Consumer Insights

Uncover trends and behaviors shaping consumer choices today

Procurement Insights

Optimize your sourcing strategy with key market data

Industry Stats

Stay ahead with the latest trends and market analysis.

The Expert Market Research report, titled “Allylamine Manufacturing Plant Project Report 2025 Edition: Industry Trends, Capital Investment, Price Trends, Manufacturing Process, Raw Materials Requirement, Plant Setup, Operating Cost, and Revenue Statistics” includes various aspects that are critical for establishing an allylamine plant. These include infrastructure requirements, transportation requirements, utility specifications, and financial and economic analysis, among others.

The demand for allylamine is increasing due to its extensive use in the pharmaceutical and agricultural sectors. In pharmaceuticals, allylamine derivatives, such as terbinafine, are widely used in antifungal medications, effectively treating conditions like athlete's foot and ringworm. In 2024, athlete's foot, also known as tinea pedis, affects around 10% of the global population, with higher rates observed among adolescents and adults. The infection is primarily caused by dermatophytes such as Trichophyton rubrum and Trichophyton mentagrophytes, which thrive in warm, moist environments like locker rooms and swimming pools.

Recent studies indicate that about 15% of regular swimmers tested positive for dermatophytes, highlighting the risk associated with communal bathing facilities. As participation in sports increases, the demand for effective treatments for athlete's foot continues to grow. Similarly, ringworm, another common fungal infection caused by dermatophytes, affects about 20%-25% of the population as of 2024. The Centers for Disease Control and Prevention (CDC) reported approximately 690 hospitalisations related to dermatophytosis (ringworm), alongside nearly 5 million outpatient visits, highlighting the infection's widespread impact on healthcare systems. Terbinafine has been proven to be more effective in treating such problems than traditional antifungal agents like griseofulvin.

Other elements to consider while establishing an allylamine plant include raw material sourcing, workforce planning, and packaging. The production of allylamine relies on several key raw materials, such as allyl chloride and ammonia. Allyl chloride serves as the primary alkyl halide in the synthesis process, reacting with ammonia to produce allylamine. Other raw materials include carboxylic acid allyl esters, which can be used in alternative synthesis methods involving transition metal catalysts. These esters, such as allyl acetate and diallyl phthalate, contribute to the production of various allylamine derivatives.

Moreover, to help stakeholders determine the economics of an allylamine plant, project funding, capital investments, and operating expenses are analyzed. Projections for income and expenditure, along with a detailed breakdown of fixed and variable costs, direct and indirect expenses, and profit and loss analysis, enable stakeholders to comprehend the financial health and sustainability of a business. These projections serve as a strategic tool for evaluating future profitability, assessing cash flow needs, and identifying potential financial risks.

Allylamine is a colourless liquid with a strong ammonia-like odour. It is the simplest stable unsaturated amine and is used in the production of pharmaceuticals and other chemicals. Allylamine is toxic by inhalation, ingestion, and skin absorption, and it irritates skin, eyes, and mucous membranes. Allylamine was first produced by treating allyl chloride with ammonia followed by distillation. It can also be prepared by the reaction of allyl chloride with hexamine or by hydrolysis of allyl isothiocyanate.

Allylamine has a molecular formula of C3H5NH2 and a density of 0.7630 g/cm³. It has a melting point of -88°C and a boiling point between 55-58°C. Allylamine is highly flammable, and its vapors are heavier than air and can form explosive mixtures with air. It is a lachrymatory agent and a skin irritant, with an oral LD50 of 106 mg/kg for rats.

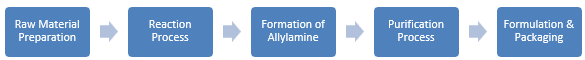

The production process of allylamine begins with the preparation of raw materials, specifically allyl chloride and ammonia or hexamine. The next step involves a chemical reaction where allyl chloride is treated with ammonia to produce allylamine, or alternatively, allyl chloride can be reacted with hexamine. Following the reaction, purification is necessary, which typically involves distilling the reaction mixture to separate allylamine from any by-products. Quality control measures are then implemented to test the purity and potency of the allylamine. Once verified, the compound is formulated into various forms, such as liquids or powders, before being packaged for distribution. Finally, the packaged allylamine is distributed.

Read more about this report - REQUEST FREE SAMPLE COPY IN PDF

Below is a detailed overview of the processes involved in the production of allylamine:

1. Synthesis of Allylamine from Allyl Chloride

One of the most common methods to produce allylamine is the nucleophilic substitution of allyl chloride (C3H5Cl) with ammonia (NH3). The reaction is typically carried out under pressure and at elevated temperatures.

