Br2 (g) → 2 AlBr3 (s)

In this reaction, solid aluminium combines with gaseous bromine to form solid aluminium bromide. The reaction is typically performed in a controlled environment to prevent the escape of bromine gas.

Step 3: Reaction Conditions

The reaction between aluminium and bromine is carried out at elevated temperatures. The aluminium is often heated to initiate the reaction, as bromine will react vigorously with hot aluminium. To ensure high purity of the aluminium bromide, an inert atmosphere such as nitrogen may be used.

Step 4: Collection

Upon completion, the product, aluminium bromide, is collected and can undergo further purification if necessary.

The aluminium bromide market growth is propelled by its widespread use as a catalyst in chemical and pharmaceutical synthesis. For example, it plays a critical role in production of anti-inflammatory medications and antibiotics, such as ibuprofen and naproxen. The product’s demand is also high in agrochemical production. In countries like India, aluminium bromide aids in the creation of advanced crop protection chemicals, including herbicides like flumioxazin and insecticides such as neonicotinoids, which help enhance crop yield and resist pests. European Union regulations, such as the Sustainable Use of Pesticide Regulation (SUR) and Regulation EC 1107/2009, further support its use in herbicides/pesticides. Furthermore, in Europe, aluminium bromide is increasingly used in flame retardants due to regulations like the EcoDesign Directive, which restricts the use of hazardous substances in products. Due to these regulations, the compound is commonly applied in electronic casings and automotive parts to prevent fire spread. The growing market for electric vehicles (EVs) also sees exploration of aluminium bromide as a raw material in lithium-ion battery electrolytes. This could improve battery efficiency and stability and hence, can benefit EV manufacturers across regions.

A detailed overview of production cost analysis that evaluates the manufacturing process of aluminium bromide is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins. For instance, in December 2024, Emirates Global Aluminium (EGA) has commenced construction of 10 pilot reduction cells for its next-generation EX smelting technology at Al Taweelah, aimed at enhancing Industry 4.0 capabilities in the aluminium sector. This innovative technology is designed to produce more aluminium with reduced energy consumption and lower emissions, incorporating advanced IoT sensors for real-time data collection.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for an aluminium bromide production plant:

Market Dynamics and Trends: Growth factors such as the increasing use of aluminium bromide in sectors such as pharmaceuticals, agrochemicals, and chemical synthesis significantly affect market conditions in the aluminium bromide sector. In the pharmaceutical industry, aluminium bromide serves as a catalyst in the production of active pharmaceutical ingredients (APIs) and is used in formulations for antacids. For instance, it helps reduce stomach acidity, providing relief for conditions like ulcers and heartburn, making it a crucial component in many over-the-counter medications. In agrochemicals, aluminium bromide is used as a brominating agent to synthesize various pesticides and herbicides. It aids in creating herbicides like flumioxazin and insecticides such as neonicotinoids, which enhance agricultural productivity. Regulatory support from the European Union for sustainable pesticide use further boosts its demand in this sector. Understanding these demands helps businesses align their production plans with demands and trends in the aluminium bromide market.

Profiling of Key Industry Players: Leading manufacturers like Alpha Chemika, Tulip Chemicals Pvt. Ltd., Vishnu Priya Chemicals Pvt. Ltd., and Marine Chemicals are included in the aluminium bromide report. These players are focusing on improving their market presence by increasing their production capacities, engaging in mergers and acquisitions, and investing in technologies. For instance, the recent registration of new flumioxazin herbicide products highlights the ongoing innovation and expansion efforts within the agrochemical sector, which directly impacts the demand for aluminium bromide as a key ingredient in pesticide formulations. In October 2024, the U.S. Environmental Protection Agency (EPA) approved several new flumioxazin formulations, including Sipcam Flumioxazin 4 SC and Sipcam Flumioxazin 51% WDG, aimed at enhancing weed control in crops such as soybeans and peanuts. As these new products enter the market, the increased utilisation of flumioxazin in agricultural practices is expected to drive demand for aluminium bromide.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in aluminium bromide prices are influenced by several key factors, particularly the costs of essential raw materials such as aluminium and bromine. As of October 2024, aluminium prices were reported at approximately USD 2,400 per metric ton, reflecting a 15% increase compared to early 2024. This surge can be attributed to increased energy prices, which have risen by 20% due to supply chain disruptions and conflicts in major producing regions.

Meanwhile, bromine prices have also fluctuated, driven by heightened demand from the agrochemical sector, particularly for herbicides like flumioxazin, which use aluminium bromide in their formulations. Reports indicate that bromine prices reached around USD 6,000 per metric ton in September 2024, marking a 10% increase since the beginning of the year. Consequently, the average price of aluminium bromide has been rising steadily, with estimates suggesting that by 2025, prices could reach approximately USD 8,000 per ton, driven by ongoing supply constraints and growing demand across various applications. These price trends can drive manufacturers to adjust pricing strategies and manage production expenses.

Establishing an aluminium bromide manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

The establishment of an aluminium bromide manufacturing facility must comply with various regulatory frameworks that govern production standards and environmental impacts. In the United States, the Occupational Safety and Health Administration (OSHA) sets forth regulations that require manufacturers to implement safety protocols for handling hazardous materials, including aluminium bromide, which is classified as a highly corrosive chemical. For instance, OSHA's standards mandate the use of appropriate personal protective equipment (PPE) to protect workers from exposure, including gloves, goggles, and respiratory protection, especially considering that aluminium bromide can cause severe skin burns and eye damage upon contact.

Additionally, compliance with the Environmental Protection Agency (EPA) regulations is mandatory. Facilities must adhere to the Resource Conservation and Recovery Act (RCRA) guidelines for the proper disposal of hazardous waste generated during production. This includes ensuring that any waste containing aluminium bromide is disposed of in an approved waste disposal facility to prevent environmental contamination. Furthermore, under the Toxic Substances Control Act (TSCA), manufacturers must report any new uses of aluminium bromide to the EPA for assessment before commencing production. Compliance with these regulations not only ensures legal operation but also enhances product safety and marketability.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the aluminium bromide industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 2,699

USD 2,429

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 2,699

USD 2,429

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Our step-by-step guide will help you select, purchase, and access your reports swiftly, ensuring you get the information that drives your decisions, right when you need it.

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City,1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

United States

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

United States (Head Office)

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City, 1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

Share