Chemical Reaction:

C3H5Cl (allyl chloride) + NH3 → C3H5NH2 (allylamine) + HCl

2. Catalytic Amination of Propylene

Another industrial process for producing allylamine involves the catalytic amination of propylene (C3H6) with ammonia (NH3) in the presence of a catalyst. This process takes place at high temperatures and pressures, using catalysts like nickel or cobalt.

Chemical Reaction:

C3H6 (propylene) + NH3 → C3H5NH2 (allylamine) + H2 (catalysis)

3. Purification of Allylamine

After the synthesis, the crude allylamine product is purified to remove impurities such as unreacted ammonia, allyl chloride, or propylene, as well as by-products. Common purification techniques include distillation and extraction.

4. Storage and Handling

Allylamine is a highly reactive compound and must be stored in sealed containers under nitrogen or other inert atmospheres to prevent polymerisation and other unwanted reactions.

Allylamine has a wide range of applications, particularly in the chemical and pharmaceutical industries. It is primarily used in the synthesis of functionalised allylamines, which have important pharmaceutical applications, including drugs like flunarizine for migraine relief and naftifine for antifungal treatments. Additionally, allylamine is used in the production of polymers, such as polyallylamine, which are promising materials for membranes in reverse osmosis processes. The market for allylamine is driven by the growing demand for pharmaceuticals and advanced materials, as well as an increasing focus on research and development in chemical synthesis and polymer technology. This demand highlights allylamine's significance in various industrial applications and its potential for future growth.

A detailed overview of production cost analysis that evaluates the manufacturing process of allylamine is crucial for stakeholders considering entry into this sector. Furthermore, stakeholders can make informed decisions based on the latest economic data, technological innovations, production process, requirements of raw materials, utility and operating costs, capital investments by major players, pricing strategies, and profit margins.

Below are the sections that further detail the comprehensive scope of the prefeasibility report for an allylamine production plant:

Market Dynamics and Trends: Factors such as rising demand from agrochemical industry are significantly affecting market conditions in the allylamine sector. It is used in the synthesis of herbicides and pesticides that enhance crop yields and protect against pests. As global agricultural practices evolve to meet increasing food demands, the need for effective crop protection solutions drives the demand for allylamine-based products. In 2024, crop production is on the rise; for example, India is projected to achieve a record wheat production of 114 million metric tons, with harvested areas reaching 32 million hectares.

Moreover, the Food and Agriculture Organization (FAO) reported that while agricultural land has declined by 91 million hectares between 2000 and 2022, the demand for efficient pest control methods has become increasingly critical to maintain crop yields. This underscores the importance of agrochemicals, including allylamine derivatives, in developing effective herbicides and pesticides. Understanding these trends helps businesses align their production plans in the allylamine market.

Profiling of Key Industry Players: Leading manufacturers like BASF SE and Alkyl Amines Chemicals Ltd are included in the allylamine report. Recently, BASF announced a strategic initiative to enhance its production capabilities for alkylamines, including allylamine, to meet the growing demand in pharmaceuticals and agrochemicals. Additionally, Alkyl Amines Chemicals Ltd has expanded its research and development efforts to innovate new allylamine derivatives, reflecting the increasing need for effective agricultural chemicals in response to global food security challenges.

Economic Analysis: Capital expenditure (CAPEX) analysis provides stakeholders the knowledge about required investments in advanced technologies, efficient machinery, and necessary infrastructure. Investing in high-capacity mixing equipment, such as a continuous mixer or high-shear mixer, can improve production efficiency by 20-30%. Investing in energy-efficient systems, such as combined heat and power (CHP) systems could reduce energy consumption by up to 30%, as these systems use waste heat from production processes to generate electricity and provide heating.

Fluctuations in allylamine prices are influenced by several key factors, particularly the costs of essential raw materials such as allyl chloride and propylene. The price of allyl chloride is particularly volatile as it closely tied to crude oil prices and supply-demand dynamics in the chemical industry. Geopolitical tensions and trade disputes can further complicate supply chains and cost of these raw materials. These factors create a complex pricing environment for allylamine, necessitating adaptive strategies by makers.

Establishing an allylamine manufacturing facility requires a comprehensive financial investment that encompasses various elements critical to the project's success. The following sections detail these components:

Projected profit margins and effective product pricing strategies improve overall profitability. Manufacturers might target a profit margin of around 20-30%, achieved through strategic pricing based on raw material costs and prevailing market demand. Effective pricing strategies should consider fluctuations in raw material prices and competitive positioning within the market.

This prefeasibility report aims to equip potential investors and existing manufacturers with crucial insights to make informed decisions in the allylamine industry.

*While we strive to always give you current and accurate information, the numbers depicted on the website are indicative and may differ from the actual numbers in the main report. At Expert Market Research, we aim to bring you the latest insights and trends in the market. Using our analyses and forecasts, stakeholders can understand the market dynamics, navigate challenges, and capitalize on opportunities to make data-driven strategic decisions.*

Get in touch with us for a customized solution tailored to your unique requirements and save upto 35%!

Basic Plan

USD 2,699

USD 2,429

Get Startedtax inclusive*

Raw Material and Product Specification, Raw material consumption, Process flow diagram

Machinery Cost, Working Capital

Utilities consumption, Operating cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Raw material consumption and prices, Utilities consumption breakdown, By-Product Credit, Labour Charges Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Get Startedtax inclusive*

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Breakdown of machinery cost by equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Cost of Construction, Plant Building, Site Development Charges

Land Cost, Development Charges

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Basic Plan

USD 2,699

USD 2,429

Key Processing Information

Raw Material and Product Specification, Raw Material Consumption, Process Flow Diagram

Capital Investment Analysis

Machinery Cost, Working Capital

Conversion Cost Analysis

Utilities Consumption, Operating Cost, Overheads, Financing Charges, GSA , Packaging

Premium Plan

USD 3,699

USD 3,329

All Contents of Basic Report

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis

Variable Cost Breakdown

Raw Material Consumption and Prices, Utilities Consumption, Breakdown By-Product Credit, Labour Charges Breakdown

Investing Cost Breakdown

Land and Site Cost, Equipment Cost, Auxiliary Equipment Cost, Contingency, Engineering and Consulting Charges

Enterprise Plan

USD 4,799

USD 4,079

Includes all Report Content

Key Processing Information, Capital Investment Analysis, Conversion Cost Analysis, Variable Cost Breakdown, Investing Cost Breakdown,

Equipment Cost Breakdown

Breakdown of Machinery Cost By Equipment, Auxiliary Equipment Cost, Piping, Electrical, Instrumentation

Land and Construction Cost Details

Land Cost, Development Charges, Cost of Construction, Plant Building, Site Development Charges

Dynamic Excel Cost Model

Dynamic Spreadsheet (Unlocked)

*Please note that the prices mentioned below are starting prices for each bundle type. Kindly contact our team for further details.*

Flash Bundle

Number of Reports: 3

20%

tax inclusive*

Small Business Bundle

Number of Reports: 5

25%

tax inclusive*

Growth Bundle

Number of Reports: 8

30%

tax inclusive*

Enterprise Bundle

Number of Reports: 10

35%

tax inclusive*

How To Order

Our step-by-step guide will help you select, purchase, and access your reports swiftly, ensuring you get the information that drives your decisions, right when you need it.

Select License Type

Choose the right license for your needs and access rights.

Click on ‘Buy Now’

Add the report to your cart with one click and proceed to register.

Select Mode of Payment

Choose a payment option for a secure checkout. You will be redirected accordingly.

Gain insights to stay ahead and seize opportunities.

Get insights & trends for a competitive edge.

Track prices with detailed trend reports.

Analyse trade data for supply chain insights.

Leverage cost reports for smart savings

Enhance supply chain with partnerships.

Connect For More Information

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

Our expert team of analysts will offer full support and resolve any queries regarding the report, before and after the purchase.

We employ meticulous research methods, blending advanced analytics and expert insights to deliver accurate, actionable industry intelligence, staying ahead of competitors.

Our skilled analysts offer unparalleled competitive advantage with detailed insights on current and emerging markets, ensuring your strategic edge.

We offer an in-depth yet simplified presentation of industry insights and analysis to meet your specific requirements effectively.

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City,1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

United States

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

United States (Head Office)

30 North Gould Street, Sheridan, WY 82801

+1-415-325-5166

Australia

63 Fiona Drive, Tamworth, NSW

+61-448-061-727

India

C130 Sector 2 Noida, Uttar Pradesh 201301

+91-723-689-1189

Philippines

40th Floor, PBCom Tower, 6795 Ayala Avenue Cor V.A Rufino St. Makati City, 1226.

+63-287-899-028, +63-967-048-3306

United Kingdom

6 Gardner Place, Becketts Close, Feltham TW14 0BX, Greater London

+44-753-713-2163

Vietnam

193/26/4 St.no.6, Ward Binh Hung Hoa, Binh Tan District, Ho Chi Minh City

+84-865-399-124

Share